What is Short Shot Injection Molding?

Short Shot Injection Molding is a phenomenon in the injection molding process where the plastic melt fails to completely fill the mold cavity. In a perfect injection molding scenario, the molten plastic is injected into the mold under high pressure, filling every nook and cranny of the cavity. Once cooled and solidified, the resulting plastic part precisely replicates the shape of the mold. However, in the case of short shot injection molding, this process goes awry.

Imagine a mold designed to create a plastic toy car. During injection molding, if there is a short shot, instead of a fully - formed toy car, you might end up with a car body that is missing parts like the roof, wheels, or the front grille. This is because the plastic material did not reach all areas of the mold cavity.

The consequences of short shot injection molding are significant. For product quality, it leads to defective parts that are either unusable or require costly rework. In a production line for manufacturing plastic medical components, a short shot can render the components non - compliant with medical standards, leading to product recalls and damage to the manufacturer's reputation. In terms of production efficiency, short shot occurrences waste raw materials, time, and energy. Each short shot product means that the resources invested in that production cycle, from the plastic pellets to the machine operation time, are essentially wasted, and the production line has to be halted to remove the defective part and potentially adjust the injection molding parameters.

Impact of Short Shot Injection Molding

Product Defects

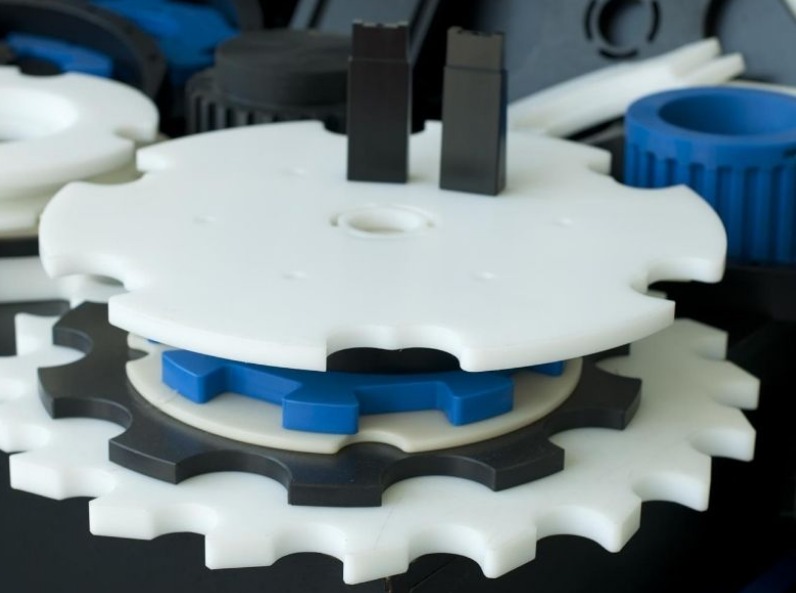

Short shot injection molding can lead to a plethora of product defects. One of the most obvious is (Dimensional Deviation). When the plastic does not fully fill the mold, the resulting part will not have the correct dimensions. For example, in the production of plastic gears, a short shot can cause the teeth of the gear to be incomplete or of the wrong size. This not only affects the appearance of the product but also its functionality. If the gear is used in a mechanical device, the incorrect dimensions can lead to improper meshing with other gears, resulting in increased wear and tear, noise, and even mechanical failure.

(Surface Incompleteness) is another common defect. The mold cavity has intricate details and surfaces that the plastic is supposed to replicate. With a short shot, areas of the part may be missing, have a rough surface, or lack fine features. In the manufacturing of plastic toy figures, short shots can cause the faces to be missing details like eyes, noses, or mouths, making the toys unappealing to consumers.

According to a study by a leading injection molding research institute, in a production run of 10,000 plastic parts, when short shots occurred due to improper injection pressure settings, the defect rate for products with dimensional deviation was as high as 15%, and for surface incompleteness, it was around 12%. These defective products often have to be discarded or undergo costly rework processes, increasing production costs significantly.

Production Inefficiency

The impact of short shot injection molding on production efficiency is substantial. (Increased Scrap Rate) is a direct consequence. Each short shot product is essentially a waste of raw materials, energy, and machine time. In a typical injection molding factory, the cost of raw materials for each part can range from a few cents to several dollars, depending on the type of plastic and the complexity of the part. If the scrap rate due to short shots is 10% in a production batch of 1000 parts, and the average raw material cost per part is \(0.5, the factory loses \)50 just on raw materials for that batch.

(Prolonged Production Cycle) is another issue. When a short shot occurs, the production line has to be halted to remove the defective part, analyze the cause, and make adjustments to the injection molding parameters. This downtime can range from a few minutes to several hours, depending on the complexity of the problem. For instance, if a production cycle for a single part without issues is 5 minutes, and on average, there are 3 short shot occurrences per hour, with each short shot causing a 10 - minute disruption, the effective production cycle per part increases to approximately 8 minutes. This significant slowdown in production can lead to missed delivery deadlines and a loss of customer satisfaction.

