Introduction: Making Steel Work Better

When people hear "laser printing on steel," they usually think of simple part numbers or company logos burned onto metal surfaces. While this is true, it's only a small part of what modern laser technology can do. Today, lasers aren't just tools for making marks - they're precise instruments that can completely change how steel surfaces work. Instead of just making things look good, we now focus on making surfaces perform better. This process uses carefully controlled laser energy to change the basic physical and chemical properties of steel surfaces, creating features that were impossible or too expensive to make before. We can now design surfaces that resist wear better, fight off rust and corrosion, and have specific visual properties. This article goes beyond basic marking to explore how laser technology can transform steel, including advanced marking techniques for color and contrast, protective laser coating applications, and the thorough testing methods that prove these improvements work in real-world conditions.

Different Types of Laser Marking

The ability to create permanent, high-quality marks on steel is essential across many industries, from medical devices to airplane parts. However, not all marks are the same. The type of laser process you choose determines how the mark looks, how long it lasts, and how it affects the steel underneath. Understanding the science behind these techniques is important for picking the best solution for your specific needs, whether you want bright colors, deep black contrast, or protection against rust.

Heat Treatment vs. Cutting Away Material

Controlling the color of marks on stainless steel, especially on medical-grade 316L steel, is often required. The two main methods, laser heat treatment and laser cutting, work in completely different ways.

Cutting (or engraving) removes material. A high-power laser beam focuses on the steel surface and delivers enough energy to turn the material into vapor, removing it completely. This creates a physical dent in the surface, making a mark with actual depth. While this type of mark lasts a long time, the process damages the surface. It removes material, makes the surface rough, and can damage the natural protective layer that gives stainless steel its ability to resist rust. The resulting mark is usually a dull gray or whitish color, showing the raw, textured material underneath.

Heat treatment (or annealing) works differently by using heat to transform the surface. It uses a lower power laser to heat the steel surface in a very controlled way, always keeping the temperature below the point where the material would melt. This localized heating causes a thin, clear layer of oxide to grow on the surface. The color you see isn't from paint or dye but from a structural effect called thin-film interference. When light passes through the oxide layer, it reflects off both the top of the oxide and the steel surface below. Depending on how thick the oxide layer is - which is precisely controlled by laser settings like speed and power - certain colors of light work together to produce bright, consistent colors like brown, purple, blue, and green. Most importantly, this process doesn't remove any material and keeps the smooth surface finish, leaving the protective layer intact.

| Feature | Laser Heat Treatment | Laser Cutting |

| How It Works | Localized heating, oxide layer growth | Material vaporization, removal |

| Surface Quality | Smooth, non-damaging, keeps protective layer | Rough, material removed, can create rust spots |

| Result | Colored marks (blue, brown, green, etc.) | A rough, deep mark (usually gray/white) |

| Material | Mainly on stainless steels (like 316L), titanium | Most metals, plastics, and other materials |

| Best For | Medical device marking, branding, rust-sensitive parts | Deep marks for part numbers, harsh environments |

Creating "True Black" Marks

Making a deep, non-shiny black mark on stainless steel is particularly challenging. Traditional fiber lasers, while good for many jobs, often produce a dark gray or charcoal mark that still reflects some light. This happens because their longer pulse duration mainly creates a heat effect, making a dark oxide layer that works but isn't optically perfect. For applications that need the highest contrast and minimal glare, a more advanced solution is needed.

The answer lies in ultrashort pulse lasers, specifically those working in picosecond and femtosecond time ranges. A femtosecond is one quadrillionth of a second. The extremely short pulse duration and incredibly high peak power of these lasers enable a process called "cold" removal. The energy is delivered to the material so quickly that heat doesn't have time to spread to the surrounding area. Instead of melting and oxidizing the surface, the laser energy directly transforms the material and causes microscopic nanostructures to form by themselves.

