Launching a new plastic component is a pivotal step for any product developer, engineer, or business. Finding the right partner for Custom Injection Molding is not just about finding a machine shop; it's about selecting a collaborative engineering and manufacturing ally. A misstep can lead to costly delays, poor part quality, and project failure. This guide moves beyond simple checklists, providing a strategic framework for evaluating potential partners. We will walk you through defining your core requirements, scrutinizing technical capabilities, and navigating the hidden complexities of mold design, timelines, and costs. By the end, you'll know precisely how to identify a custom injection molder that can reliably transform your vision into a high-quality, manufacturable, and commercially viable product.

What Is Custom Injection Molding?

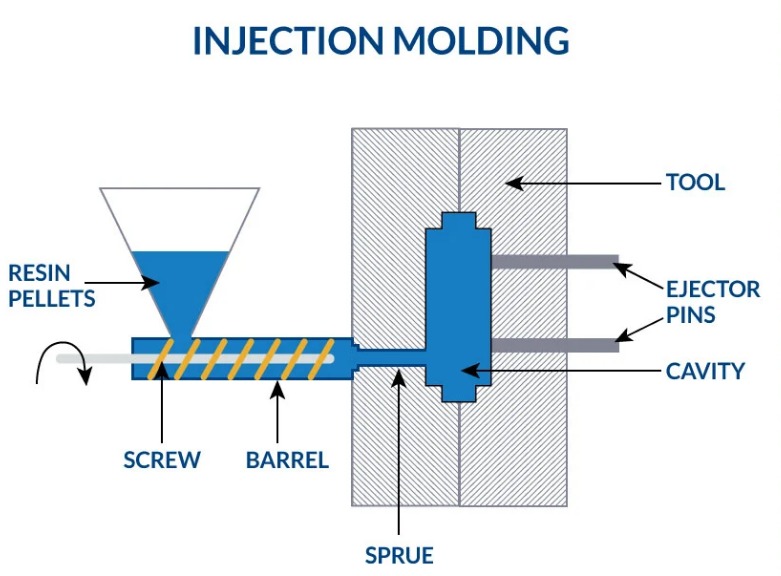

Custom Injection Molding is a manufacturing service where a molder designs, prototypes, and produces unique plastic parts to a client's exact specifications. Unlike standard part sourcing, it involves a tailored, collaborative process from concept to mass production. The service provider doesn't just operate machines; they offer integrated expertise in part design optimization (DFM), mold engineering, material science, and production validation. The outcome is a proprietary component, tooled with a custom mold, and produced under controlled conditions. This is essential for anything from a specialized medical device housing to a unique consumer electronics bezel.

Which Project Requirements Must Be Defined First?

Clarity internally prevents confusion externally. Before contacting a single vendor, crystallize these five pillars:

- Part Function & Critical Dimensions: What does the part do? What are the non-negotiable tolerances (e.g., ±0.05mm for a gear)? What are cosmetic "Class A" surfaces?

- Annual Volume & Production Lifespan: Is this a 500-unit prototype run, 50,000 units per year, or 5 million? Volume dictates the mold's robustness (e.g., aluminum vs. hardened steel) and the pricing model.

- Material Performance Needs: List required properties: strength, flexibility, heat resistance, biocompatibility, UV stability, flammability rating (e.g., UL94 V-0). Don't just name a resin; define the requirements.

- Regulatory & Compliance Standards: Medical (ISO 13485), Automotive (IATF 16949), Food Contact (FDA, NSF), or Consumer Safety (CPSC, REACH). This will immediately filter potential molders.

- Budget & Timeline Constraints: Have realistic ranges for NRE (Non-Recurring Engineering/Tooling) and piece-part cost. Know your "need-by" date for first samples and production launch.

How to Evaluate a Molder’s Technical Capabilities?

Look for evidence of problem-solving, not just machine lists. Ask these pointed questions:

- "Can we review a DFM report for a similar part?" This reveals their proactive engineering approach to prevent molding issues like sink, warp, or short shots.

- "What is your process for validating a new mold?" A strong answer includes: First Article Inspection (FAI) with a detailed report (often using a PPAP - Production Part Approval Process format), capability studies (Cp/Cpk) on critical dimensions, and a mold qualification run at production speeds.

- "What advanced technologies do you employ for complex parts?" Listen for: Mold flow analysis software (e.g., Moldflow), scientific molding practices, automated in-process measurement, and experience with multi-material, overmolding, or micro-molding if relevant.

- Request a facility tour (virtual or in-person). Observe organization, machine condition, and quality labs. A molder producing medical parts should have a clean, controlled environment separate from their industrial work.

What Quality Certifications Should You Demand?

Certifications are a baseline, not a guarantee of excellence, but their absence is a major red flag.

- ISO 9001: The fundamental quality management system. Essential for any serious molder.

- IATF 16949: The automotive industry standard. Demands rigorous process control and traceability.

- ISO 13485: For medical device manufacturing. Focuses on risk management, documentation, and sterilization compatibility.

- AS9100: The aerospace equivalent, emphasizing product safety and reliability.

Pro Tip: Ask how their certification is implemented. For instance, "How does your ISO 13485 system manage material traceability from resin pellet to shipped part?" The answer should be specific and involve lot numbers and controlled documentation.

How to Assess Material Selection Support?

A true partner guides you beyond the data sheet. They should:

- Challenge Your Presumptions: If you specify expensive PEEK, they might ask if a high-temperature PPS or filled nylon could meet requirements at 30% lower cost.

