Understanding the Chinese Mold Manufacturing Landscape

China has emerged as a global powerhouse in mold manufacturing, playing a pivotal role in the international market. With a vast number of manufacturing facilities across the country, China's mold production volume has been steadily increasing over the years. In 2023, China's mold output reached 2695.88 million sets, demonstrating a 2.56% growth compared to the previous year, according to industry reports. This growth trend is expected to continue as the manufacturing industry in China expands further.

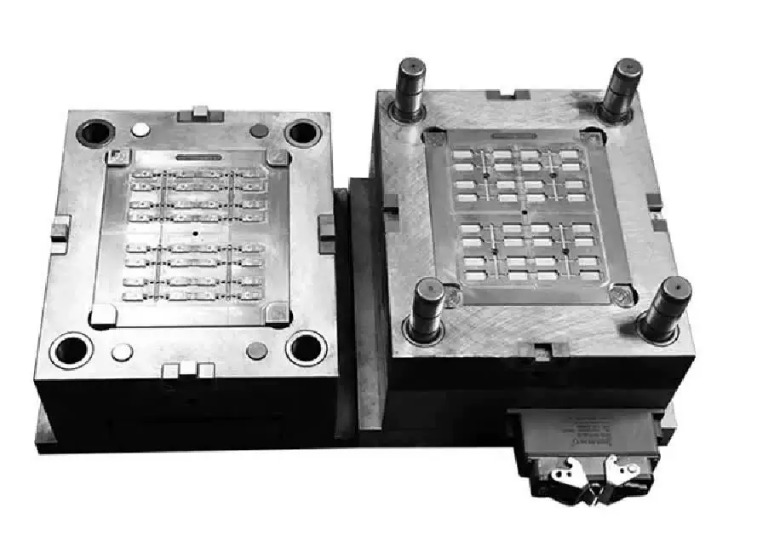

The range of molds produced in China is incredibly diverse, catering to various industries. From plastic injection molds widely used in the consumer electronics and household appliance sectors to die - casting molds essential for the automotive and aerospace industries, Chinese manufacturers have the capabilities to meet different demands. For instance, in the automotive industry, China's mold manufacturers supply a significant portion of the molds required for vehicle production, including complex body panel molds and engine component molds.

In terms of technology, Chinese mold manufacturers have been making remarkable progress. Many leading enterprises have adopted advanced CAD/CAM/CAE technologies, which enable them to design and manufacture molds with higher precision and efficiency. High - speed machining, precision EDM (Electrical Discharge Machining), and 3D printing technologies are also being increasingly used in the mold manufacturing process. These technological advancements have not only improved the quality of the molds but also reduced the production cycle.

However, with the large number of mold manufacturers in China, which exceeds 300,000 according to some estimates, the quality and reliability of products can vary significantly. This is why choosing a reliable mold manufacturer in China becomes crucial. A reliable manufacturer can ensure high - quality products, on - time delivery, and excellent after - sales service, which are essential factors for the success of any project that involves mold - made products.

Key Factors to Consider

Reputation and Experience

Reputation is a crucial indicator of a mold manufacturer's reliability. Start by checking the company's official website. A professional - looking website with detailed information about their services, past projects, and client testimonials is a good sign. For example, a manufacturer that showcases a diverse range of successful projects on its website demonstrates its capabilities.

Customer reviews are also invaluable. Platforms like Alibaba.com and Made - in - China.com often have review sections where previous clients share their experiences. Positive reviews highlighting factors such as high - quality products, on - time delivery, and excellent customer service can give you confidence in the manufacturer. Industry reports can also provide insights into a manufacturer's standing within the industry.

Experience matters a great deal in mold manufacturing. A manufacturer with many years in the business, say over 10 years, is more likely to have mastered various manufacturing processes. They have likely encountered and solved a wide range of problems, which means they can better handle any issues that may arise during your project. For instance, an experienced manufacturer will be more proficient in complex mold designs and can offer more accurate advice on material selection.

Quality Assurance

A robust quality assurance system is non - negotiable. ISO certifications, such as ISO 9001, are internationally recognized standards that demonstrate a manufacturer's commitment to quality management. A mold manufacturer with ISO 9001 certification has established procedures for every stage of production, from design to delivery.

The choice of raw materials significantly impacts the quality of the final mold. High - quality steel for metal molds or top - grade plastic resins for plastic molds ensure durability and performance. For example, using premium - grade P20 steel in injection molds can enhance the mold's lifespan and the quality of the molded products.

