Choosing a Plastic Injection OEM Partner is a strategic decision that goes far beyond a simple supplier transaction. This partner will become the guardian of your product's quality, the steward of your brand's reputation, and a critical link in your supply chain resilience. A misstep can lead to costly delays, public recalls, and eroded market trust. For brands, startups, and established companies alike, selecting the right partner requires a systematic, discerning evaluation of capabilities that are often invisible in a standard RFQ. This guide provides a rigorous framework to help you identify a reliable Plastic Injection OEM Partner—one that combines technical excellence with a culture of quality and a commitment to partnership for the long term.

What Defines Reliable Plastic Injection OEM Partner?

Reliability in an OEM context is a multi-dimensional trait, evidenced by consistent performance over years and across challenges. A reliable partner demonstrates:

- Proactive Problem-Solving: They don't just execute orders; they anticipate issues in design, material, or process and present solutions before they become your problem.

- Transparent Communication: They operate with open books on project status, challenges, and costs. There are no surprises. They have formal channels for escalation protocols and regular business reviews.

- Financial and Operational Stability: They have the resources to invest in new technology, weather market fluctuations, and scale with your business. A check of their D&B rating and years in business is prudent.

- Cultural Alignment: Their business values—around quality, ethics, and partnership—align with yours. They act as a true extension of your team.

Which Certifications (IATF 16949, ISO 13485, etc.) Should You Verify?

Certifications are audited proof of a systemic approach to quality, not just a plaque on the wall. The required certification is dictated by your industry.

- IATF 16949: This is the non-negotiable global standard for automotive. It mandates rigorous process control, risk management, and continuous improvement. Any partner serving auto or heavy vehicle must have this.

- ISO 13485: The essential standard for medical device manufacturing. It focuses on risk management, traceability, and validation processes critical for patient safety. A partner without this cannot legally produce most medical components.

- ISO 9001: The baseline quality management system. While important, for regulated industries, it is merely a foundation upon which industry-specific standards are built.

- Others: AS9100 for aerospace, ISO 14001 for environmental management. Always request the certificate scope to confirm injection molding is explicitly included.

How to Evaluate Technical Capabilities and Press Range?

The machine park must align with your part's size, material, and volume needs.

- Press Tonnage and Platen Size: Ensure they have a range (e.g., 80 to 2000 tons) to accommodate your parts both now and in the future. Ask about clamp force accuracy and injection unit screw technology (e.g., dedicated screws for PVC vs. general-purpose).

- Specialized Technologies: Do they have capabilities you may need?

- Multi-Material/Overmolding: For soft-touch grips or sealed assemblies.

- Micro-molding: For tiny, high-precision medical parts.

- Gas-Assist or MuCell Foam Molding: for large, rigid parts with reduced weight and sink.

- Automation Integration: Look for evidence of robotic sprue pickers, vision inspection systems, and automated packaging lines. This is critical for consistency, labor cost control, and lights-out manufacturing potential.

What Quality Systems Ensure Zero Defect Supply?

A "zero defect" mindset is built on prevention, not sorting.

- Advanced Process Control: Do they practice scientific molding? Key indicators are the use of mold cavity pressure sensors and viscosity control to monitor the process in real-time, ensuring each shot is identical.

- Statistical Process Control (SPC): They should be collecting real-time data on critical dimensions and using control charts (Cp/Cpk) to predict and prevent deviations, not just react to them.

- Comprehensive Inspection: They must have in-house CMMs (Coordinate Measuring Machines), optical comparators, and functional test rigs. Ask about their First Article Inspection (FAI) and Production Part Approval Process (PPAP) rigor.

- Traceability: Systems must provide full lot traceability from resin pellet to shipped pallet, essential for recalls and continuous improvement.

How to Assess Tooling Design and Build Expertise?

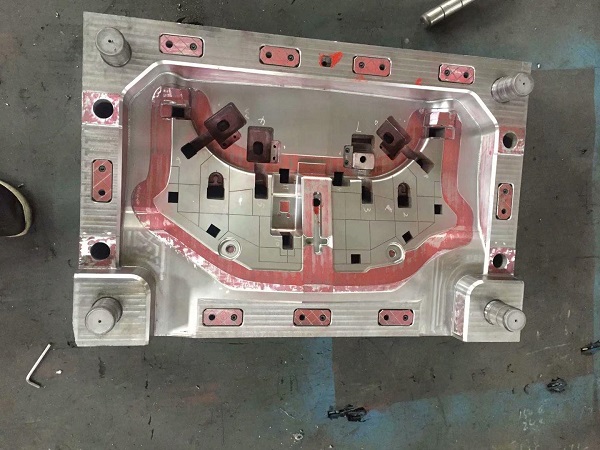

The mold is the heart of the process. In-house mastery here is a massive advantage.