These structures are called Laser-Induced Periodic Surface Structures (LIPSS). On stainless steel, they form a complex, layered landscape of cones, ripples, and tiny holes on a scale smaller than the wavelength of visible light. This nanostructured surface acts like a nearly perfect light trap. Light enters the structure and bounces around multiple times within the microscopic features, with some energy being absorbed at each bounce. Very little light reflects back to the observer, creating a deep, rich, non-reflective black that looks the same from any viewing angle. In applications requiring high-contrast readability for machine vision systems or minimal reflection for optical instruments, femtosecond black marking on stainless steel provides unmatched performance. The resulting mark isn't a coating; it's an integral part of the surface and therefore extremely durable.

Laser Coating for Strengthening

Laser coating, also known as Laser Metal Deposition (LMD), is a powerful manufacturing process that goes far beyond marking. It's a method of strengthening a component by metallurgically bonding a layer of high-performance material onto a lower-cost base material. This allows for creating hybrid parts that combine the bulk properties and cost-effectiveness of a common material like mild steel with the exceptional surface properties of a superalloy. The process transforms a standard component into one capable of withstanding extreme wear, corrosion, or high-temperature environments.

Laser Coating Basics

The laser coating process is precise and highly controlled, resulting in a superior bond and minimal warping compared to traditional welding techniques. The basic steps are:

1. Preparation: The base material, such as a mild steel shaft or flange, is thoroughly cleaned to remove any dirt or chemicals that could interfere with the bonding process. The area to be coated is precisely marked.

2. Material Application: A fine powder or wire of the desired coating material is fed through the same path or from the side into the laser beam. The delivery rate of this material is carefully controlled to ensure consistent layer thickness.

3. Laser Melting: A high-power laser beam, often from a diode or fiber laser, focuses on the base material. The laser energy creates a small, shallow molten pool on the surface. The applied powder or wire melts at the same time as it enters this pool.

4. Metal Bonding: The molten coating material mixes with the thin molten layer of the base material. As the laser moves across the part, this mixture rapidly cools and hardens, forming a new, dense, completely solid layer. This creates a true metallurgical bond, where the atomic structures of the two materials are fused together. The resulting coated layer is an integral part of the component, not just a mechanical coating that can chip or peel off.