During the production process, strict monitoring is essential. This includes regular checks on machining accuracy, heat treatment processes (for metal molds), and plastic injection parameters (for plastic molds). Manufacturers should also conduct comprehensive product testing. This can involve dimensional accuracy testing using coordinate measuring machines (CMM), hardness testing for metal molds, and functional testing to ensure the mold meets all performance requirements.

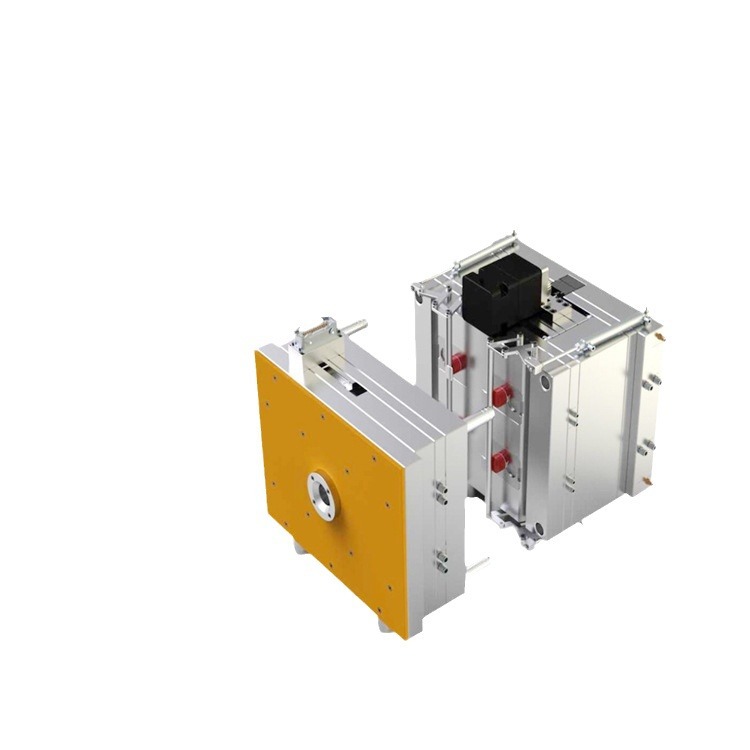

Production Capacity and Capabilities

The production capacity of a mold manufacturer can vary greatly depending on its size and resources. Consider the following comparison table:

| Manufacturer Size | Monthly Mold Production Capacity | Equipment |

| Small - scale (less than 50 employees) | 10 - 30 sets | Basic machining tools like CNC milling machines, lathes, and simple EDM machines |

| Medium - scale (50 - 200 employees) | 30 - 100 sets | A wider range of advanced CNC machines, high - precision EDM machines, and some automation equipment |

| Large - scale (over 200 employees) | 100+ sets | State - of - the - art CNC machining centers, high - speed EDM machines, and automated production lines |

In terms of capabilities, a reliable mold manufacturer should have in - house mold design capabilities. They should be proficient in using CAD/CAM software, such as SolidWorks, UG, or Pro/E, to create accurate and optimized mold designs. Regarding manufacturing processes, they should be well - versed in processes like high - speed machining, precision EDM, and wire - cutting. The availability of advanced equipment like 5 - axis CNC machining centers can also greatly enhance the manufacturer's ability to produce complex molds with high precision.

Cost - Effectiveness

The cost of a mold is composed of several elements:

- Material Costs: This includes the cost of raw materials such as steel, aluminum, or plastic resins, which typically account for 15% - 30% of the total mold cost.

- Design Costs: Usually around 10% - 15% of the total cost, covering the efforts of mold designers.

- Processing Costs: Comprising machining, heat treatment, and surface treatment costs, which can make up 30% - 50% of the total cost.

- Overhead Costs: Such as factory rent, equipment depreciation, and labor costs for non - production staff.

- Profit Margin: The manufacturer's profit, which is also factored into the price.

While cost is an important consideration, it should not be the sole determining factor. A very low - priced mold may be of inferior quality, leading to issues like short lifespan, frequent breakdowns, and poor - quality molded products. You need to balance the cost with the quality, service, and long - term costs. For example, a slightly more expensive mold from a reliable manufacturer may save you money in the long run due to its better performance and longer lifespan.

Communication and Customer Service

Effective communication is the cornerstone of a successful partnership with a mold manufacturer. From the initial inquiry stage, the manufacturer should respond promptly. For example, if you send an email with your project requirements, a reliable manufacturer will reply within 24 hours, acknowledging your request and providing initial information.