How to Avoid Short Shot Injection Molding

Optimize Material Selection

Selecting the right plastic material is crucial in preventing short shot injection molding. Different plastics have varying levels of fluidity, which directly impacts how well they can flow into the mold cavity. For example, materials like polyethylene (PE) and polypropylene (PP) generally have good fluidity. A study on injection molding of small plastic containers showed that when using a low - viscosity grade of PP, the short shot rate decreased from 20% to 5% compared to using a higher - viscosity material.

When choosing a material, consider the (Melt Flow Rate, MFR). MFR is a measure of the ease of flow of a thermoplastic polymer melt under specified conditions of temperature, load, piston diameter, and piston travel time. A higher MFR value indicates better flowability. For complex molds with long flow paths or thin - walled sections, materials with a relatively high MFR should be selected. For instance, in the production of thin - walled plastic cups, a material with an MFR of 15 - 20 g/10min might be more suitable than one with an MFR of 5 - 10 g/10min. Additionally, check the material's moisture content. Moisture in the plastic can cause gas formation during injection, leading to short shots. Materials like nylon (PA) are hygroscopic and need to be properly dried before injection. PA6, for example, should be dried to a moisture content of less than 0.1% to ensure smooth injection.

Adjust Injection Parameters

Proper adjustment of injection parameters is essential. (Injection Pressure) is the force that pushes the molten plastic into the mold cavity. As a general rule, increasing the injection pressure can help the plastic reach all parts of the mold. However, it should be increased gradually. In a case where a plastic housing was experiencing short shots, increasing the injection pressure from 80 MPa to 100 MPa in 5 - MPa increments solved the problem. But be cautious, as excessive pressure can lead to issues like flash (thin excess material around the part) and damaged molds.

(Injection Speed) also plays a significant role. A slow injection speed can cause the plastic to cool down prematurely, increasing its viscosity and making it difficult to fill the mold. For a thin - walled plastic part with a wall thickness of 1 - 2 mm, an injection speed of 50 - 80 mm/s might be optimal. If the speed is too high, it can cause air to be trapped in the mold, leading to voids or short shots.

(Temperature) is another critical parameter. The melt temperature affects the fluidity of the plastic. Each plastic material has a recommended processing temperature range. For example, the processing temperature range for polycarbonate (PC) is typically 280 - 320°C. If the melt temperature is too low, the plastic will be too viscous to flow properly, resulting in short shots.

The following graph shows how changes in injection pressure, speed, and temperature can affect the filling percentage of the mold cavity:

| Parameter | Low Setting | Medium Setting | High Setting |

| Injection Pressure | 60 MPa, 30% filling | 80 MPa, 60% filling | 100 MPa, 95% filling |

| Injection Speed (mm/s) | 30, 40% filling | 60, 70% filling | 90, 90% filling |

| Melt Temperature (°C) | 240 (for a material with a range of 260 - 300°C), 50% filling | 280, 80% filling | 300, 95% filling |

Improve Venting Design

Mold venting is often overlooked but is crucial for preventing short shots. When the plastic is injected into the mold, the air inside the cavity needs to escape. If it cannot, the trapped air creates a high - pressure zone that prevents the plastic from filling the mold completely.

One way to improve venting is by (Opening Vent Grooves). These grooves are typically located on the mold's parting surface. The depth and width of the vent grooves depend on the plastic material. For example, for a general - purpose plastic like ABS, the vent groove depth can be set between 0.02 - 0.04 mm and the width between 5 - 10 mm.

Another option is to use (Permeable Steel). Permeable steel has tiny pores that allow air to escape while preventing the plastic from flowing through. In a mold for manufacturing small, complex plastic parts, the use of permeable steel in the areas prone to short shots reduced the short shot rate from 15% to 3%.

The comparison of the filling rate before and after improving the venting design is as follows:

| Condition | Filling Rate Before Venting Improvement | Filling Rate After Venting Improvement |

