What is Parting Line Injection Molding?

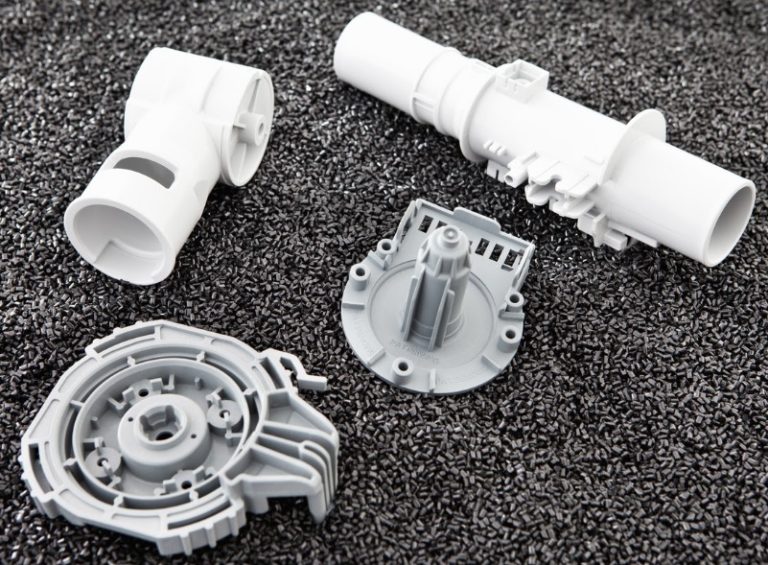

Parting line injection molding is a fundamental process in the plastic manufacturing industry. At its core, it involves injecting molten plastic into a mold cavity. Once the plastic cools and solidifies, it takes on the shape of the mold, creating a plastic product with specific dimensions and features.

The parting line is a crucial element in this process. It is the seam or boundary where the two halves of the mold meet. When the mold is closed during injection, the molten plastic fills the cavity through this parting line area. After cooling, the mold opens along the parting line, allowing the newly formed plastic part to be ejected. This line is not just a simple seam; it impacts the overall quality, appearance, and functionality of the final product. For example, in the production of a plastic toy, the parting line needs to be carefully designed. If it's not well - positioned, it could create a visible and rough seam on the toy's surface, affecting its aesthetic appeal. In more complex products like automotive interior components, an improper parting line can lead to issues with fit and finish, potentially causing problems during assembly or even compromising the structural integrity in some cases.

In injection molding, the parting line also plays a role in the flow of the molten plastic. It serves as the entry point for the plastic to fill the mold cavity evenly. The design of the parting line, including its shape, location, and the size of the channels through which the plastic flows, can influence factors such as the speed of filling, the distribution of material, and the formation of any potential defects like air pockets or uneven thickness. A well - designed parting line ensures that the plastic fills all the intricate details of the mold cavity without any issues, resulting in a high - quality and consistent product.

The Key Components and Their Functions

Mold Structure

The mold is a fundamental component in parting line injection molding, consisting of two main parts: the fixed mold (also known as the stationary mold) and the moving mold (or the ejector mold). The fixed mold is attached to the stationary platen of the injection molding machine, while the moving mold is connected to the movable platen.

When the injection molding process begins, the two halves of the mold close together. The parting line is the plane where these two mold halves meet. This line is crucial as it determines how the mold opens and closes. For example, in a simple plastic cup production, the parting line is usually located around the middle of the cup's height. When the mold closes, the molten plastic is injected into the cavity through channels that are designed along or near the parting line. As the plastic cools and solidifies, the mold opens along the parting line, and the newly formed plastic cup can be ejected.

The design of the mold cavity, which is the space where the plastic takes shape, is also closely related to the parting line. The shape and size of the cavity are precisely engineered to create the desired product. The parting line must be carefully positioned to ensure that the plastic flows evenly into all parts of the cavity. If the parting line is not well - designed, it can lead to issues such as incomplete filling of the mold, uneven wall thickness in the final product, or difficulty in ejecting the part. For instance, if the parting line has a sharp edge or an irregular shape in the area where the plastic enters the cavity, it can disrupt the flow of the molten plastic, causing defects like air traps or short shots (where the plastic does not fully fill the mold).

Injection System

The injection system is responsible for melting the plastic raw materials and injecting them into the mold cavity. It typically starts with plastic pellets being fed into the hopper of the injection molding machine. These pellets then enter the barrel, where they are heated. The heating is usually achieved through electric heater bands wrapped around the barrel.

Inside the barrel, a screw or a plunger is used to move the plastic. In a screw - type injection system (the most common type), as the screw rotates, it not only conveys the plastic pellets forward but also shears and compresses them. This shearing action generates frictional heat, which, combined with the heat from the heater bands, melts the plastic pellets into a viscous, molten state.

