If you’re wondering what additive manufacturing composites are and why they matter, let’s start with a clear answer: Additive manufacturing (AM), often called 3D printing, combined with composites (materials made of two or more distinct components) creates parts that are stronger, lighter, and more durable than traditional materials like metal or plastic alone. This technology lets you build complex shapes layer by layer using composite materials—think carbon fiber mixed with plastic or glass fiber with resin—opening up new possibilities for industries from aerospace to healthcare. Unlike traditional manufacturing, which often wastes material or limits design, AM composites let you make precise, custom parts with minimal waste. Now, let’s dive deeper into how this works, its key benefits, and where it’s making the biggest impact.

What Are Additive Manufacturing Composites?

To understand additive manufacturing composites, let’s break down the two terms first. Additive manufacturing is the process of building objects by adding layers of material (instead of cutting or shaping from a block, like subtractive manufacturing). Composites are materials made by combining two or more substances with different properties—for example, a strong “reinforcement” material (like carbon fiber or glass fiber) and a “matrix” material (like plastic resin or metal) that holds the reinforcement together. When you put them together, you get AM composites: parts made by 3D printing layers of these composite materials.

The magic of AM composites lies in their ability to combine the best of both worlds. The reinforcement (e.g., carbon fiber) adds strength and stiffness, while the matrix (e.g., thermoplastic resin) adds flexibility and ease of printing. This means you can create parts that are lighter than metal but just as strong—critical for industries where weight matters, like aerospace. For example, a carbon fiber-reinforced plastic (CFRP) part made via AM can be up to 50% lighter than a similar aluminum part, while still meeting strength requirements.

A real-world example of this is in the automotive industry. Ford has used additive manufacturing composites to make prototype parts for its F-150 pickup trucks. Instead of using heavy metal brackets, they 3D printed CFRP brackets that were 30% lighter and just as strong, helping improve the truck’s fuel efficiency during testing.

Key Types of Composite Materials Used in Additive Manufacturing

Not all AM composites are the same—they’re defined by the type of reinforcement and matrix used. Below are the most common types, along with their uses and benefits, organized in a table for clarity:

| Composite Type | Reinforcement Material | Matrix Material | Key Benefits | Common Applications |

| Carbon Fiber-Reinforced Polymers (CFRP) | Carbon fiber (short or continuous) | Thermoplastics (e.g., ABS, PLA) or thermosets | High strength-to-weight ratio, stiff | Aerospace parts, drone frames, sports equipment |

| Glass Fiber-Reinforced Polymers (GFRP) | Glass fiber | Thermoplastics or resins | Affordable, good impact resistance, corrosion-resistant | Automotive parts, marine components, consumer goods |

| Metal Matrix Composites (MMC) | Ceramic fibers (e.g., alumina) or metal particles | Metals (e.g., aluminum, titanium) | High temperature resistance, strong | Jet engine parts, industrial tooling |

| Natural Fiber-Reinforced Composites | Hemp, flax, or bamboo fiber | Biodegradable plastics | Eco-friendly, low cost, lightweight | Packaging, furniture, low-load consumer parts |

A notable case is Airbus, which uses continuous carbon fiber AM composites to make brackets for its A350 aircraft. By using continuous fibers (instead of short pieces), the brackets have uniform strength across the part—something hard to achieve with traditional manufacturing. This not only reduced the weight of each bracket by 40% but also cut production time from weeks to days.

Why Choose Additive Manufacturing Composites? Key Advantages

If you’re deciding whether to use AM composites for your project, here are the top benefits that make them stand out from traditional materials and manufacturing methods:

1. Superior Strength-to-Weight Ratio

The biggest draw of AM composites is their strength relative to their weight. For example, CFRP AM parts have a strength-to-weight ratio that’s 2x higher than aluminum and 5x higher than steel. This is a game-changer for industries like aerospace, where every pound saved reduces fuel costs. Boeing reports that using AM composites in its 787 Dreamliner reduced the aircraft’s overall weight by 15%, leading to 20% lower fuel consumption compared to older planes.

2. Design Freedom for Complex Shapes

Traditional manufacturing (like machining or molding) struggles with complex designs—think parts with internal channels, lattice structures, or organic shapes. AM composites let you print these shapes layer by layer, no extra tools needed. For instance, in healthcare, additive manufacturing composites are used to make custom hip implants with lattice structures that mimic bone. These implants are not only lighter but also let new bone grow into the lattice, improving long-term stability for patients. A study by the Journal of Biomedical Materials Research found that these composite implants have a 30% higher success rate than traditional metal implants.