| A complex mold with a small cavity | 70% | 95% |

Conduct Mold Flow Analysis

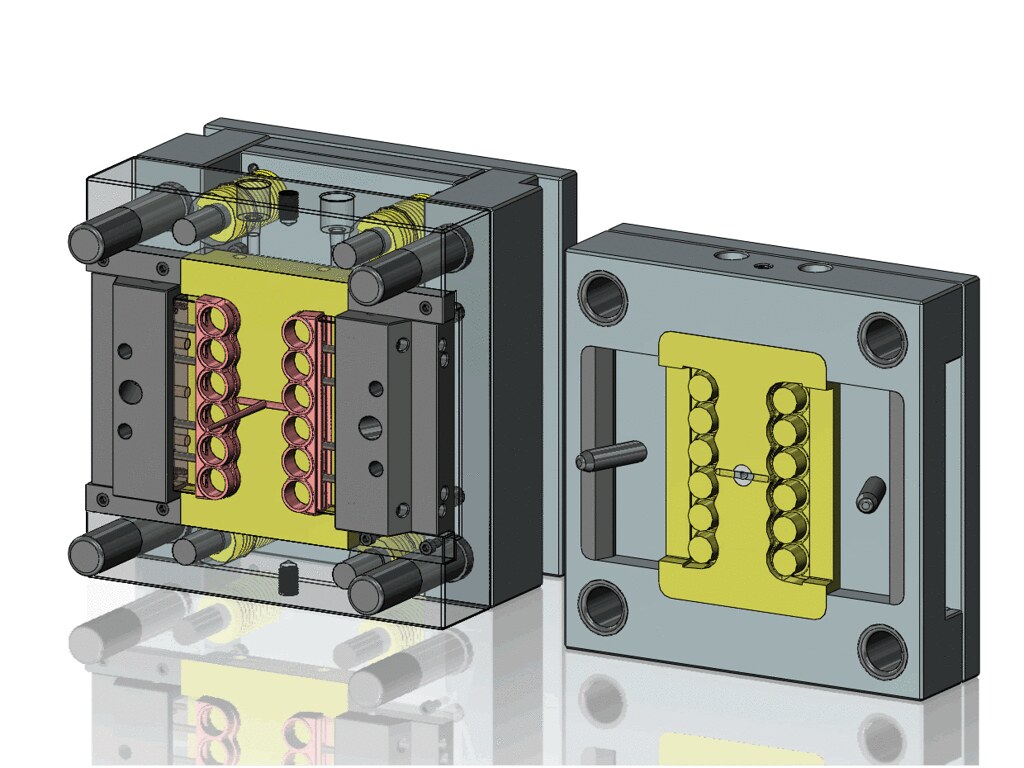

Mold flow analysis is a powerful tool for predicting and preventing short shot injection molding. It uses computer - aided engineering (CAE) software to simulate the injection molding process. By inputting parameters such as the mold geometry, material properties, and injection process conditions, the software can show how the plastic will flow inside the mold.

For example, in the design of a large - scale plastic automotive component, mold flow analysis was conducted. The initial analysis showed that there were areas in the mold cavity that were likely to experience short shots due to the complex geometry and long flow paths. Based on the analysis results, the designers adjusted the gate location and size, as well as the injection parameters. After the adjustments, the actual injection molding process had a short shot rate of less than 1%, compared to an estimated 20% without the mold flow analysis.

Mold flow analysis can also help in optimizing the cooling system, reducing cycle times, and predicting potential defects other than short shots, such as warping and sink marks. It provides valuable insights that can save time and costs in the production process by identifying and solving problems before actual production begins.

Yigu Technology's View

As a non - standard plastic metal products custom supplier, Yigu Technology has encountered numerous challenges related to short shot injection molding in our production process. One of the most common issues we faced was with a complex plastic component for an industrial device. The initial design of the mold had improper venting, and we were using a relatively high - viscosity plastic material. This combination led to a high short shot rate, sometimes as high as 20% in early production runs.

To address this, our engineering team first focused on improving the venting system. We redesigned the vent grooves, increasing their depth and width slightly based on the material's characteristics. Additionally, we optimized the injection parameters, gradually increasing the injection pressure by about 15% and adjusting the injection speed to ensure the plastic flowed smoothly. We also worked closely with our material suppliers to find a more suitable plastic grade with better flowability without sacrificing the product's mechanical properties. Through these efforts, we managed to reduce the short shot rate to less than 5%, significantly improving production efficiency and product quality.

FAQ

What are the common signs of short shot injection molding?

Common signs include visible unfilled areas on the product, where parts of the mold cavity remain empty. There may be sharp, distinct boundaries between the filled and unfilled sections. For example, in a plastic container, you might notice a smooth, filled bottom but a rough, unfinished - looking top edge that didn't receive enough plastic. Another sign is a lack of fine details. If the mold has intricate features like small holes or grooves, in the case of short shot, these details may be absent or only partially formed.

Can improper material drying lead to short shot?

Yes, improper material drying can lead to short shot. When plastic materials are not dried properly, the moisture within them turns into steam during the high - temperature injection process. This steam creates gas pockets and reduces the plastic's fluidity. For hygroscopic materials such as nylon, if they have a high moisture content, the steam generated can disrupt the smooth flow of the plastic into the mold cavity. The gas pockets act as barriers, preventing the plastic from reaching all areas of the mold, resulting in short shots.

How often should I check and maintain my injection molding machine to prevent short shot?

For optimal performance and to prevent short shot, it is recommended to conduct daily visual inspections. Check for any signs of wear and tear, leaks in the hydraulic or heating systems, and ensure that all moving parts are functioning smoothly. Weekly maintenance should involve a more in - depth check, including cleaning the machine, inspecting the screws and barrels for any signs of damage or excessive wear, and verifying the accuracy of the temperature and pressure sensors. Monthly maintenance could include more comprehensive checks such as lubricating all moving parts, checking the alignment of the mold plates, and testing the injection system's performance. Regular maintenance helps to keep the machine in top - working condition, ensuring consistent injection parameters and reducing the likelihood of issues that can cause short shots.