Once the plastic is fully melted, the screw or plunger applies high pressure to push the molten plastic through the nozzle and into the mold cavity. The pressure and speed at which the plastic is injected are critical factors. High injection pressure can help the plastic fill complex mold cavities more easily, especially those with thin walls or intricate details. However, if the pressure is too high, it can cause problems such as flash (where the plastic leaks out between the mold halves along the parting line), excessive internal stress in the product, or even damage to the mold. On the other hand, low injection pressure may result in incomplete filling of the mold.

The injection speed also plays a role. A fast injection speed can reduce the cycle time and improve production efficiency. But it can also cause issues like air entrapment or jetting (where the plastic squirts unevenly into the mold cavity). For example, when molding a small, detailed plastic component like a miniature gear, precise control of injection pressure and speed is essential. A proper balance ensures that the molten plastic fills all the tiny teeth of the gear accurately without causing any defects.

Cooling System

The cooling system is vital for the injection molding process as it enables the molten plastic to solidify into the desired shape. It works by circulating a cooling medium, usually water, through channels that are strategically placed within the mold. As the hot, molten plastic fills the mold cavity, heat is transferred from the plastic to the mold walls. The cooling medium flowing through the channels absorbs this heat, effectively cooling down the plastic.

Cooling time is a significant factor in the overall cycle time of injection molding. If the cooling time is too short, the plastic may not have sufficient time to solidify properly, leading to a product with poor dimensional stability, warping, or even sticking to the mold. Conversely, if the cooling time is too long, it can reduce production efficiency. For example, in the production of large plastic containers, a longer cooling time may be required due to their larger mass and volume.

Uneven cooling can cause serious product defects. When different parts of the plastic cool at different rates, internal stresses are created within the product. These stresses can lead to warping, where the product does not maintain its intended shape. For example, in a flat plastic panel, if one side cools faster than the other, the panel will warp, making it unusable for its intended application. To prevent uneven cooling, mold designers carefully plan the layout of the cooling channels. They ensure that the cooling medium flows evenly around the entire mold cavity, maintaining a consistent temperature distribution. This may involve using baffles or manifolds within the cooling channels to direct the flow of the cooling medium and achieve more uniform cooling.

The Injection Molding Process Step by Step

Plastic Material Preparation

Before the injection molding process begins, proper plastic material preparation is essential. Most plastic raw materials come in pellet form. One crucial step is drying the plastic pellets. Moisture in the plastic can cause significant problems during molding. For example, when water - containing plastic is injected into the mold, the heat during the process turns the moisture into steam. This steam can create bubbles or voids within the final product, weakening its structural integrity and degrading its appearance.

Commonly used plastic materials in injection molding include:

- ABS (Acrylonitrile - Butadiene - Styrene): ABS is a popular choice due to its excellent balance of properties. It has high impact resistance, good dimensional stability, and is easy to process. In the automotive industry, it is often used for interior components such as dashboard panels. Its ability to withstand impacts makes it suitable for parts that may be subject to accidental knocks. In the electronics industry, ABS is used for device housings, providing protection to the internal components while also being aesthetically pleasing due to its smooth finish and ease of coloring.

- PP (Polypropylene): PP is known for its high chemical resistance, good heat resistance, and low density. It is widely used in the packaging industry, for example, in the production of food containers. Its chemical resistance ensures that it does not react with the contents of the containers, while its heat resistance allows for applications such as microwave - safe food containers. In the manufacturing of household items like plastic chairs, PP's low density makes the products lightweight and easy to move around, yet its strength still provides stability.

- PE (Polyethylene): PE comes in different grades, such as HDPE (High - Density Polyethylene) and LDPE (Low - Density Polyethylene). HDPE is rigid and has high strength, making it suitable for applications like water pipes. Its durability and resistance to corrosion ensure a long - lasting performance in supplying water. LDPE, on the other hand, is more flexible and is often used for making plastic bags and films. Its flexibility allows for easy handling and conformability to various shapes.

Filling the Mold Cavity

Once the plastic material is prepared, it enters the mold cavity. The injection molding machine uses a screw or plunger to push the molten plastic through a nozzle and into the mold. This process occurs at high pressure to ensure that the plastic can quickly and completely fill the mold cavity, even if it has complex shapes and thin walls.

The filling speed, pressure, and temperature all play crucial roles in the filling process:

- Filling Speed: A fast filling speed can reduce the cycle time, which is beneficial for high - volume production. However, if the speed is too high, it can cause air to be trapped inside the mold cavity. This trapped air can create voids or burn marks on the product surface. For example, when molding a small, intricate plastic component with many small holes or cavities, a high - speed injection may force the air into these small spaces, resulting in defects. On the other hand, a slow filling speed may lead to incomplete filling, especially in areas of the mold with complex geometries.

