What Exactly is Brass?

Brass is a metal alloy primarily composed of copper (Cu) and zinc (Zn). It has been utilized by humans for thousands of years, with its history dating back to ancient civilizations. This alloy is well - known for its unique combination of properties, which are a result of the specific proportions of its constituent elements.

Composition and Color

Typically, brass has a golden - yellow color. However, the exact color can vary depending on the ratio of copper to zinc. When the alloy contains a higher percentage of copper, it may exhibit a reddish hue, and this type is often referred to as “red brass”. Yigu Technology For example, if the copper content is around 85% and the zinc content is 15%, the brass will have a more coppery color. On the other hand, when the zinc content is increased, the color tends to become lighter and more yellow - like.

Influence of Composition on Type and Properties

The precise quantities of copper and zinc in brass play a crucial role in determining its type and properties.

- Mechanical Properties: Generally, as the zinc content increases, the strength and hardness of brass also increase. Yigu Technology For instance, brass with a relatively high zinc content (around 40%) like Muntz Brass (Alloy 280) has a higher tensile strength compared to brass with a lower zinc content. The following table shows the mechanical properties of different brass alloys based on their composition:

| Alloy | Composition (wt %) | Density (g/cm³) | Hardness, Rockwell (F, B) | Yield Strength (MPa) | Ultimate Tensile Strength (MPa) | Elongation @ Break (%) | Modulus of Elasticity (GPa) | Machinability (%) |

| Alloy 260 | Cu: 68.5 - 71.5, Zn: 28.5 - 31.5, Fe ≤ 0.05, Pb ≤ 0.070 | 8.53 | 54 F | 75 | 300 | 68 | 110 | 30 |

| Alloy 280 | Cu: 59 - 63, Zn: 40, Fe ≤ 0.070, Pb ≤ 0.3 | 8.39 | 85 F | 145 | 370 | 45 | 105 | 40 |

| Alloy 360 | Cu: 60 - 63, Zn: 35.5, Fe ≤ 0.35, Pb ≤ 2.5 - 3.7 | 8.49 | 78 B | 124 - 310 | 338 - 469 | 53 | 97 | 100 |

| Alloy 385 | Cu: 55 - 59, Zn: 36.65 - 41.65, Fe ≤ 0.35, Pb ≤ 2.5 - 3.5 | 8.47 | 65 B | 138 | 414 | 30 | 100 | 90 |

| Alloy 464 | Cu: 55 - 59, Zn: 36.65 - 41.65 Zn, Fe ≤ 0.35, Pb ≤ 2.5 - 3.5 | 8.41 | 55 B | 172 - 455 | 379 - 607 | 50 | - | 30 |

- Corrosion Resistance: Some elements added to brass, such as lead, can improve its corrosion resistance. In the case of brass used in marine environments, small amounts of tin are added to enhance its resistance to seawater corrosion. Naval Brass (Alloy 464), which contains approximately 59% copper, 40% percent zinc, and 1% tin, with a small amount of lead, is highly resistant to seawater and is commonly used in marine applications like boat deck fittings.

- Machinability: Brass alloys with specific compositions can have excellent machinability. Free Machining Brass (Alloy C360), Yigu Technology for example, contains approximately 60% copper, 35.5% zinc, up to 3.7% lead, and trace quantities of iron. This composition gives it a 100% machinability rating, making it one of the easiest materials of all the brasses to machine, and it is commonly used for parts like gears and bushings.

The Composition of Brass

As mentioned above, the main components of brass are copper and zinc. However, depending on the specific application requirements, brass may also contain trace amounts of other elements such as lead, iron, tin, aluminum, manganese, nickel, etc. Each of these elements has a specific impact on the properties of brass:

- Lead (Pb): Lead is often added to brass to improve its machinability. In brass alloys like Alloy C360 (Free Machining Brass), which contains up to 3.7% lead, the presence of lead allows the material to be easily cut and shaped during machining processes. This is because lead forms small, discrete particles within the brass matrix. These particles act as stress concentrators during machining, causing the chips to break into small, manageable pieces, which reduces the forces required for cutting and minimizes tool wear. Additionally, lead can also enhance the corrosion resistance of brass to some extent, especially in certain chemical environments.