3. Reduced Material Waste

Subtractive manufacturing (e.g., cutting a part from a metal block) can waste up to 90% of the original material. AM composites, by contrast, only use the material needed to build the part—waste is often less than 5%. This is not just cost-effective but also eco-friendly. For example, the furniture brand IKEA has tested natural fiber AM composites to make custom chair parts. By 3D printing only what’s needed, they cut material waste by 80% compared to making parts with traditional molding.

4. Faster Prototyping and Production

Creating a prototype with traditional methods can take weeks (e.g., making a mold for plastic parts). With AM composites, you can design a part in CAD software and print it in hours or days. This speeds up the design-test-improve cycle. A small drone company, DJI, used AM composites to prototype a new drone frame. Instead of waiting 4 weeks for a molded plastic frame, they printed a CFRP frame in 2 days, letting them test 5 design iterations in the time it would take for one traditional prototype.

Real-World Applications of Additive Manufacturing Composites

AM composites aren’t just a lab technology—they’re already transforming industries. Let’s look at three key sectors where they’re making a big difference, with specific examples:

Aerospace and Defense

Aerospace is one of the earliest adopters of additive manufacturing composites because weight and strength are critical. Lockheed Martin, for example, uses AM composites to make fuel tanks for its Orion spacecraft. The tanks are made of carbon fiber-reinforced thermoplastic, which is lightweight (reducing launch costs) and resistant to the extreme temperatures of space. Before AM, these tanks were made by joining multiple metal pieces, which added weight and risk of leaks. The AM composite tanks are 25% lighter and have 50% fewer parts, improving reliability.

Automotive

Car manufacturers use AM composites to make both prototype and production parts. Tesla, for instance, uses glass fiber-reinforced AM composites to make underbody shields for its Model Y. These shields protect the car’s battery from debris and are 10% lighter than traditional plastic shields. Since lighter cars use less energy, this helps extend the Model Y’s range by about 5 miles per charge. Additionally, AM lets Tesla produce the shields in small batches, which is useful for testing new designs without investing in expensive molds.

Healthcare

In healthcare, additive manufacturing composites are used to make custom medical devices. For example, 3D Systems makes dental crowns using a composite of ceramic fibers and resin. These crowns are printed to match the exact shape of a patient’s tooth (using a 3D scan) and are stronger than traditional porcelain crowns. They also take less time to make—instead of waiting 2 weeks for a lab to make a crown, dentists can print one in a few hours, letting patients get their crowns in a single visit. Another example is prosthetics: companies like Open Bionics use AM composites to make lightweight, durable prosthetic hands that cost a fraction of traditional metal prosthetics.

Challenges and How to Overcome Them in Additive Manufacturing Composites

While AM composites have many benefits, they’re not without challenges. Here are the most common issues and practical solutions to address them:

1. High Material Costs

Composite materials (especially carbon fiber) are more expensive than traditional plastics or metals. For example, a kilogram of carbon fiber-reinforced filament can cost \(50–\)100, compared to \(2–\)5 for standard PLA filament. Solution: For low-load parts, use glass fiber-reinforced composites (which cost 30–50% less than carbon fiber). For high-load parts, optimize the design to use less material—e.g., add lattice structures instead of solid sections. A study by the Additive Manufacturing Journal found that lattice designs can reduce material use by up to 60% without losing strength.

2. Inconsistent Part Quality

Sometimes, AM composite parts can have defects like air bubbles or uneven fiber distribution, which weakens the part. Solution: Use a 3D printer with a closed-loop system that monitors and adjusts the printing process in real time. For example, Stratasys’ FDM printers for composites have sensors that check the flow of filament and adjust the speed or temperature to prevent defects. Additionally, post-processing (like heating the part in an oven) can help eliminate air bubbles and improve fiber bonding.

