Understanding Insert Molding

What is Insert Molding?

Insert molding is a specialized manufacturing process that combines the properties of different materials to create a single, integrated component. It involves placing a pre - formed insert, which can be made of various materials such as metal, glass, ceramics, or even another type of plastic, into a mold cavity. Then, molten plastic is injected into the mold, flowing around the insert. As the plastic cools and solidifies, it bonds firmly with the insert, resulting in a composite part with enhanced functionality.

For example, in the production of electronic devices, metal inserts are often used in plastic housings. The metal provides better conductivity for grounding purposes, while the plastic offers insulation and a lightweight, easy - to - mold structure. In automotive applications, inserts can be used to reinforce plastic components, adding strength and durability. Common metal materials for inserts include brass, which is popular due to its excellent corrosion resistance, easy machinability, and moderate cost. Aluminum is also used for its lightweight properties, and steel for its high strength.

The Process of Insert Molding

- Insert Preparation:

- Inspection and Cleaning: Before placing the insert into the mold, it must be carefully inspected for any defects such as cracks, burrs, or incorrect dimensions. Cleaning the insert is also crucial to remove any dirt, oil, or debris that could affect the bonding between the insert and the plastic. For example, metal inserts may be cleaned using solvents or by ultrasonic cleaning methods.

- Pre - treatment (if necessary): Some inserts, especially metal ones, may require pre - treatment. This could involve processes like surface roughening to improve the adhesion with the plastic. For instance, a metal insert might be sand - blasted to create a rough surface texture that allows the plastic to bond more effectively. In the case of some materials, like certain types of plastics used as inserts, they may need to be dried to remove moisture, as water can cause defects during the injection molding process.

- Mold installation:

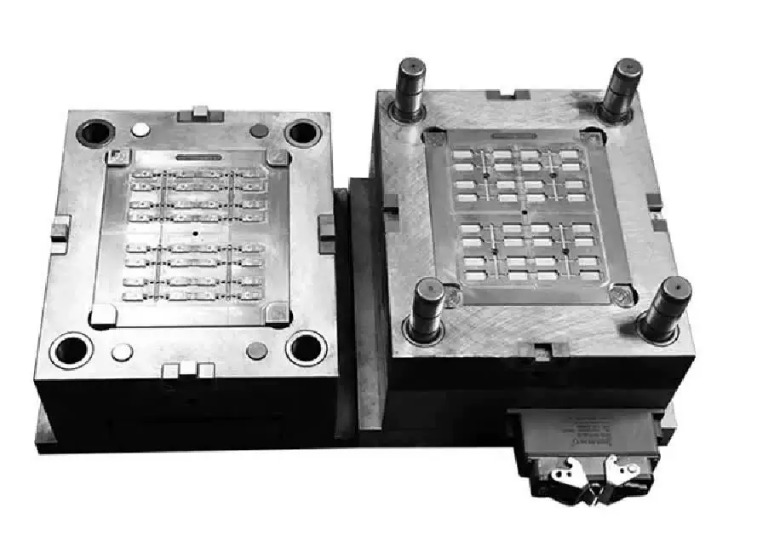

- Mold Selection and Inspection: The mold is a critical component of the insert molding process. It must be designed to accommodate the specific insert and the desired plastic part shape. Before installation, the mold is inspected for any signs of wear, damage, or improper alignment. All moving parts, such as slides and ejector pins, are checked to ensure smooth operation.

- Mounting the Mold: The mold is then mounted onto the injection molding machine. This process requires careful alignment to ensure that the mold is properly centered and secured. Specialized equipment like hoists or cranes may be used to lift and position the mold. Once in place, it is fastened securely to the machine using bolts or clamps.

- Injection molding:

- Plastic Material Selection and Preparation: The appropriate plastic material is chosen based on the requirements of the final product, such as its mechanical properties, chemical resistance, and aesthetic appearance. The plastic is usually in the form of pellets and may need to be dried to remove moisture. It is then fed into the injection molding machine's hopper.

- Injection: The plastic pellets are melted in the machine's heating barrel and then injected into the mold cavity at high pressure. The pressure and temperature during injection are carefully controlled. For example, the injection pressure can range from 50 - 200 MPa, depending on the complexity of the part and the type of plastic used. The temperature is set according to the melting point of the plastic, typically in the range of 150 - 300°C for common plastics like polyethylene and polypropylene.