They should also be able to understand your requirements clearly. This may involve asking detailed questions about the product design, production volume, and any specific performance requirements. A good manufacturer will then provide solutions based on their expertise. For instance, if you have a complex product design, they may suggest design modifications to make the mold manufacturing process more efficient without sacrificing product functionality.

During the production process, regular communication on the project progress is essential. They should be able to provide you with updates on a weekly or bi - weekly basis, depending on the project's duration, and promptly address any concerns or questions you may have. After - sales service is also crucial, including assistance with mold maintenance, repair, and troubleshooting.

Case Studies: Success Stories and Cautionary Tales

Success Story: A Seamless Collaboration in the Automotive Industry

A European automotive company was in search of a reliable mold manufacturer to produce high - precision injection molds for their new car model's interior components. After a thorough evaluation, they chose a Chinese mold manufacturer with over 15 years of experience in the automotive mold sector.

The manufacturer had a strong reputation, as evidenced by its long - standing relationships with other major automotive brands. Their in - house design team, proficient in using the latest CAD/CAM software, worked closely with the European company's design engineers. They were able to optimize the mold design to reduce production costs without sacrificing quality.

During production, the Chinese manufacturer strictly adhered to the quality assurance system, using high - quality steel and conducting regular inspections. The production capacity of the manufacturer, with a monthly output of over 50 sets of complex molds, ensured that the project was completed on time. The molds produced met all the performance requirements, and the parts molded from these molds had excellent dimensional accuracy and surface finish. This successful collaboration led to a long - term partnership, with the European company continuing to source molds from the Chinese manufacturer for subsequent projects.

Cautionary Tale: The Consequences of Choosing an Unreliable Manufacturer

A small - scale electronics startup in the United States decided to outsource the production of plastic injection molds for their new smart device to a low - cost Chinese mold manufacturer they found online. The manufacturer had a limited online presence and only a few years of experience.

The initial communication was promising, with quick responses from the manufacturer. However, as the project progressed, problems began to surface. The manufacturer failed to understand the startup's complex design requirements fully, resulting in multiple design revisions that extended the production timeline.

During production, quality issues emerged. The raw materials used were of inferior quality, leading to molds with inconsistent wall thicknesses and poor surface finishes. The startup received the first batch of molds much later than the agreed - upon delivery date. When they tested the molds, they found that many of them were defective, causing significant delays in their product launch. The cost of re - designing the molds, sourcing new materials, and finding a new manufacturer to rectify the issues ended up being much higher than if they had chosen a more reliable mold manufacturer from the start. This case highlights the importance of thoroughly evaluating a mold manufacturer before entering into a contract.

Yigu Technology's Perspective

As a custom supplier of non - standard plastic and metal products, Yigu Technology believes that when choosing a mold manufacturer, it is essential to focus on its design and manufacturing capabilities for non - standard products. A reliable manufacturer should be able to understand and translate unique design requirements into high - quality molds.

Flexibility in handling customization needs is also crucial. Non - standard products often require special materials, complex structures, and unique manufacturing processes. A good mold manufacturer should be able to adapt its production lines and techniques to meet these demands. For example, Yigu Technology values manufacturers who can quickly adjust their design and production based on feedback, ensuring that the final product meets the exacting standards of non - standard projects.

FAQ

Q1: How can I verify the quality of a mold manufacturer's products?

You can verify the quality by checking the manufacturer's certifications like ISO 9001, which indicates a well - established quality management system. Request samples and conduct thorough tests, such as dimensional accuracy testing with a coordinate measuring machine (CMM), hardness testing for metal molds, and functional testing to ensure the mold meets your performance requirements. Visiting the factory to observe their production processes and quality control measures can also provide first - hand information about the quality of their products.

Q2: What if the mold manufacturer fails to meet the delivery time?

Before signing the contract, clearly define the delivery time and include penalty clauses for delays. For example, specify that for each day of delay, the manufacturer will pay a certain percentage of the total contract price as a penalty. If the manufacturer fails to meet the delivery time, first, communicate with them to understand the reasons and try to negotiate a solution, such as an adjusted delivery time and appropriate compensation. If negotiations fail, you may consider taking legal measures according to the contract terms.

Q3: Is it necessary to visit the mold manufacturer in person?

Visiting the mold manufacturer in person is highly recommended, especially for large - scale or high - precision projects. It allows you to directly assess their production equipment, such as the type and condition of CNC machines, EDM equipment, and inspection tools. You can also observe their manufacturing processes, from raw material handling to the final product assembly, and evaluate their factory management, including quality control procedures, employee skills, and work environment. This on - site visit provides a more comprehensive understanding of the manufacturer's capabilities and helps you make a more informed decision.