- Iron (Fe): Iron is added to brass to increase its hardness and strength. For example, in some brass alloys used for manufacturing gears and other mechanical components that require high strength and wear resistance, a small amount of iron (usually less than 1.5%) is included. Iron forms a fine - dispersed phase within the brass matrix, which acts as a reinforcement. This reinforcement effectively restricts the movement of dislocations within the material, making it more difficult for the brass to deform under stress, thus increasing its strength and hardness. However, excessive iron content can lead to the formation of large, brittle iron - rich phases, which may reduce the ductility and corrosion resistance of the brass.

- Tin (Sn): Tin is a crucial element in naval brass (Alloy 464). By adding about 1% tin to the copper - zinc base, the corrosion resistance of brass in seawater is significantly enhanced. Tin forms a protective oxide film on the surface of the brass when it comes into contact with seawater. This film acts as a barrier, preventing the underlying brass from being attacked by the corrosive components in seawater, such as chloride ions. This makes naval brass highly suitable for applications in marine environments, like boat deck fittings, propellers, and seawater - handling pipes.

- Aluminum (Al): Aluminum is added to brass to improve its strength, hardness, and corrosion resistance. In aluminum - brass alloys, aluminum forms a thin, adherent oxide layer on the surface. This oxide layer not only protects the brass from corrosion but also increases its hardness. Additionally, aluminum can also refine the grain structure of brass during solidification, which further improves its mechanical properties. However, too much aluminum can make the brass more brittle, so the amount of aluminum added needs to be carefully controlled.

- Manganese (Mn): Manganese can dissolve in brass to form a solid solution, which effectively strengthens the brass. It also improves the corrosion resistance of brass, especially in acidic environments. Yigu Technology For example, in some brass alloys used in chemical processing equipment, manganese is added to enhance their durability in the presence of corrosive chemicals. Manganese can also improve the hot - working properties of brass, making it easier to shape the material at high temperatures.

- Nickel (Ni): Nickel is added to brass to improve its corrosion resistance and mechanical properties. Nickel - containing brass alloys often have better resistance to oxidation and certain chemical attacks compared to regular brass. Nickel can also enhance the strength and toughness of brass, making it suitable for applications where high - strength and corrosion - resistant materials are required, such as in some high - end plumbing fixtures and marine hardware.

Types of Brass

There are numerous brass alloys, each with its own unique elemental makeup, which results in different properties and applications. Here are some of the most commonly used types:

Alloy 260 (Cartridge Brass)

Alloy 260, also known as Cartridge Brass, contains approximately 70% copper and 30% zinc, along with some impurities. This alloy is highly valued for its excellent hot formability. During hot - working processes, such as hot forging or hot rolling, the atoms in the alloy can move more freely, allowing the material to be easily shaped into complex forms. It is also readily cold - worked, which means it can be shaped at room temperature through processes like cold rolling, stamping, or drawing. This makes it suitable for manufacturing products like bullet cartridges, where precise shaping and high - volume production are required. The high copper content in Alloy 260 also contributes to its relatively good corrosion resistance and attractive golden - yellow color.

Alloy 280 (Muntz Brass / Muntz Metal)

Alloy 280, or Muntz Brass, has a composition of about 60% copper and 40% zinc, with trace amounts of iron. This alloy has a relatively high strength and hardness due to its zinc content. One of its historical applications was as a replacement for copper sheeting on boat hulls. Copper sheeting was originally used to prevent the growth of sea organisms such as barnacles on boat hulls. However, copper was expensive. Muntz Brass provided a more cost - effective solution. The addition of iron in small amounts helps to improve the alloy's strength and hardness, making it more durable in marine environments. Although it is not as corrosion - resistant as some other marine - grade alloys, its combination of cost - effectiveness and reasonable corrosion resistance made it a popular choice for boat hull applications in the past.

Alloy C360 (Free Machining Brass)

Alloy C360, known as Free Machining Brass, contains around 60% copper, 35.5% zinc, up to 3.7% lead, and trace quantities of iron. The addition of lead is the key factor that gives this alloy its outstanding machinability, with a 100% machinability rating. During machining operations such as turning, milling, and drilling, the lead particles in the alloy act as lubricants, reducing the friction between the cutting tool and the brass. This results in smoother cutting, less tool wear, and higher machining speeds. As a result, it is commonly used for manufacturing parts like gears and bushings. Gears need to have precise shapes and smooth surfaces to ensure proper meshing and efficient power transmission, and the excellent machinability of Alloy C360 allows for the production of high - quality gears. Bushings, which are used to reduce friction between moving parts, also benefit from the low - friction properties and easy machinability of this alloy.

