1. Introduction

1.1 The Significance of Precision in Manufacturing

In the highly competitive landscape of modern manufacturing, precision is no longer just a desirable trait; it's the cornerstone of success. Precision determines whether a product functions as intended, meets quality standards, and ultimately satisfies the end - user. Inaccuracies, no matter how small, can lead to a cascade of problems, from product malfunctions to costly recalls. For instance, in the automotive industry, a misaligned or ill - fitting part can cause vibrations, reduced fuel efficiency, and even safety hazards. In electronics, a minor deviation in component size can disrupt electrical connections and compromise device performance. Thus, precision in manufacturing is directly linked to product quality, customer satisfaction, and a company's bottom line.

1.2 Definition and Basics of Precision Plastic Components

Precision plastic components are plastic - made parts that are manufactured to extremely tight tolerances, often within the range of ±0.01 - ±0.1mm or even narrower in some cases. These components are characterized by their high dimensional accuracy, consistent quality, and excellent repeatability. They are produced using advanced manufacturing techniques such as precision injection molding, which requires state - of - the - art equipment, high - quality molds, and strict process control.

These components find applications in a wide array of industries. In the medical field, they are used in devices like insulin pumps, where the precise delivery of medication is crucial. In the aerospace industry, precision plastic components are utilized in aircraft interiors and avionics systems, thanks to their lightweight yet durable properties. The electronics industry heavily relies on them for components like connectors, where even the slightest deviation in size can affect signal transmission. Additionally, in consumer goods such as smartphones, precision plastic parts contribute to the sleek design and functionality of the device.

3. Case Studies: Real - World Examples

3.1 Case Study 1: Automotive Industry

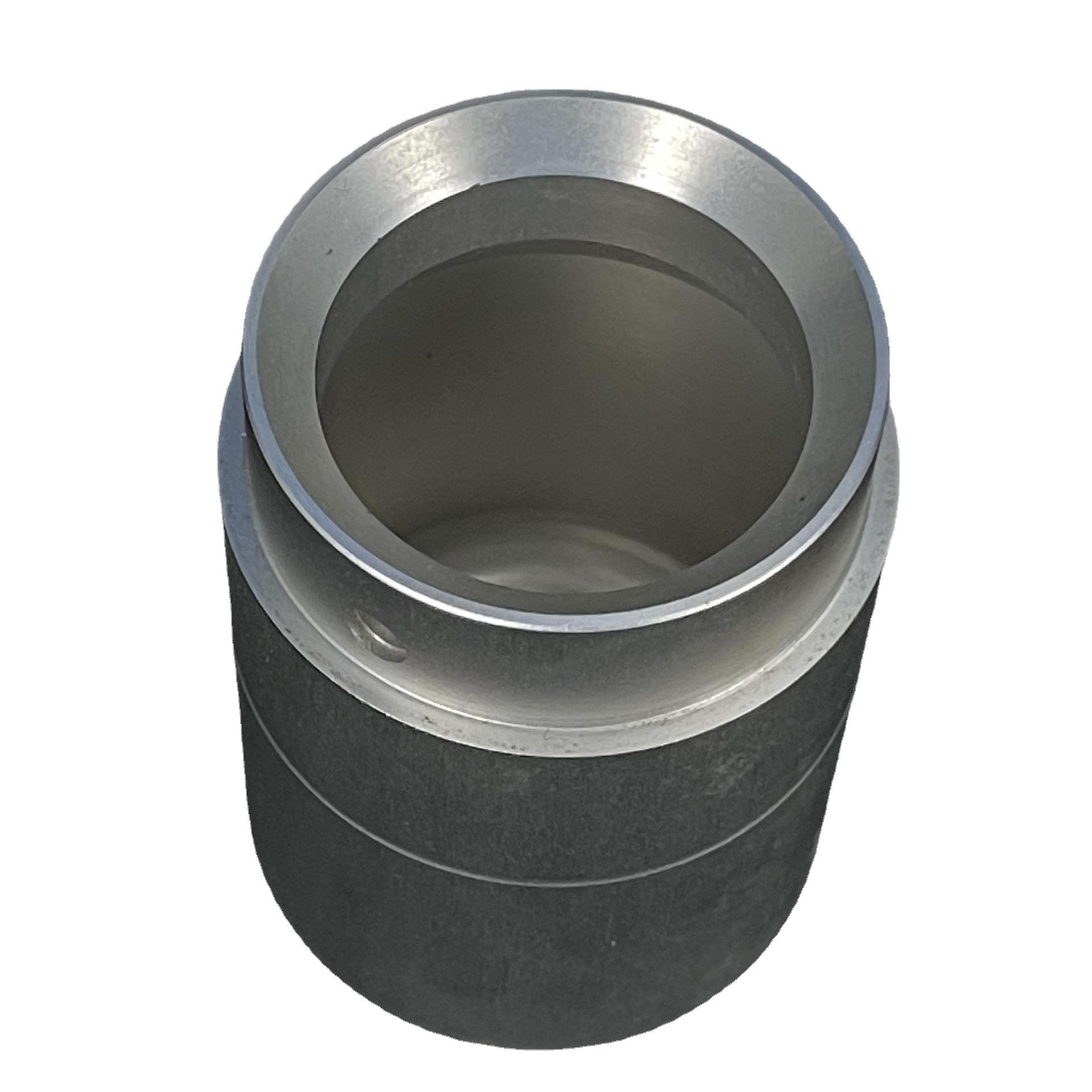

Take the case of a leading automotive manufacturer that was looking to enhance the fuel efficiency and performance of its new line of vehicles. One of the key areas they focused on was the engine cooling system. The company decided to replace some of the traditional metal components in the cooling system with precision plastic components.

