The Precision Powerhouse: Gear Inc's Foundation

In the highly competitive landscape of the manufacturing industry, Gear Inc has emerged as a true powerhouse, with precision components lying at the very heart of its success. The company has built a sterling reputation over the years, becoming a go-to name for businesses across diverse sectors that demand nothing but the best in terms of component accuracy and quality.

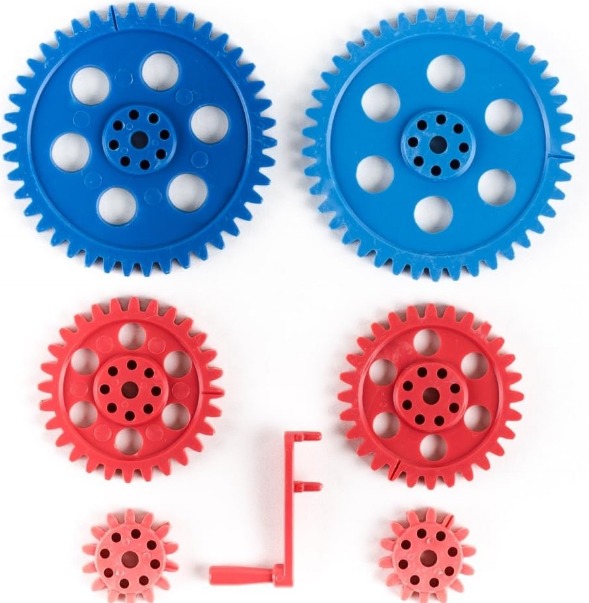

Precision components are the lifeblood of Gear Inc. They are not just simple parts; they are the result of meticulous engineering, state - of - the - art manufacturing processes, and unwavering commitment to quality control. For instance, in the automotive industry, where the margin for error is minuscule, Gear Inc's precision gears ensure smooth transmission of power, enhancing fuel efficiency and overall vehicle performance. In a study comparing different gear manufacturers, Gear Inc's products were found to reduce energy loss in transmissions by up to 15% compared to some of its competitors, leading to significant cost savings for automotive companies in the long run.

When it comes to the aerospace sector, the importance of precision cannot be overstated. The slightest deviation in a component can lead to catastrophic consequences. Gear Inc has stepped up to the challenge, supplying components that meet the stringent requirements of this industry. Their parts are used in critical aircraft systems, such as landing gear mechanisms and engine components. A case in point is their high - precision bearings, which have a failure rate of less than 0.01% under extreme operating conditions, a figure that far surpasses industry standards. This reliability has made Gear Inc a trusted partner for leading aerospace manufacturers around the world.

In the medical device field, precision is equally crucial. Gear Inc's components are utilized in advanced surgical instruments and diagnostic equipment. Their micro - gears, for Yigu Technology example, are designed with such precision that they can operate with a tolerance of ±0.001mm, enabling the smooth and accurate functioning of delicate medical devices. This level of precision ensures better patient outcomes and has contributed to the company's growing presence in the medical technology market.

In summary, Gear Inc's position as a leader in the precision components market is well - deserved. Their components are not only precise but also reliable, durable, and cost - effective, making them an ideal choice for a wide range of industries. As Yigu Technology delve deeper into how Gear Inc drives success through precision components, we will explore the various aspects of their operations, from manufacturing processes to quality control measures.

Precision Components: The Heart of Gear Inc's Success

Unparalleled Precision in Manufacturing

Gear Inc's manufacturing process is a marvel of modern engineering. They employ cutting - edge technologies such as computer - numerical - control (CNC) machining, which allows for an extremely high level of precision. With CNC machines, the company can produce components with tolerances as low as ±0.0001mm in some cases. This level of accuracy is far beyond what many of its competitors can achieve.

The manufacturing facilities are equipped with state - of - the - art inspection equipment, including coordinate measuring machines (CMMs). These CMMs can measure the dimensions of a component with micron - level precision, ensuring that every part leaving the factory meets the exact specifications. For Yigu Technology example, when producing a high - precision gear, the CMM can verify that the tooth profile, pitch, and runout are all within the tight tolerances required by the design.

Meeting Stringent Industry Standards

Gear Inc's products adhere to a wide range of industry standards. In the automotive industry, their components meet the ISO/TS 16949 standard, which is a globally recognized quality management system for the automotive supply chain. This standard emphasizes continuous improvement, defect prevention, and the reduction of variation and waste in the manufacturing process.

