Plastic & Metal industry knowledge

Transfer the value information of rapid prototypes, mold and injection molding industry

A Comparison of Metal 3D Printing Methods

The world of metal 3D printing has grown from a simple tool for making prototypes into a complex system of specialized manufacturing technologies. For engineers and designers, choosing the right...

Mastering High-Quality Resin 3D Printing: A Guide to Creating Prototypes and Final Products

The discussion about resin 3D printing is changing. It has grown from a hobby tool for simple visual models into an advanced technology for professional prototyping and small-scale manufacturing. For...

A Guide to Standards and Best Practices for Industrial 3D Models

An industrial 3D model is much more than just a shape on a computer screen. It's a valuable digital copy of a real physical part. When these models aren't created...

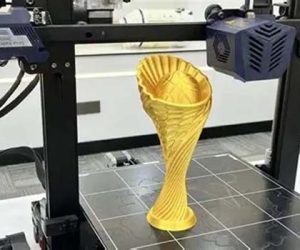

A Guide to 3D Printing Molds for Making Plastic Parts

The way we make molds is changing in a big way. For many years, companies have used CNC machines to cut molds from solid metal blocks. This method works well...

Ultrasonic-Assisted Milling for Hard Materials: A Complete Technical Guide

Regular milling has serious problems when cutting hard, breakable materials like advanced ceramics and fiber-reinforced composites. The process often creates very high cutting forces, destroys tools quickly, damages the material...

Understanding Internal Keyways and Splines with Broach Milling: A Beginner's Guide

What Is Broach Milling? Broach milling is a modern cutting process that uses a special cutting tool on a computer-controlled machine to create internal shapes like keyways and splines. It...

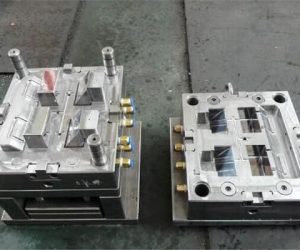

Precision Tooling with CNC for Mold Fabrication

In today's manufacturing world, molds are the bridge between digital designs and real, high-quality products. For industries where mistakes can be costly—like car manufacturing, medical equipment, and electronics—the quality of...

How Much Does Laser Cutting Sheet Cost? A Complete Guide

If you’re wondering about laser cutting sheet prices, the short answer is: they typically range from \(15 to \)150 per sheet, with additional laser cutting service costs of \(10 to...

What Are the Best Sheet Metal Solutions for Your Manufacturing Needs?

If you’re in manufacturing, construction, or any industry that relies on metal components, you’ve probably asked: What exactly are sheet metal solutions, and how do I choose the right ones...

How to Choose the Right Metal Working Company for Your Project?

If you’re asking this question, you’re likely in the middle of a project that needs professional metal fabrication, machining, or finishing—whether it’s for industrial equipment, custom parts, or architectural elements....

What You Need to Know About Auto Parts Service: A Complete Guide

If you’ve ever had a car break down or needed to replace a worn-out component, you’ve probably wondered: what exactly is auto parts service, and how do I make sure...

Turning Plastic: A Comprehensive Guide to Precision, Safety, and Sustainability

Imagine finishing a batch of acrylic parts only to notice a haze from poor ventilation—rendering them unfit for optical use. Or worse, a worker developing respiratory issues from inhaling ABS...

What You Need to Know About Custom Metal Laser Cutting for Your Project?

If you’re wondering whether custom metal laser cutting is the right choice for your project, or how to make the most of this technology, you’ve come to the right place....

What Can Custom Metal Fabricators Inc Do for Your Project?

If you’re wondering what custom metal fabricators inc brings to the table, the short answer is: they turn your unique metal ideas into tangible, high-quality products—whether you need a single...

Turning Plastic: Mastering the Art of Precision Machining for Polymers

Picture this: You’re machining a critical nylon component for a medical device, and halfway through the process, the part melts around the tool, ruining hours of work. Or maybe you’re...

Machining Accuracy: The Ultimate Guide to Achieving Precision in Manufacturing

Imagine a scenario where a medical device component is machined with a 0.01mm deviation from the required dimensions. That tiny error could render the device unsafe for use, leading to...

Mastering G Codes Machining: Solving Programming Challenges for Precision Manufacturing

Anyone who’s stared at a CNC machine screen, watching a tool carve the wrong path because of a misplaced G-code, knows the frustration. A single mistyped digit in a G01...

Large Machined Parts: Overcoming Challenges in Manufacturing and Applications

When it comes to large machined parts, manufacturers and engineers face a unique set of headaches. Imagine spending weeks on a massive steel component only to find it warps during...

Precision Advanced Machining: Technologies, Applications, Solutions for High-Tolerance Manufacturing

Imagine a medical device manufacturer struggling to machine a 0.1 mm diameter hole in a titanium implant with a tolerance of ±0.001 mm—any error could risk patient safety. Or an...

Aluminum CNC Projects: Techniques, Applications, and Solutions for Precision Results

Imagine a prototype shop spending days machining an aluminum bracket, only to find that chatter during milling left rough surfaces requiring expensive rework. Or an aerospace manufacturer struggling to keep...