Plastic mold injection molding offers unmatched efficiency and design flexibility for high-volume production but requires significant upfront investment and design constraints that make it less suitable for low-volume applications.

When considering manufacturing options for plastic components, plastic mold injection molding often emerges as the leading candidate—but understanding its full implications is crucial for making informed decisions. This manufacturing process involves injecting molten plastic into precisely engineered molds under high pressure, creating identical parts with remarkable speed and consistency. However, its suitability depends entirely on your specific project requirements, production volumes, budget, and timeline. This comprehensive analysis goes beyond simple pros and cons to provide engineers, product designers, and business decision-makers with a detailed, balanced perspective. We'll explore not just how the process works, but when it delivers exceptional value and when alternative methods might be more appropriate. By examining real-world applications, cost structures, and industry-specific considerations, this guide will help you determine if injection molding aligns with your manufacturing strategy.

Introduction

Plastic mold injection molding stands as one of the most dominant manufacturing processes worldwide, responsible for producing countless everyday items and sophisticated technical components alike. Its appeal lies in its ability to create complex, high-precision plastic parts with exceptional efficiency once initial setup is complete. However, this manufacturing method presents a classic trade-off: substantial upfront costs versus long-term per-unit savings. For companies developing new products or evaluating manufacturing approaches, understanding this balance is critical. This article provides a thorough, objective examination of injection molding's strengths and limitations. We'll explain the technical process, analyze its advantages in depth, address its disadvantages honestly, compare material options, and break down cost considerations relative to other methods. Whether you're planning a consumer product launch or engineering medical devices, this information will help you navigate the decision-making process with greater confidence and clarity.

What Is Plastic Mold Injection Molding?

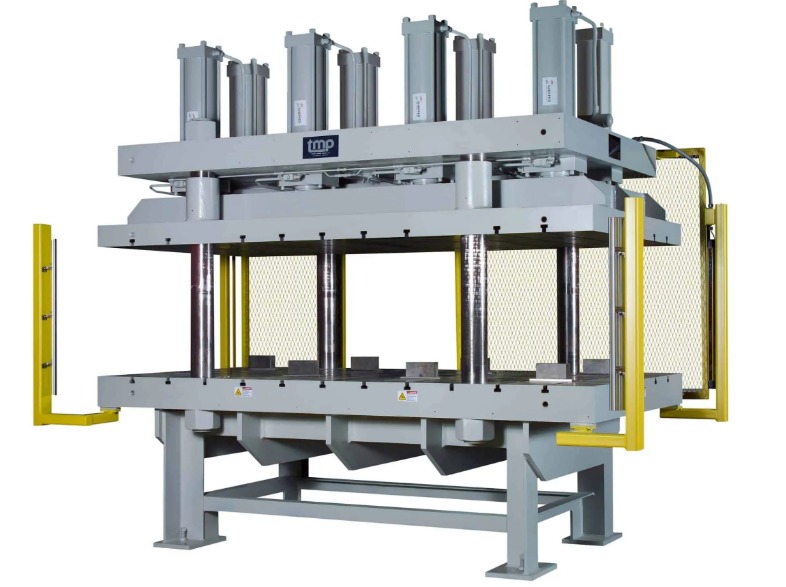

Plastic mold injection molding is a manufacturing process for producing plastic parts by injecting molten plastic material into a custom-made mold cavity, where it cools and solidifies into the final shape. The process is characterized by its use of specialized machinery (injection molding machines) and precision-engineered molds (typically made from tool steel or aluminum). What distinguishes injection molding from other plastic forming methods is its combination of high pressure, precise temperature control, and automated cycle repetition. This enables the production of parts with intricate geometries, excellent surface finishes, and tight tolerances that would be difficult or impossible to achieve with other methods like thermoforming or extrusion.

The process is fundamentally suited for high-volume production where the initial mold investment can be justified by the economies of scale achieved through rapid, automated manufacturing. A single mold can often produce hundreds of thousands to millions of identical parts with minimal variation, making injection molding particularly valuable for standardized components across industries from consumer goods to automotive manufacturing.

How Does the Process Work?

The injection molding process follows a precise, cyclical sequence that transforms raw plastic material into finished components. Understanding this workflow helps in appreciating both the capabilities and constraints of the method.

- Clamping: The two halves of the mold are securely closed and held together by the clamping unit of the injection molding machine. Tonnage pressure must exceed the injection pressure to prevent the mold from flashing (leaking plastic at the seam).

- Injection: Plastic material (usually in granular form) is fed from a hopper into a heated barrel where it melts. A reciprocating screw or ram injector then forces the molten plastic under high pressure (typically 500-2,000+ psi) into the mold cavity through a sprue and runner system.

- Cooling: The plastic inside the mold begins to cool and solidify, taking the shape of the cavity. Cooling time depends on part thickness and material properties and represents a significant portion of the total cycle time.

- Ejection: Once sufficiently solidified, the mold opens, and ejector pins push the finished part(s) out of the mold. The mold then closes again, and the cycle repeats.