- Discuss Supply Chain: Recommend materials with stable, multi-source supply chains to avoid future shortages.

- Consider Processability: Advise on how a material's shrinkage rate or hygroscopic nature (e.g., nylon) will affect the mold design and drying requirements.

- Provide Physical Samples: Offer molded test coupons or samples from past projects in the materials under consideration so you can feel and test them.

Case in Point: A client insisted on ABS for an outdoor enclosure. Our engineering team performed UV and weatherability testing on samples, demonstrating severe yellowing. We presented data comparing ABS to UV-stabilized Polycarbonate/ABS blend and ASA, leading to a better, longer-lasting product choice.

Mold Design: In-House or Outsourced—Which Is Better?

This is critical. Insist on in-house mold design expertise. Here’s why:

| Aspect | In-House Mold Design Team | Outsourced Mold Design |

|---|---|---|

| Communication | Seamless, daily collaboration with production engineers. | Slow, prone to miscommunication via emails/phone. |

| Iteration Speed | Fast. Design changes can be evaluated and modified in hours. | Delayed by external schedules and revision fees. |

| Problem Solving | The designer is on the shop floor during mold tryout, seeing issues firsthand. | The designer is removed from the physical tryout and troubleshooting. |

| Accountability | Single point of responsibility for the complete process: design, build, and production. | Blame-shifting can occur between the molder and the external designer. |

A molder who outsources core design relinquishes control over the most critical determinant of part quality, cost, and lead time.

How to Compare Lead-Time Promises Realistically?

Beware of unrealistically short quotes. A professional lead time breaks down into sequential, realistic phases:

- DFM & Final Quote: 1-2 weeks.

- Mold Design: 2-4 weeks.

- Mold Manufacturing (Steel Cutting, EDM, Polishing, Assembly): This is the largest variable. A simple single-cavity aluminum mold: 4-6 weeks. A multi-cavity, hardened steel mold with complex actions: 12-20+ weeks.

- Mold Tryout, Sampling, and Revisions: 2-4 weeks (allowing for at least one round of tweaks).

Ask: "What is your current shop capacity for new mold builds?" and "Can you provide a Gantt chart with milestones?" A detailed schedule shows professionalism and awareness.

What Hidden Costs Appear in Custom Quotes?

The lowest initial quote can be the most expensive. Scrutinize for these often-overlooked items:

- Mold Maintenance & Repair: Who pays for routine maintenance or unexpected damage? Is there an annual storage fee for the mold?

- Engineering Change Orders (ECOs): What is the cost structure for part design changes after the mold has been built?

- Sample Costs: Are initial T1 samples included, or billed separately?

- Packaging: Is standard packaging included, or is custom packaging quoted as an add-on?

- Minimum Order Quantities (MOQs): Are there MOQs for production runs that are higher than your need?

- Payment Terms for Tooling: Is it 100% upfront, or staged payments tied to milestones (e.g., 30% on order, 40% on design approval, 30% on first sample approval)?

Conclusion

Selecting a custom injection molding partner is a strategic decision with long-term implications. It requires moving beyond price-per-part comparisons to a holistic evaluation of technical depth, collaborative culture, and transparent processes. The ideal partner acts as an extension of your team, combining design for manufacturability expertise, in-house mold mastery, rigorous quality systems, and proactive communication to de-risk your project. By methodically defining your needs and vetting potential suppliers against the criteria outlined here, you secure not just a vendor, but a pathway to a successful, scalable, and high-quality product launch.

FAQ on Custom Injection Molding Services

What is the typical cost range for a custom injection mold?

Mold costs vary enormously, from $3,000 for a simple prototype aluminum mold to $100,000+ for a high-cavity, production-grade steel mold with complex slides and actions. Key cost drivers are mold size, material (aluminum vs. steel), number of cavities, surface finish, and tolerances.

How many design revisions are usually included?

A reputable molder will typically include one to two rounds of minor revisions (e.g., gate size adjustment, venting, minor dimensional tweaks) after the initial T1 sample run. Major design changes that require significant re-machining of the mold core or cavity are nearly always billed as an Engineering Change Order (ECO).

What file format do I need to provide for a quote?

A 3D CAD file in STEP or IGES format is the industry standard for quoting and DFM. Provide a clean, finalized model. Also include a 2D drawing PDF with critical dimensions, tolerances, and material specifications.

Can you use my existing mold?

Often, yes—this is called "mold hosting" or "production-only" service. However, the molder will require a full inspection and trial run to ensure the mold is in good condition, compatible with their presses, and capable of producing parts to their quality standards. Modifications may be needed.

What is the difference between a prototype and a production mold?

Prototype molds are often made from softer aluminum, have fewer cavities (1), and are designed for lower volumes (100-1,000 parts). They are faster and cheaper to build. Production molds are made from hardened tool steels, have multiple cavities for efficiency, include robust cooling and ejection systems, and are built to withstand millions of cycles.

Contact Yigu technology for custom manufacturing.

At Yigu Technology, we embody the partner-centric approach detailed in this guide. We integrate full in-house mold design and manufacturing with scientific injection molding production under one roof, governed by ISO 9001 and IATF 16949 certified quality systems. Our engineers don't just take orders; they collaborate from the first sketch to provide actionable DFM feedback, material science guidance, and transparent project management.

We specialize in turning complex challenges into manufacturable, high-performance parts. If you're looking for a custom injection molding partner committed to your project's success with clarity, expertise, and reliability, your search ends here.

Contact Yigu Technology today for a confidential consultation and a detailed, no-obligation project analysis.