Introduction to Articulated 3D Printing

Articulated 3D printing is a transformative advancement in additive manufacturing, enabling the production of intricate, movable designs with interconnected parts in a single printing process. This innovation eliminates assembly, allowing for seamless creation of objects with joints and flexibility. It has vast applications across industries, including robotics, medical devices, automotive, aerospace, and consumer products, delivering bespoke designs with unprecedented precision and efficiency.

Definition and Principles

What is Articulated 3D Printing?

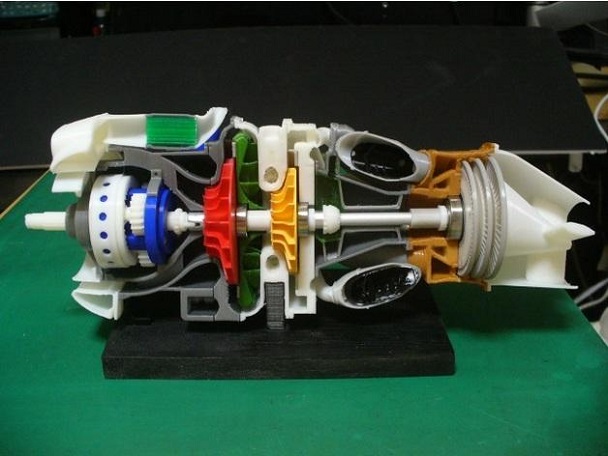

Articulated 3D printing refers to the additive manufacturing of objects with integrated mobility. Unlike traditional 3D printing, which typically produces static items, this technique incorporates dynamic components like joints, hinges, and pivots. These elements are fully functional upon completion, providing mechanical freedom and flexibility without additional assembly.

How It Works

The process of articulated 3D printing begins with the design of a 3D model, often using specialized CAD software. The object’s geometry includes precise arrangements of rigid and flexible sections or embedded mechanisms for movement. Advanced printing technologies then execute the design using:

- Multi-Material Printing: Combining different materials, such as rigid polymers and flexible elastomers, for varied mechanical properties.

- Embedded Mechanisms: Printing around prefabricated components like hinges to ensure integrated motion.

- Variable Density Printing: Adjusting material density within a single object for optimized rigidity or flexibility.

- Support-Free Printing: Specialized methods that allow movable parts to print in place without needing removable supports.

Historical Development

Evolution of Articulated 3D Printing

- Early Attempts (1980s - 1990s): Initial 3D printing experiments focused on creating static shapes. Adding movable parts required separate assembly.

- Multi-Material Printing (2000s): The advent of multi-material printers allowed the integration of rigid and flexible components within one object.

- Enhanced Design Software (2010s): Tools for simulating and refining movable designs emerged, enabling precise articulation.

- Variable Density and Support-Free Printing (2020s): Breakthroughs in density control and elimination of support structures further enhanced articulated designs.

Benefits and Applications

Key Advantages

- Seamless Integration: Articulated designs eliminate assembly, improving efficiency and reducing manufacturing complexity.

- Customization: Tailored designs for specific needs, such as patient-specific medical implants or bespoke robotics components.

- Precision: High accuracy ensures tight tolerances and reliable functionality of movable parts.

- Cost and Time Efficiency: Reduction in material waste and assembly time results in faster, more cost-effective production.

Applications Across Industries

Robotics

Articulated 3D printing enables lightweight, functional robotic arms, grippers, and actuators. Designs can mimic natural joint movement, improving robot dexterity and adaptability.

Medical Devices

Custom prosthetics, orthotics, and implants benefit from articulated printing’s ability to fit and function precisely with the human body. Patient-specific devices can enhance comfort and recovery.

Automotive

The automotive industry uses articulated 3D printing for prototyping and creating end-use parts like adaptive dashboards and lightweight mechanical assemblies.

Aerospace

In aerospace, articulated components reduce weight and increase durability for extreme environments, aiding in fuel efficiency and operational reliability.

Consumer Goods

From toys with moving parts to wearable tech with integrated hinges, articulated printing offers creative solutions for personalized products.

Customizability in Design

Articulated 3D printing supports unique and user-specific designs, addressing challenges traditional manufacturing cannot.

- Tailored Solutions: Adaptation to individual needs, such as ergonomic tools or adaptive devices for people with disabilities.

- Personalized Medical Products: Prosthetics and surgical guides tailored to exact anatomical requirements.

- Bespoke Consumer Goods: Highly customizable items like accessories, footwear, or gadgets designed to individual specifications.

Efficiency in Manufacturing

Enhanced Workflow

- Assembly-Free Production: Movable objects emerge fully functional, eliminating post-production steps.

- Material Efficiency: Additive methods minimize waste by using only the necessary material.

- Rapid Prototyping: Faster creation of functional prototypes accelerates product development cycles.

Technical Aspects

Materials and Processes

- Thermoplastics: Commonly used for durable, rigid structures.

- Flexible Materials: Elastomers like TPU for bendable, hinge-like components.

- Biocompatible Materials: Medical-grade materials for patient-specific applications.

- Composite Materials: Reinforced polymers for enhanced strength and lightweight designs.

Key Techniques

- Slicing Software: Precise control of layer-by-layer printing for interlocking mechanisms.

- Variable Density Control: Creating gradients in material properties for customized flexibility or rigidity.

- Support-Free Design: Printing movable parts without the need for supports that require post-removal.

Challenges and Limitations

- Material Constraints: Limited availability of materials that balance rigidity and flexibility.

- Design Complexity: High expertise required for creating reliable articulated models.

- Cost of Equipment: Initial investment in advanced printers can be prohibitive for small businesses.

- Adoption Barriers: Limited infrastructure and familiarity slow widespread implementation.

Future Outlook

Advancing the Frontiers

- Improved Materials: Development of new, high-performance polymers and composites.

- Expanded Accessibility: Affordable multi-material printers for broader adoption.

- Software Integration: Enhanced AI-driven design tools for automated articulation planning.

Industry Evolution

Articulated 3D printing is poised to disrupt traditional manufacturing, enabling companies to innovate with bespoke, efficient designs while fostering sustainable practices through reduced waste and energy consumption.

Conclusion

Articulated 3D printing transforms the landscape of design and manufacturing, bridging the gap between complexity and efficiency. With applications spanning from robotics to medical devices, its ability to produce integrated, customizable, and functional components heralds a new era of innovation. As technology and materials continue to evolve, articulated 3D printing is set to redefine the limits of what can be designed, built, and brought to market.