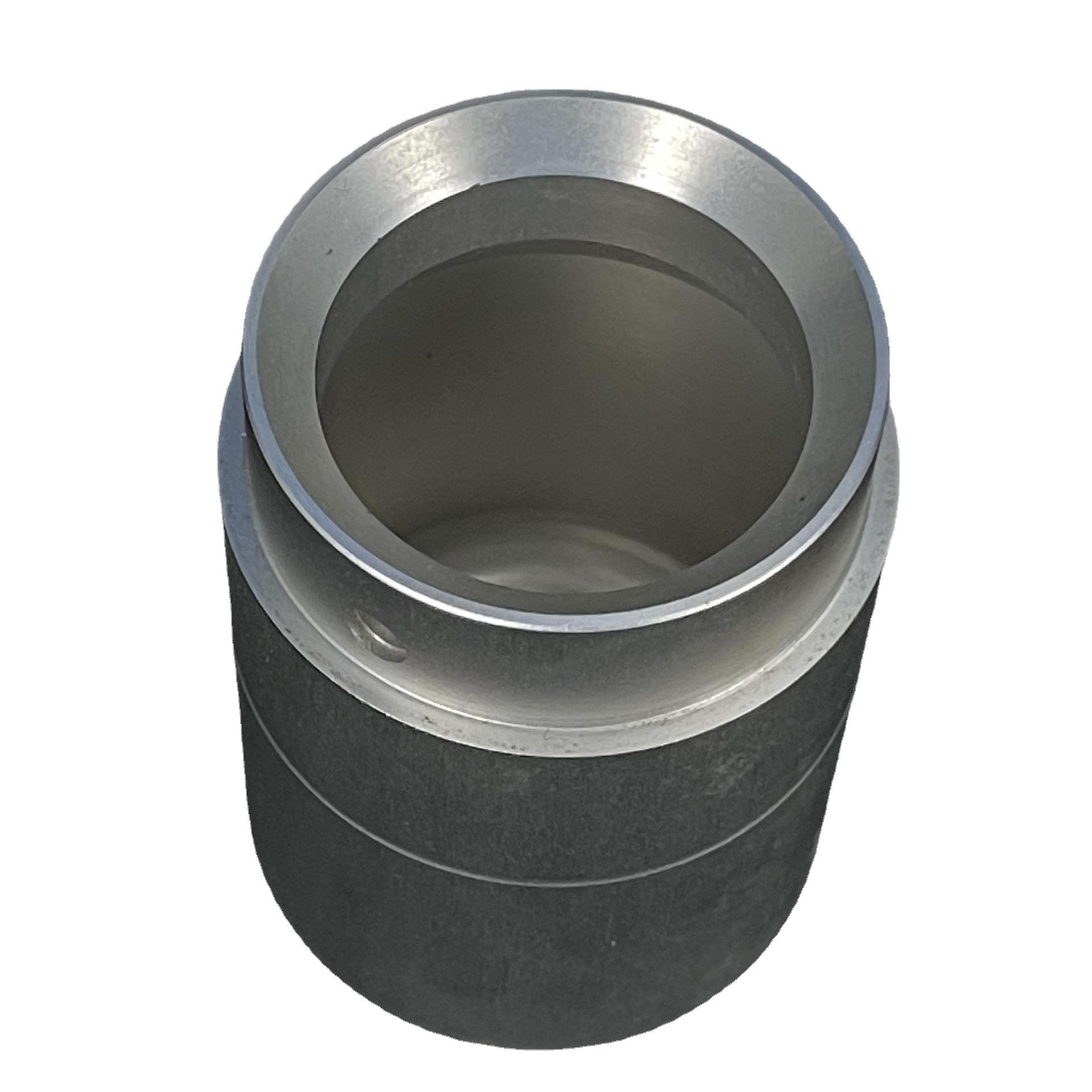

Case Study: Wear-Resistant Coatings

A primary use for laser coating is to make components last longer when they're subjected to intense mechanical wear and scraping. By coating a targeted surface area of an inexpensive mild steel part, its service life can be dramatically extended.

Material 1: Stellite (e.g., Stellite 6)

Stellite is a family of cobalt-chromium alloys known for their exceptional hardness and resistance to metal-to-metal wear, particularly at high temperatures. Its composition, rich in hard particles within a tough cobalt base, makes it ideal for high-friction applications. A classic example is coating the sealing surface of a valve seat made from mild steel. The bulk of the valve can be made from low-cost steel, providing the necessary structural strength. The critical contact surface, however, is coated with a thin layer of Stellite 6. This provides the extreme hardness and resistance to sticking needed to withstand repeated opening and closing cycles against the valve plug, preventing wear and ensuring a tight seal over a long operational life.

Material 2: Inconel (e.g., Inconel 625)

Inconel is a family of nickel-chromium-based superalloys known for outstanding strength and resistance to corrosion and oxidation, especially at extreme temperatures, both high and very cold. Inconel 625, in particular, offers excellent protection against pitting and crack corrosion in aggressive chemical environments. An example application is repairing or improving components used in marine or chemical processing industries. A shaft or pump part made from mild steel can be quickly damaged by saltwater or corrosive chemicals. By applying a laser-coated layer of Inconel 625, the part is protected by a strong, unreactive barrier. This protects the underlying steel from chemical attack, significantly extending the component's life and preventing costly downtime.

Practical results show that coating a mild steel shaft with Stellite 6 can increase its surface hardness from approximately 180 HV to over 400 HV. In high-wear industrial applications, this often means a 3-to-8-fold increase in how long the component lasts.

Testing Performance Under Tough Conditions

Making claims about better durability and corrosion resistance is easy; proving them requires thorough, standardized testing. For laser-treated surfaces to be trusted in critical applications, their performance must be validated against industry-accepted standards. This section details the testing methods used to provide solid evidence that laser-treated surfaces deliver measurable, repeatable, and certified performance benefits, building the trust required by engineers and materials scientists.