They chose precision - injection - molded plastic coolant pipes. These pipes were manufactured to a tolerance of ±0.05mm. The use of these plastic pipes brought several benefits. Firstly, they were significantly lighter than their metal counterparts, reducing the overall weight of the vehicle by about 15 kg for a mid - sized car. According to industry research, a 10% reduction in vehicle weight can lead to a 6 - 8% improvement in fuel efficiency. This weight reduction, combined with the optimized design of the plastic pipes for better coolant flow, improved the fuel efficiency of the vehicle by approximately 7%.

Secondly, the precision manufacturing of the plastic components ensured a perfect fit and connection. There were no leaks or inefficiencies in the coolant flow, which was crucial for maintaining the engine's optimal operating temperature. This led to a decrease in engine overheating incidents by 30% during rigorous testing, improving the reliability and lifespan of the engine. The manufacturer also experienced a reduction in production costs by 20% for this part of the cooling system due to the lower material and machining costs of plastic components.

3.2 Case Study 2: Electronics Industry

In the electronics industry, a major smartphone manufacturer faced the challenge of fitting more components into a smaller and slimmer device while maintaining high - quality performance. They turned to precision plastic components for the design of their new smartphone's internal structure and connectors.

For the internal structure, they used precision - molded plastic frames. These frames were designed with extremely tight tolerances of ±0.03mm to hold the various electronic components in place. The use of these plastic frames allowed for a 20% reduction in the device's thickness, making it one of the thinnest smartphones on the market at that time. This not only enhanced the aesthetic appeal but also improved the portability of the device.

Regarding the connectors, the manufacturer opted for precision - made plastic connectors. These connectors were engineered to ensure a secure and reliable connection between different circuit boards within the phone. In tests, the failure rate of these plastic connectors due to misalignment or poor connection was reduced to less than 0.5%, compared to a 3% failure rate with the previous metal - based connectors. This led to a significant decrease in the number of defective devices, from 5% to 1%, improving the overall quality of the smartphones and reducing customer returns. The use of precision plastic components in the smartphone also contributed to a 15% cost - savings in the manufacturing process, mainly due to the ease of molding and lower material costs of plastics.

4. Yigu Technology's Perspective

As a custom supplier of non - standard plastic and metal products, Yigu Technology understands the critical importance of precision plastic components. They believe that manufacturing precision plastic components requires in - depth knowledge of material properties and processes. With a professional engineering team and advanced equipment, Yigu Technology can meet customers' customization needs for precision plastic components. They oversee the entire process from design to production, ensuring that products meet high - quality standards. By doing so, they assist manufacturers in standing out in the highly competitive market, providing tailored solutions that enhance product performance and reliability.

5. Conclusion

In conclusion, precision plastic components play an indispensable role in modern manufacturing. Their high - dimensional accuracy, cost - effectiveness, and versatility make them a preferred choice across multiple industries. From enhancing product performance in the automotive and electronics sectors to enabling innovation in medical and aerospace applications, these components are the driving force behind the success of many manufacturers.

Looking ahead, the future of precision plastic components appears promising. With the continuous advancement of manufacturing technologies such as 3D printing and the development of new, high - performance plastics, the capabilities of precision plastic component manufacturing are set to expand even further. Manufacturers can expect to see even tighter tolerances, more complex geometries, and improved material properties. This will not only open up new opportunities for product innovation but also drive down costs through more efficient production processes.

As the demand for high - quality, reliable products continues to grow, precision plastic components will remain at the forefront of manufacturing excellence, helping manufacturers to stay competitive in the global marketplace.

FAQ

What are the common materials used for precision plastic components?

Common materials include ABS (Acrylonitrile Butadiene Styrene), known for its strength, impact - resistance, and ease of molding. It's widely used in automotive interiors and consumer electronics. Another popular material is PEEK (Polyether Ether Ketone), which offers high - temperature resistance, excellent mechanical properties, and chemical stability, making it suitable for aerospace and medical applications. Polycarbonate (PC) is also frequently used due to its transparency, high - impact strength, and dimensional stability, often found in optical components and protective covers.

How can manufacturers ensure the quality of precision plastic components?

Manufacturers can ensure quality by implementing strict quality control measures at every stage of production. This includes using high - quality raw materials from reliable suppliers. Advanced inspection equipment such as coordinate measuring machines (CMMs) can be used to measure the dimensions of components during and after production to ensure they meet the specified tolerances. Conducting regular mold maintenance and calibration helps to maintain the accuracy of the injection molding process. Additionally, implementing statistical process control (SPC) can monitor the production process in real - time, detecting and correcting any variations promptly.

What is the typical lead time for custom precision plastic components?

The typical lead time for custom precision plastic components can vary depending on several factors. For simple designs with standard materials, it may be as short as 2 - 4 weeks, which includes design approval, mold making, and production. However, for complex designs, especially those requiring the development of new molds or the use of specialized materials, the lead time can extend to 8 - 12 weeks or even longer. Factors such as the availability of materials, the complexity of the manufacturing process, and the production capacity of the manufacturer also influence the lead time.