Cycle times can range from a few seconds for small, simple parts to minutes for large, complex components. Modern injection molding machines often operate with robotic automation for part removal, runner separation, and even in-line quality inspection, further enhancing efficiency and consistency.

What Are the Key Advantages?

Injection molding offers several compelling benefits that explain its widespread adoption across industries.

High Efficiency and Production Speed

Once the mold is created and the process parameters are optimized, injection molding achieves remarkable production efficiency. Modern machines can complete cycles in as little as 10-30 seconds for many small to medium-sized parts. This speed, combined with the ability to use multi-cavity molds (producing multiple identical parts per cycle) and family molds (producing different but related parts per cycle), results in exceptionally high output rates. For example, a manufacturer of disposable medical components might use a 64-cavity mold to produce thousands of parts per hour, achieving unit costs that are fractions of a cent.

- Design Complexity and Precision: Injection molds can create intricate geometries with features like undercuts, threads, living hinges, and textured surfaces in a single operation. Tolerances as tight as ±0.001 inches (0.025 mm) are achievable with proper mold design and process control, reducing or eliminating secondary operations.

- Material and Finish Versatility: The process accommodates thousands of thermoplastic materials with varying properties (flexibility, strength, transparency, chemical resistance). Parts emerge from the mold with excellent surface finishes that can range from textured to glossy, often eliminating the need for post-processing.

- Minimal Material Waste: Unlike subtractive manufacturing methods, injection molding is inherently efficient with material. Any excess (sprue, runners) can often be reground and recycled back into the process, especially with hot runner systems that keep material molten in the channels.

- Labor Efficiency and Consistency: The high level of automation in modern injection molding reduces direct labor requirements while ensuring exceptional consistency between parts. Automated vision systems and sensors can provide real-time quality monitoring, maintaining quality across long production runs.

What Are the Main Disadvantages?

Despite its advantages, injection molding presents significant challenges that must be carefully considered.

High Initial Tooling Investment

The most substantial barrier is the cost and time required for mold (tool) design and fabrication. A single production-grade steel mold for a moderately complex part can cost anywhere from $10,000 to over $100,000, with development timelines spanning 4 to 16 weeks. This investment is justifiable only with sufficient production volumes to amortize the cost. This creates significant financial risk for new product launches with uncertain market demand.

- Design Limitations and Lead Time: Part design is heavily constrained by the need for proper draft angles (for ejection), uniform wall thickness (to prevent defects), and the avoidance of certain geometries that are difficult to mold. Once a mold is made, design changes are extremely expensive and time-consuming, often requiring welding, re-machining, or even starting over with a new mold.

- Size Limitations: While machines exist for very large parts (like automotive bumpers), there are practical limits to part size based on machine clamp force and platen size. Very large molds are exceptionally expensive and require specialized, high-tonnage machines.

- Startup and Process Complexity: Achieving optimal quality requires precise tuning of numerous parameters (temperature, pressure, injection speed, cooling time). This process validation phase can be time-consuming and may produce scrap material before stable production is achieved.

Which Materials Can Be Used?

Injection molding supports an extensive range of thermoplastic materials, each offering distinct properties. The selection directly impacts part performance, cost, and manufacturability.

| Material Category | Common Examples | Key Properties | Typical Applications |

|---|---|---|---|

| Commodity Thermoplastics | Polypropylene (PP), Polyethylene (PE), Polystyrene (PS), ABS | Low cost, good general properties, easy to process. | Packaging, consumer goods, toys, household items. |

| Engineering Thermoplastics | Polycarbonate (PC), Nylon (PA), Acetal (POM), PET, PBT | Enhanced mechanical strength, heat resistance, and durability. | Automotive components, electrical housings, mechanical gears. |

| High-Performance Thermoplastics | PEEK, PEI (Ultem), PPS, LCP | Exceptional thermal stability, chemical resistance, and strength. | Aerospace, medical implants, semiconductor, and extreme environment applications. |

| Elastomers (TPE/TPU) | Thermoplastic Polyurethane, Santoprene® | Flexibility, rubber-like elasticity, and recyclability. | Seals, gaskets, soft-touch grips, wearable device components. |

Material Selection Case: A startup designing a compact, portable water filter needed a housing that was lightweight, durable, and resistant to chemicals and UV light. After consultation with their molding partner, they selected Glass-Filled Nylon (PA6+GF30). While more expensive than ABS, this material provided the necessary structural strength for a thin-walled design and superior environmental resistance, ensuring product reliability—a decision made possible by injection molding's material versatility.

How Do Costs Compare to Other Methods?