Comparing Corrosion Resistance

In industries like medical and food processing, maintaining the corrosion resistance of stainless steel is absolutely essential. The marking process itself must not damage the material's protective qualities. Here, the difference between laser heat treatment and traditional chemical etching becomes very clear.

Chemical etching's main problem is its destructive nature. The process uses strong acids to dissolve the surface of the steel to create a mark. In doing so, it completely removes the protective chromium-oxide layer that is responsible for stainless steel's ability to resist rust. This not only leaves the raw, unprotected steel underneath exposed to the environment but can also create tiny cracks. These cracks become ideal starting points for localized corrosion, such as pitting and crevice corrosion, especially when exposed to chlorides (like salt or cleaning agents). Rust can form within the etched mark and spread out onto the surrounding surface, compromising both cleanliness and appearance.

Laser heat treatment, on the other hand, strengthens the very layer that chemical etching destroys. The controlled heating process grows a thicker, more stable, chromium-rich oxide layer on the surface. It doesn't disrupt the original protective layer but rather makes it stronger. This enhanced oxide layer is more robust and significantly more resistant to chloride ion attack than both the original surface and a chemically etched surface. When subjected to corrosion testing, the results are clear.

- Surface Quality: Laser Heat Treated (Maintained) vs. Etched (Damaged)

- Protective Layer: Laser Heat Treated (Enhanced) vs. Etched (Removed/Damaged)

- Corrosion Test Result: Laser Heat Treated (Pass) vs. Etched (Fail)

In side-by-side tests, a chemically etched part will show signs of rust starting from the mark, while the laser heat-treated part remains completely clean.

Proving QR Code Permanence

In modern manufacturing, a QR code isn't just for marketing; it's a critical data carrier for tracking parts throughout their entire lifetime. It must remain scannable throughout the part's entire lifecycle, which can involve rough manufacturing steps, harsh chemical washes, outdoor exposure, and years of operational wear. A printed label or shallow etch will inevitably fail under these conditions. Proving the permanence of a laser-marked QR code requires subjecting it to the most demanding accelerated life tests.

The gold standard for simulating a corrosive environment is the ASTM B117 Salt Spray Test. This internationally recognized standard provides a controlled corrosive environment to produce relative corrosion resistance information for metal specimens. Our validation process involves placing a 316L stainless steel sample, marked with a deep heat-treated or ultrashort pulse black-marked QR code, into a calibrated salt spray chamber. The chamber maintains a continuous, dense fog of 5% sodium chloride solution at a constant temperature of 35°C. This aggressive environment rapidly attacks any weakness in the material's surface. We conduct scanning tests on the QR code with industrial scanners after 96, 240, and even 500 hours of continuous exposure. The goal is to verify that the mark's contrast and quality are maintained and that scanning success remains at 100%, long after printed labels have dissolved and chemically etched marks have become unclear due to corrosion. Passing this test provides clear proof that the laser mark is a permanent part of the steel itself.

Conclusion: The Future is About Function

The concept of laser printing on steel has evolved far beyond its origins. It's no longer just about placing a mark on a surface; it's about strategically engineering that surface for superior performance. By harnessing the precise energy of a laser beam, we can fundamentally change a material's properties to meet the ever-increasing demands of modern industry. From creating corrosion-proof colored marks on medical implants to coating industrial shafts with wear-resistant superalloys, laser surface treatment is a key enabling technology for innovation.

- Beyond Marking: The term laser printing on steel has evolved to include surface improvement, fundamentally changing a material's properties.

- Precise Control: Laser processes like heat treatment and ultrashort pulse marking offer unmatched control over color, contrast, and surface quality.

- Better Performance: Laser coating enables creating hybrid components, combining the low cost of mild steel with the superior wear and corrosion resistance of superalloys like Stellite and Inconel.

- Proven Durability: The benefits aren't just theoretical; they're proven through standardized tests like ASTM B117, ensuring reliability in the most demanding environments.

As manufacturing pushes the boundaries of performance, efficiency, and longevity, the ability to improve surfaces with precision and repeatability will become increasingly important. The future of laser technology on steel isn't just about the mark you can see, but the performance you can measure.