3. Limited Printer Compatibility

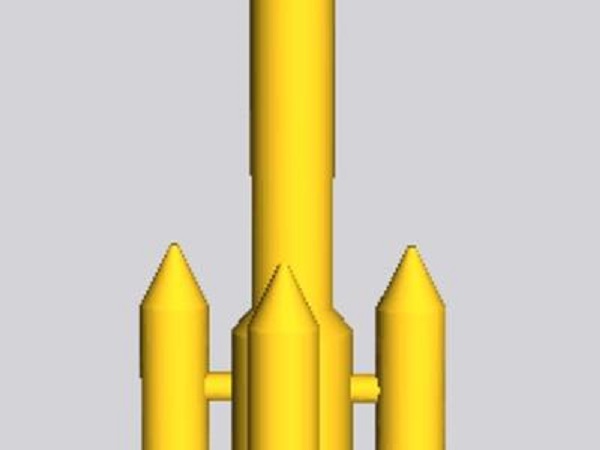

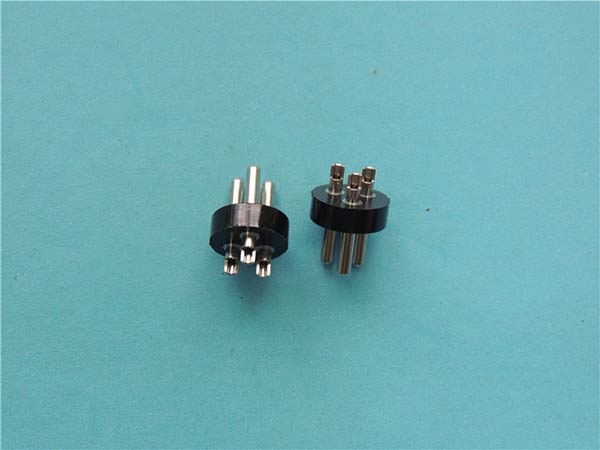

Not all 3D printers can handle composite materials—reinforcement fibers can wear down the printer’s nozzle or jam the extruder. Solution: Invest in a printer designed for composites, which has hardened nozzles (e.g., made of steel or ruby) that resist wear. For example, the Markforged Onyx Pro printer uses a hardened steel nozzle and a specialized extruder that can handle continuous carbon fiber. If you already have a standard printer, you can upgrade it with a composite-compatible nozzle (costing \(20–\)50) to print short-fiber composites.

Future Trends in Additive Manufacturing Composites

The future of additive manufacturing composites is exciting, with new technologies and applications on the horizon. Here are three trends to watch:

1. More Sustainable Composite Materials

As industries focus on sustainability, we’ll see more eco-friendly AM composites. For example, companies like BioCellection are developing composites made from recycled plastic and natural fibers (like hemp). These composites are biodegradable and use waste materials, reducing their environmental impact. A 2024 report by Grand View Research predicts that the market for sustainable AM composites will grow by 25% annually over the next 5 years.

2. Multi-Material and Multi-Functional Printing

Soon, you’ll be able to print parts that combine multiple composite materials in one process—e.g., a part with a strong carbon fiber section for load-bearing and a flexible glass fiber section for movement. This will let you make more complex parts, like robot arms that have both rigid and flexible components. Researchers at MIT are already testing this technology, using a 3D printer that can switch between different composite filaments mid-print.

3. Larger-Scale Production

Right now, AM composites are often used for small parts or prototypes. But as printers get bigger and faster, we’ll see them used for larger parts—like airplane wings or wind turbine blades. For example, GE Renewable Energy is developing a 3D printer that can print 10-meter-long wind turbine blades using glass fiber composites. This would cut the production time of blades from months to weeks and reduce waste by 70%.

Yigu Technology’s Perspective on Additive Manufacturing Composites

At Yigu Technology, we believe additive manufacturing composites are set to become a cornerstone of modern manufacturing, especially as industries prioritize efficiency, sustainability, and customization. From our work with clients in automotive and consumer electronics, we’ve seen firsthand how AM composites solve pain points like heavy part weight and slow prototyping. For example, we helped a client reduce the weight of their electronic device casing by 25% using glass fiber-reinforced AM composites, while keeping production costs in check by optimizing material use. We also see huge potential in sustainable composites—by combining recycled materials with AM, businesses can reduce their carbon footprint without sacrificing performance. As the technology matures, we expect to see more small and medium-sized businesses adopting AM composites, thanks to lower-cost printers and more accessible materials.

FAQ About Additive Manufacturing Composites

1. Are additive manufacturing composites more expensive than traditional materials?

Yes, composite materials (like carbon fiber) are often more expensive upfront, but they can save money long-term. For example, lighter parts reduce fuel costs in aerospace, and less material waste cuts production costs. For low-budget projects, glass fiber composites are a more affordable alternative to carbon fiber.

2. Can additive manufacturing composites be used for high-temperature applications?

Yes—metal matrix composites (MMCs) are designed for high temperatures. For example, MMC parts made with titanium matrix and ceramic fibers can withstand temperatures up to 800°C, making them ideal for jet engine parts or industrial ovens.

3. How long does it take to print a part with additive manufacturing composites?

It depends on the size and complexity of the part. Small parts (like a drone bracket) can take a few hours, while larger parts (like a automotive component) can take 1–2 days. This is still faster than traditional manufacturing, which can take weeks for prototypes.

4. Are additive manufacturing composite parts recyclable?

Some are. Thermoplastic-based composites (like CFRP with ABS matrix) can be melted and reused. Natural fiber composites are also biodegradable. However, thermoset-based composites are harder to recycle—research is ongoing to develop better recycling methods for these materials.

5. Do I need special training to use a 3D printer for composites?

Basic training is helpful, especially to avoid issues like nozzle wear or fiber jams. Most composite printers come with user guides, and many manufacturers offer online tutorials. For beginners, starting with short-fiber composites (easier to print) before moving to continuous fibers is a good idea.