Alloy 385 (Architectural Bronze)

Despite its name, Alloy 385 is actually a type of brass. It contains approximately 59% copper, 42% zinc, and up to 3.5% lead. This alloy is highly regarded in the architecture industry, especially for aluminum extrusions. Its relatively high zinc content gives it good strength and formability, allowing it to be easily extruded into various shapes, such as window frames, door handles, and decorative trims. The addition of lead improves its machinability, making it easier to cut, drill, and shape the extruded parts during the manufacturing and installation processes. Its attractive appearance, similar to that of bronze, also makes it a popular choice for architectural applications where aesthetics are important.

Brass 464 Marine Grade, also known as Naval Brass, consists of about 59% copper, 40% zinc, 1% tin, and a small amount of lead. The addition of tin is crucial for its exceptional corrosion resistance to seawater. When exposed to seawater, the tin in the alloy forms a protective oxide film on the surface of the brass. This film acts as a barrier, preventing the underlying metal from being attacked by the corrosive components in seawater, such as chloride ions. As a result, Naval Brass is widely used in marine applications, particularly for fittings found on the deck of a boat, such as hinges, fasteners, and pipes. These fittings need to withstand the harsh marine environment, including saltwater, humidity, and temperature variations, and Naval Brass's corrosion resistance and mechanical properties make it a reliable choice for such applications.

Properties of Brass

Mechanical Properties

The mechanical properties of brass are influenced by its composition and the manufacturing processes it undergoes. Here are some key mechanical properties of common brass alloys:

- Density: The density of brass varies depending on the proportion of copper and zinc. Generally, it ranges from about 8.3 - 8.7 g/cm³. Yigu Technology For example, Alloy 260 has a density of 8.53 g/cm³, while Alloy 280 has a density of 8.39 g/cm³. The higher the copper content, the relatively higher the density tends to be. This is because copper has a higher density (8.96 g/cm³) compared to zinc (7.14 g/cm³).

- Hardness: Brass can have different hardness levels. Hardness is often measured using the Rockwell scale. Alloy 260 has a Rockwell hardness of 54 F, while Alloy 360 has a Rockwell hardness of 78 B. The addition of elements like zinc and lead can increase the hardness of brass. In the case of brass used for gears, a higher hardness is beneficial to resist wear and tear during operation.

- Yield Strength: Yield strength is the stress at which a material begins to deform plastically. Different brass alloys have varying yield strengths. Alloy 260 has a yield strength of 75 MPa, while Alloy 360 has a yield strength ranging from 124 - 310 MPa. The yield strength can be affected by factors such as the amount of cold - working and the presence of alloying elements. Cold - working can increase the yield strength by introducing dislocations into the crystal structure of the brass, making it more difficult for the material to deform.

- Ultimate Tensile Strength: This is the maximum stress a material can withstand before it fractures. Alloy 280 has an ultimate tensile strength of 370 MPa, and Alloy 464 has a range of 379 - 607 MPa. The tensile strength of brass is related to its composition. Yigu Technology For instance, the addition of elements like tin in Naval Brass (Alloy 464) not only improves its corrosion resistance but also contributes to its relatively high tensile strength, making it suitable for applications where the material needs to withstand mechanical stress in a marine environment.

- Elongation @ Break: Elongation at break is a measure of the ductility of a material, indicating how much it can stretch before it breaks. Alloy 260 has an elongation at break of 68%, while Alloy 385 has an elongation at break of 30%. A higher copper content usually leads to better ductility. Brass with high ductility is more suitable for processes like cold - rolling and stamping, as it can be easily shaped without cracking.

- Modulus of Elasticity: The modulus of elasticity, also known as Young's modulus, represents the stiffness of a material. It measures how much a material will deform under an applied load. Brass alloys typically have a modulus of elasticity in the range of 97 - 110 GPa. Yigu Technology For example, Alloy 260 has a modulus of elasticity of 110 GPa, and Alloy 360 has a modulus of elasticity of 97 GPa. A higher modulus of elasticity means the material is stiffer and less likely to deform under a given load. In applications where dimensional stability is crucial, such as in precision - engineered parts, a higher modulus of elasticity can be an important factor.