Understanding the total cost structure is essential for making accurate comparisons with alternative manufacturing processes.

| Manufacturing Method | Upfront/Tooling Cost | Per-Unit Cost at Low Volume | Per-Unit Cost at High Volume | Best Volume Range |

|---|---|---|---|---|

| Injection Molding | Very High ($10K - $100K+) | High (amortizing tooling) | Very Low (pennies) | High (10,000+) |

| 3D Printing (FDM/SLS) | Very Low (none) | Medium | High (no economy of scale) | Very Low (1-100) |

| CNC Machining | Low (programming only) | Medium | High (labor & machine time intensive) | Low to Medium (1-1,000) |

| Vacuum Casting/Urethane Casting | Medium (master pattern & silicone mold) | Medium | High (mold wears out ~50 parts) | Very Low to Low (10-100) |

The break-even analysis is crucial. For instance, if a part costs $5.00 to CNC machine and $0.50 via injection molding, but the mold costs $20,000, the break-even point would be around 4,444 units ($20,000 / ($5.00 - $0.50)). Below this volume, CNC machining is cheaper; above it, injection molding becomes more economical.

What Industries Benefit Most?

Certain industries derive exceptional value from injection molding due to their specific needs for scale, precision, and material performance.

- Consumer Products & Electronics: High-volume production of everything from bottle caps to smartphone cases and appliance housings. Benefits from design flexibility for aesthetics and ergonomics.

- Automotive: Produces both interior (dash components, knobs) and under-hood parts (connectors, fluid reservoirs). Values the ability to use engineered materials for heat and chemical resistance.

- Medical & Healthcare: Manufactures single-use, sterile components (syringes, IV connectors, surgical trays) and durable device housings. Relies on the process's consistency, cleanliness, and ability to use biocompatible materials.

- Packaging: Dominates the production of containers, lids, and closures. Leverages the ultra-high speed and low per-unit cost achievable with multi-cavity molds.

- Industrial & Consumer Goods: Produces tools, storage containers, and mechanical components where durability and precise fit are required.

Conclusion

Plastic mold injection molding presents a powerful but specific value proposition in the manufacturing landscape. Its unmatched efficiency, material versatility, and ability to produce complex, high-precision parts at scale make it the undisputed champion for high-volume production. However, these advantages come with significant upfront costs, lengthy lead times for tooling, and stringent design rules that create substantial barriers for low-volume applications or products in early development stages. The decision to use injection molding should be driven by a careful analysis of projected volumes, part complexity, available budget, and timeline. By understanding both the profound advantages and the real disadvantages outlined in this guide, product teams can make strategic choices, potentially using prototyping methods like 3D printing or CNC machining for validation before committing to the tooling investment required for full-scale injection molding production. When aligned with the right application, injection molding remains one of the most effective and reliable manufacturing processes available.

Frequently Asked Questions (FAQ)

What is the minimum recommended production volume to justify injection molding tooling costs?

While there's no universal threshold, injection molding typically becomes economically viable at volumes of 5,000 to 10,000 units or more for a single part. The exact number depends entirely on the mold cost, part complexity, and the per-unit cost difference compared to alternative methods (like CNC). For lower volumes (500-5,000 units), aluminum molds (softer, less durable, cheaper) or rapid tooling techniques can sometimes make injection molding feasible.

Can injection molding use recycled plastic materials?

Yes, many thermoplastics used in injection molding can incorporate recycled content or regrind (scrap material from the same process that is ground up and reused). However, the percentage and quality of recycled material must be carefully controlled, as repeated heating or contamination can degrade material properties (chain length, strength, color). Virgin material is often required for critical applications.

How long does a typical injection mold last?

Mold lifespan is measured in shots (cycles). A soft aluminum prototype mold may last only 5,000 to 10,000 shots. A hardened steel production mold, with proper maintenance, can last 1,000,000 shots or more. Factors affecting lifespan include material abrasiveness (glass-filled materials wear molds faster), maintenance frequency, and mold design quality.

What are the most common defects in injection molded parts, and how are they prevented?

Common defects include:

- Sink Marks: Depressions in thick sections. Prevented by designing uniform wall thickness and adequate rib design.

- Warpage: Uneven cooling causes twisting. Prevented by optimizing cooling channels and gate placement.

- Short Shots: Incomplete filling. Prevented by ensuring adequate wall thickness, proper venting, and sufficient injection pressure.

- Flash: Thin plastic on mold seams. Prevented by ensuring adequate clamp force and proper mold maintenance.

Process simulation software (like Moldflow) is often used in the design phase to predict and prevent these issues.

Contact Yigu Technology for Custom Manufacturing.

At Yigu Technology, we provide end-to-end plastic mold injection molding solutions, from initial design consultation and mold fabrication to high-volume production and assembly. Our engineering team specializes in Design for Manufacturability (DfM) to optimize your part designs for performance, cost, and quality before tooling begins.

We offer a range of tooling options, including rapid aluminum molds for prototyping and hardened steel molds for full production, allowing you to scale efficiently. With our modern facilities, rigorous quality control, and expertise in processing both standard and high-performance engineering plastics, we are equipped to be your trusted manufacturing partner.

Considering injection molding for your next project? Contact Yigu Technology today for a comprehensive project review and quotation. Let us help you navigate the advantages and implement solutions for the challenges, ensuring a successful manufacturing outcome.