How Does Injection Molding Craft Brilliant Products?

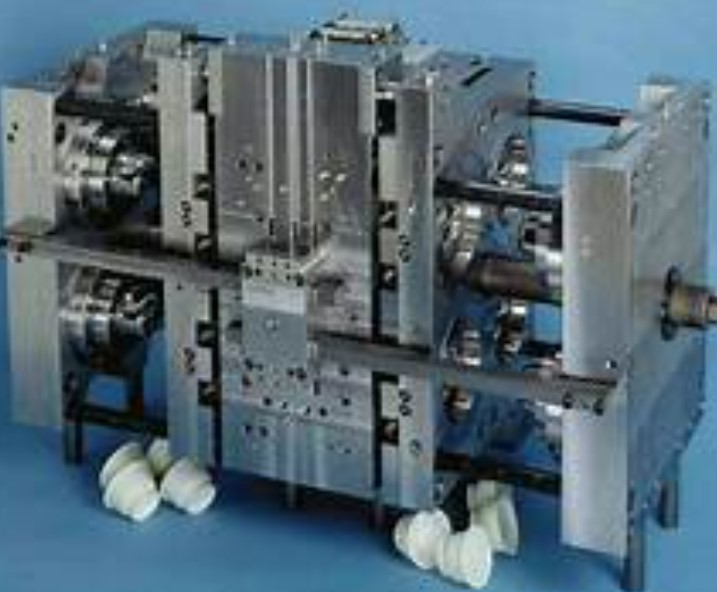

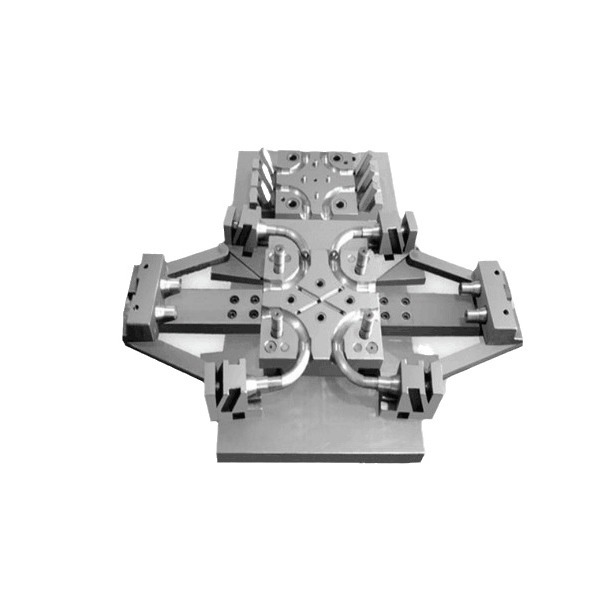

Introduction Injection molding is a widely used manufacturing process that has revolutionized the production of plastic products. It involves injecting molten material, typically plastic, into a mold cavity under high pressure. Once the material cools and solidifies within the mold, it takes on the precise shape of the cavity, resulting in a finished product. This […]