- Injection Pressure: Sufficient injection pressure is necessary to push the molten plastic into every part of the mold cavity. Low pressure can result in short - shots, where the plastic does not fully fill the mold. This is often seen in large - scale or complex - shaped molds. High injection pressure, while it can ensure complete filling, also increases the risk of flash. Flash occurs when the plastic leaks out between the mold halves along the parting line due to excessive pressure.

- Temperature: The temperature of the molten plastic affects its viscosity. A higher temperature makes the plastic more fluid, which can improve its flowability and filling ability. But if the temperature is too high, it can cause thermal degradation of the plastic, changing its properties and potentially leading to discoloration or a reduction in mechanical strength. For example, some heat - sensitive plastics like certain grades of PVC (Polyvinyl Chloride) need to be carefully temperature - controlled during injection to avoid degradation.

Cooling and Solidification

After the mold cavity is filled with molten plastic, the cooling and solidification stage begins. During this stage, the hot plastic inside the mold loses heat to the surrounding mold walls. The cooling system, which typically circulates a cooling medium like water through channels in the mold, accelerates this heat - transfer process.

The cooling time is a critical factor:

- Impact on Product Quality: If the cooling time is too short, the plastic may not have enough time to solidify properly. This can lead to a product with poor dimensional stability, where the shape of the product may change after it is removed from the mold. Warping is a common issue caused by insufficient cooling. For example, in the production of a flat plastic panel, if one side cools faster than the other, the panel will warp, making it unsuitable for its intended use.

- Effect on Production Efficiency: On the other hand, an overly long cooling time can reduce production efficiency. Each additional second of cooling time adds up over the course of mass production. For instance, in a high - volume production line of plastic toys, if the cooling time can be reduced by just 5 seconds per toy, it can significantly increase the number of toys produced per day.

The temperature of the cooling medium also matters. A lower - temperature cooling medium can speed up the cooling process, but it may also cause uneven cooling if not properly distributed. This is why mold designers carefully plan the layout of the cooling channels to ensure uniform cooling.

Ejection and Finishing

Once the plastic has cooled and solidified into the desired shape, it is time to eject the product from the mold. The injection molding machine uses an ejection system, which typically consists of ejector pins or plates. These ejectors push the molded product out of the mold cavity.

After ejection, the product often undergoes post - processing steps:

- Removing Flash: Flash, the thin excess plastic that forms along the parting line, needs to be removed. This can be done manually using tools like knives or scissors for small - scale production. In larger - scale operations, machines such as trimming presses may be used to efficiently remove the flash.

- (Sanding): Sanding is used to smooth out any rough surfaces on the product. This can improve the aesthetic appearance of the product and also remove any small imperfections left from the molding process.

- (Painting): Painting can add color and a protective layer to the product. It can also enhance the product's visual appeal. For example, plastic toys are often painted to make them more attractive to children, and automotive plastic parts may be painted to match the color of the vehicle's body.

Yigu Technology's Perspective

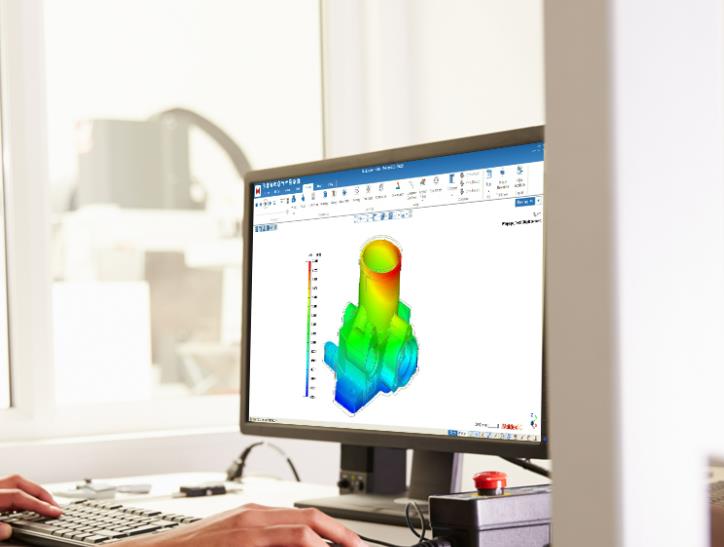

As a non - standard plastic metal products custom Supplier, Yigu Technology has in - depth experience in parting line injection molding. Our advanced mold design capabilities enable us to precisely position the parting line, minimizing its impact on product appearance and functionality. For example, we use state - of - the - art CAD/CAM software to simulate the plastic flow during the injection process, ensuring an optimal parting line design.

Quality control is at the heart of our production process. We have strict inspection procedures at every stage, from mold manufacturing to the final product. This ensures that each custom - made product meets the highest quality standards. Whether it's a small, intricate component or a large - scale product, we are committed to providing our customers with high - quality, customized solutions that meet their specific requirements.