- Filling and Packing: As the molten plastic fills the mold cavity, it flows around the insert. After the cavity is filled, additional pressure is applied (packing pressure) to ensure that the plastic is fully packed into all the corners of the mold and around the insert, compensating for any shrinkage during cooling.

- Cooling demolding:

- Cooling: Once the plastic is injected and packed, the mold is cooled to solidify the plastic. Cooling can be achieved through various methods, such as water - cooled channels within the mold. The cooling time is carefully determined to ensure that the plastic has fully solidified without over - cooling, which could cause stress in the part. For a small - to - medium - sized plastic part, the cooling time may range from 10 - 60 seconds.

- Ejection: After cooling, the mold opens, and the finished part with the embedded insert is ejected from the mold using ejector pins or other ejection mechanisms. The part is then removed from the machine, and any excess plastic, such as flash or runner systems, may be trimmed off.

Key Factors to Consider When Choosing an Insert Molding Company

Experience and Expertise

Experience is the cornerstone of a reliable insert molding company. A company with years of dedicated focus on insert molding is more likely to handle various challenges efficiently. For example, a company that has been in the insert molding business for over 15 years has likely encountered a wide range of insert materials, plastic types, and design complexities. They have a wealth of knowledge on how different materials interact during the molding process, which is crucial for producing high - quality parts.

Moreover, a large portfolio of successful cases across multiple industries is a strong indicator of expertise. In the automotive industry, they might have produced components like gearshift knobs with metal inserts for enhanced grip and durability. For the electronics sector, they could have created plastic housings with metal inserts for better heat dissipation and electromagnetic shielding. These real - world examples demonstrate their ability to adapt to the specific requirements of different industries.

Quality Assurance

Quality assurance is non - negotiable when choosing an insert molding company. A top - tier company will have a strict quality - inspection process in place. This typically involves multiple checkpoints throughout the production cycle. Before the injection molding process, inserts are inspected for any defects, and the molds are thoroughly examined for proper alignment and functionality.

Advanced inspection equipment is also a sign of a quality - conscious company. High - precision coordinate measuring machines (CMMs) can measure the dimensions of the finished parts with an accuracy of up to ±0.001 mm, ensuring that they meet the tightest tolerances. In addition, the company should adhere to international quality standards such as ISO 9001. This standard ensures that the company has a well - defined quality management system in place, covering everything from raw material sourcing to the final product delivery.

Production Capacity

Production capacity is another crucial factor. A company with a large number of high - quality injection molding machines can handle larger orders. For instance, a company equipped with 50 injection molding machines, ranging from small - tonnage machines suitable for small - scale production to large - tonnage ones for bigger parts, has more flexibility.

Monthly production capacity is an important metric. A company that can produce 100,000 insert - molded parts per month can easily meet the demands of medium - to - large - scale manufacturers. This high production capacity also means that they can handle sudden spikes in demand without compromising on quality or delivery time. Whether it's a small - batch prototype order or a large - scale production run, a company with sufficient production capacity can provide a reliable service.

Cost - Effectiveness

Cost - effectiveness is a key consideration for any business. When evaluating an insert molding company, it's important to look at the overall cost structure. Mold costs can vary significantly depending on the complexity of the design. A simple mold for a basic insert - molded part might cost around \(5,000, while a highly complex mold with intricate features could cost upwards of \)50,000.

Injection molding costs are also a factor. On average, the injection molding cost per part can range from \(0.10 for a small, simple part to \)1.00 or more for a larger, more complex one. However, companies that offer volume discounts can provide significant cost savings. For example, a company might offer a 10% discount on orders of 10,000 parts or more. Comparing these costs with other insert molding companies in the market can help you make an informed decision. A detailed cost - comparison table can be a useful tool:

| Company | Mold Cost (Simple Part) | Injection Molding Cost per Part (Small, Simple) | Volume Discount Threshold | Discount Percentage |

| Company A | $5,000 | $0.12 | 5,000 | 5% |

| Company B | $4,500 | $0.10 | 10,000 | 10% |

| Company C | $5,500 | $0.15 | 8,000 | 8% |

Customization Services

Customization services are essential for many businesses. A good insert molding company should be able to design molds and products according to the unique requirements of its clients. This could involve creating a custom - shaped insert to fit a specific product design or developing a unique plastic formulation to meet certain performance criteria.