- In-House vs. Outsourced: Prioritize partners with in-house mold design and build capabilities. This integration allows for seamless collaboration, faster iterations, and single-point accountability. A shop that outsources its core tooling relinquishes control over your project's most critical path.

- Design for Manufacturability (DFM) Process: Request a sample DFM report. A strong partner will provide detailed feedback on gate location, wall thickness uniformity, draft angles, and ejection strategy to optimize part quality and mold life.

- Mold Maintenance Program: Ask to see their preventative maintenance schedule for production molds. A formal program is non-negotiable for ensuring uptime and achieving a mold life of 1M+ cycles.

What Material Selection Support Should You Expect?

A true partner guides you to the optimal material, not just the one you request.

- Beyond the Datasheet: They should advise on long-term material stability, creep behavior, chemical resistance, and regulatory compliance (UL, FDA, REACH) specific to your application.

- Cost-Performance Optimization: They might suggest a less expensive material grade or a filled compound that meets all requirements while reducing cost. For instance, recommending a high-flow POM for a complex thin-wall part to reduce injection pressure and improve fill.

- Supply Chain Insight: They should have knowledge of material availability, lead times, and can recommend alternatives to mitigate supply chain risk.

How to Compare Lead-Time Promises Realistically?

Beware of vendors who promise unrealistically short timelines. A professional breakdown is detailed and sequential.

- Phased Timeline: A credible partner will provide a Gantt chart or detailed schedule separating:

- DFM & Quotation Finalization: 1-2 weeks.

- Mold Design: 2-4 weeks.

- Mold Manufacturing: This is the key variable. A simple aluminum prototype mold: 4-6 weeks. A multi-cavity production steel mold: 12-20+ weeks.

- Sampling, Testing, and Approval: 2-4 weeks.

- Ask About Capacity: "What is your current shop capacity for new mold builds and production?" This reveals their ability to meet promises.

Conclusion

Selecting a reliable Plastic Injection OEM Partner is a due diligence process that scrutinizes systems, culture, and technical depth. The right partner is not the one with the lowest price, but the one with the most transparent and robust systems: valid IATF 16949 or ISO 13485 certification, in-house tooling expertise, data-driven quality control, and a collaborative engineering mindset. They become a strategic asset, reducing your time-to-market, mitigating risk, and ensuring your product excels in the hands of the end-user. By applying this structured evaluation framework, you move beyond a transactional relationship to forge a true manufacturing partnership built for success and scale.

FAQ on Choosing a Plastic Injection OEM Partner

What is the difference between an OEM partner and a standard injection molder?

An OEM Partner operates as an extension of your brand, taking ownership of the entire manufacturing process from design input to boxed product. A standard molder typically executes a provided specification with less proactive engineering and supply chain management.

How important is geographic location when choosing a partner?

For products requiring frequent engineering collaboration, just-in-time (JIT) delivery, or lower shipping costs, proximity is a significant advantage. For stable, high-volume products, a capable distant partner with excellent logistics can be very effective. Consider time zones for communication.

Should I ask for customer references?

Absolutely. Ask for 2-3 references from companies with similar part complexity, volume, and industry (e.g., medical, automotive). Specific questions about problem-solving and communication are more revealing than general satisfaction.

What are red flags during a supplier audit?

A disorganized shop floor (poor 5S), lack of real-time SPC charts at presses, outdated or uncalibrated inspection equipment, and an inability to clearly explain their quality escalation process.

How do we negotiate pricing with an OEM partner?

Focus on Total Cost of Ownership, not just piece price. Discuss open-book costing for annual reviews, volume-based price breaks, and terms for engineering changes. The goal is a fair, sustainable price that allows them to invest in quality and innovation.

Contact Yigu technology for custom manufacturing.

At Yigu Technology, we are built to be the Plastic Injection OEM Partner you can rely on. Our integrated approach combines IATF 16949 and ISO 13485 certified systems, full in-house mold design and manufacturing, and a scientific molding production floor. We don't just make parts; we manage projects, mitigate risks, and drive continuous improvement as an accountable extension of your team.

From complex medical devices to high-volume automotive components, we provide the technical depth, systemic quality, and partnership transparency that leading brands demand.

Contact Yigu Technology today to begin a strategic partnership review and receive a detailed capability presentation.