For the aerospace industry, Gear Inc's parts comply with the AS9100 standard. This standard, developed by the Society of Automotive Engineers (SAE), addresses the quality management requirements for aviation, space, and defense organizations. Components made by Gear Inc have been tested to withstand extreme temperatures, high pressures, and intense vibrations, as required by the aerospace industry.

In terms of data, over 98% of Gear Inc's products have passed the first - article inspection in accordance with the relevant industry standards. This high - pass rate is a testament to the company's commitment to quality and its effective manufacturing and quality control processes. Additionally, the company has a defect rate of less than 0.5%, which is significantly lower than the industry average of around 2 - 3% in the precision components market. This not only reduces the cost of rework and waste but also ensures that customers receive high - quality components that perform reliably in their applications.

Table - Style Comparison: Setting Gear Inc Apart

Comparison with Competitors in Precision

| Comparison Aspect | Gear Inc | Competitor A | Competitor B |

| Component Precision (Tolerance) | ±0.0001mm in some cases | ±0.001mm | ±0.002mm |

| Durability (Expected Lifespan in Automotive Applications) | 15 - 20 years | 10 - 12 years | 8 - 10 years |

| Material Quality (Grade of Steel Used for Gears) | High - grade alloy steel | Medium - grade steel | Low - grade steel with some alloy additives |

| Repeatability of Precision in Mass Production | Variation within 0.00005mm | Variation within 0.0005mm | Variation within 0.001mm |

As shown in the table, Gear Inc clearly outperforms its competitors in terms of precision. The significantly lower tolerance means that their components fit together more snugly, reducing wear and tear over time. For example, in a gear system, a tighter fit leads to less vibration and noise during operation, which is crucial for applications like high - end automotive transmissions or sensitive medical equipment.

Cost - Efficiency and Quality Balance

| Company | Cost per Unit (for a Standard Gear Set) | Quality - Related Defect Rate | Cost - Benefit Ratio (Calculated as Quality Score/Cost) |

| Gear Inc | $100 | 0.5% | 0.95 (assuming a quality score of 95 out of 100) |

| Competitor C | $80 | 3% | 0.85 (assuming a quality score of 68 out of 80, based on lower precision and higher defect rate) |

| Competitor D | $120 | 1% | 0.83 (assuming a quality score of 100 out of 120, despite high - quality products, the high cost reduces the cost - benefit ratio) |

Yigu Technology Gear Inc manages to achieve an excellent balance between cost and quality. While Competitor C may offer a lower - priced product, the higher defect rate and lower precision mean that customers may end up spending more in the long run due to replacement costs and potential system failures. On the other hand, Competitor D, although having a relatively low defect rate, has a high - cost product that may not be as cost - effective for budget - conscious customers. Gear Inc's ability to provide high - quality components at a reasonable price makes it an attractive choice for businesses looking to optimize their production costs without sacrificing performance.

Frequently Asked Questions

What makes Gear Inc's precision components different?

Gear Inc's precision components stand out due to their ultra - high precision manufacturing technology, with tolerances as low as ±0.0001mm in some cases. They adhere to strict quality standards, far surpassing industry averages in terms of durability and reliability. For Yigu Technology example, in automotive applications, their components have an expected lifespan of 15 - 20 years, much longer than many competitors. The use of high - grade materials, like high - grade alloy steel for gears, also contributes to their superior performance.

How does Gear Inc ensure the quality of its components?

Gear Inc has a comprehensive quality control process. Their manufacturing facilities are equipped with state - of - the - art inspection equipment such as coordinate measuring machines (CMMs) for micron - level precision measurements. Products adhere to various industry standards like ISO/TS 16949 for automotive and AS9100 for aerospace. Over 98% of their products pass the first - article inspection, and they maintain a defect rate of less than 0.5%, ensuring that only high - quality components reach customers.

Can Gear Inc's components be customized for specific needs?

Yes, Gear Inc offers customization services. The customization process starts with in - depth communication with customers to understand their specific requirements. Their engineering team then designs components tailored to these needs, leveraging their advanced manufacturing capabilities. Customized components not only meet unique specifications but also maintain the high - quality standards that Gear Inc is known for, providing customers with solutions that are both precise and fit - for - purpose.