For example, a client in the medical device industry might need an insert - molded part with biocompatible materials and very precise dimensions for a new surgical instrument. The insert molding company should have the expertise to design and manufacture the part to these exact specifications. A successful customization case could be a company that designed and produced a specialized insert - molded component for a leading aerospace company. The component had to withstand extreme temperatures and high mechanical stress, and the insert molding company was able to develop a solution that met all the requirements.

Technology and Equipment

The use of advanced technology and equipment can significantly improve the quality and efficiency of insert molding. Automation is becoming increasingly important in the industry. Automated insert - loading systems can place inserts into the molds with high precision and speed, reducing the risk of human error and increasing production rates. For example, a robotic arm can load inserts into a mold in a matter of seconds, compared to the minutes it might take a human operator.

High - precision mold - making equipment is also crucial. Computer - numerical - control (CNC) machines can create molds with extremely tight tolerances, ensuring that the final products are of the highest quality. Additionally, advanced injection molding technologies such as gas - assisted injection molding can be used to produce parts with complex geometries and better internal structures. Gas - assisted injection molding involves injecting gas into the molten plastic during the molding process, which can help to reduce internal stresses and improve the surface finish of the part.

Yigu Technology's View

Yigu Technology, as a non - standard plastic metal products custom Supplier, deeply understands the significance of insert molding. With years of experience in custom - manufacturing various plastic metal products, we have a unique perspective on this field.

We place great emphasis on product quality. From the selection of high - quality raw materials, including different types of plastics and metals for inserts, to the strict control of the manufacturing process, every step is carefully monitored. Our team of experienced engineers is constantly innovating in design. We work closely with clients, starting from the initial concept stage. By understanding their specific needs, such as the functionality requirements of the final product, the environmental conditions it will be exposed to, and any aesthetic considerations, we can provide customized insert molding solutions.

For example, when a client had a unique design for a consumer electronics product that required a specific shape of metal insert for better signal reception within a plastic housing, we used our expertise to design a mold and develop a molding process that met all their requirements. This close cooperation ensures that the final insert - molded products not only meet but exceed the clients' expectations.

FAQ

What is the minimum order quantity for insert molding?

The minimum order quantity (MOQ) for insert molding varies from company to company. It is often influenced by factors such as mold costs, production processes, and the complexity of the parts. For simple insert - molded parts, some companies may have a minimum order quantity as low as 1,000 - 5,000 units. This is because the mold cost can be more easily spread out over a relatively small number of parts in cases where the production process is straightforward. However, for more complex parts or those that require special molds, the MOQ can be significantly higher, sometimes ranging from 10,000 - 50,000 units. For example, if a part has intricate insert designs and the mold is very expensive to produce, the company may require a larger order quantity to make the production cost - effective.

How long does the insert molding process usually take?

The insert molding process time depends on several factors. The mold design phase can take anywhere from 2 - 6 weeks, especially for complex molds that require precise engineering and CAD - CAM design. Once the mold is ready, the injection molding part of the process for a single cycle can be relatively quick, usually ranging from 10 - 60 seconds for small - to - medium - sized parts. But for large - scale production runs, the overall time will be affected by the number of parts to be produced. After the injection molding, post - processing steps such as trimming excess plastic, quality inspection, and packaging can add another 1 - 3 days for a typical batch of parts. In general, for a small - batch order of 1,000 - 5,000 parts, the entire production process, from the start of mold design to final product delivery, can take 4 - 8 weeks.

What materials can be used for inserts in insert molding?

A variety of materials can be used for inserts in insert molding. Metals are commonly used, such as copper, which offers good conductivity and corrosion resistance, making it suitable for applications in electrical components. Aluminum is another popular choice due to its lightweight nature and relatively high strength - to - weight ratio, often used in automotive and aerospace applications. Steel inserts are used when high strength and durability are required, like in heavy - duty machinery parts. Plastics can also be used as inserts, especially when the goal is to combine different types of plastics with distinct properties, such as using a rigid plastic insert in a more flexible plastic matrix. Ceramics are sometimes used for their high - temperature resistance and chemical stability. For example, in some industrial applications where the final product needs to withstand extreme heat or harsh chemical environments, ceramic inserts can be a great option.