- Machinability: Machinability is a measure of how easily a material can be cut, drilled, or shaped using machining processes. As mentioned before, Free Machining Brass (Alloy C360) has a 100% machinability rating, while other alloys like Alloy 260 have a lower machinability percentage (30%). The presence of lead in brass alloys like Alloy C360 significantly improves machinability. Lead acts as a lubricant during machining, reducing friction between the cutting tool and the brass, which results in smoother cutting, less tool wear, and higher machining speeds.

Chemical Properties

Brass has certain chemical properties that make it suitable for a wide range of applications:

- Chemical Stability: In general, brass is relatively stable in normal atmospheric conditions. However, over time, it can react with oxygen in the air to form a thin layer of copper oxide on its surface. This process is known as oxidation. The rate of oxidation can be affected by factors such as humidity and the presence of pollutants in the air. For example, in a humid environment, the oxidation of brass may occur more quickly, leading to the formation of a greenish - blue patina over time. This patina, known as verdigris, consists of copper - based salts such as copper carbonate and copper sulfate. Although the patina can change the appearance of brass, it can also provide a certain degree of protection to the underlying metal, slowing down further oxidation.

- Corrosion Resistance: Brass has good corrosion resistance in many environments. In freshwater and most non - acidic environments, it can maintain its integrity for a long time. For example, brass pipes are commonly used in plumbing systems because they can resist corrosion from water and the chemicals typically found in tap water. However, the corrosion resistance of brass can be enhanced or reduced depending on its composition. Naval Brass (Alloy 464), with its addition of tin, has excellent corrosion resistance in seawater. The tin forms a protective oxide film on the surface of the brass when it comes into contact with seawater, preventing the underlying metal from being attacked by the corrosive components in seawater, such as chloride ions. On the other hand, if the brass contains a relatively high amount of zinc, it may be more prone to a form of corrosion called dezincification. Dezincification occurs when zinc is selectively leached out of the brass alloy in certain environments, especially in acidic or high - humidity conditions. This can lead to a weakening of the material and a change in its mechanical properties. To prevent dezincification, some brasses are treated with inhibitors or contain elements like arsenic, antimony, or phosphorus, which can help to suppress the process.

- Reaction with Acids and Bases: Brass can react with acids and bases, but the reaction rate and the nature of the reaction depend on the type and concentration of the acid or base. Yigu Technology For example, when brass comes into contact with hydrochloric acid (HCl), the zinc in the brass reacts with the acid to produce hydrogen gas and zinc chloride. The chemical equation for this reaction is: Zn + 2HCl → ZnCl₂+ H₂↑. The copper in the brass may also react to a lesser extent, depending on the concentration and temperature of the acid. In the presence of strong oxidizing acids like nitric acid (HNO₃), brass can undergo a more complex reaction. Nitric acid can oxidize both copper and zinc, producing metal nitrates and various nitrogen - containing oxides. The reaction with bases is generally less common but can occur under certain conditions. For instance, zinc in brass can react with strong alkalis like sodium hydroxide (NaOH) to form sodium zincate and hydrogen gas: Zn + 2NaOH + 2H₂O → Na₂[Zn(OH)₄]+ H₂↑. However, brass is often used in applications where it is not likely to come into contact with highly concentrated acids or bases.

Applications of Brass

In the Industrial Field

Brass has a wide range of applications in the industrial field. Its excellent machinability makes it an ideal material for manufacturing various tools. For example, brass is often used to make screwdriver heads. The relatively soft nature of brass allows for easy shaping during the manufacturing process, and it also provides good corrosion resistance, ensuring that the tool will not rust easily in normal working environments.

In the production of valves, brass is highly favored. Valves made of brass can withstand a certain degree of pressure and are resistant to corrosion from various fluids. In water supply systems, brass valves are commonly used to control the flow of water. Their corrosion resistance ensures that they can maintain their functionality over a long period, even when in contact with water that may contain trace amounts of chemicals. In chemical processing plants, brass valves are used to handle non - acidic or mildly acidic fluids. The corrosion - resistant properties of brass, especially in certain chemical environments, make it suitable for these applications.

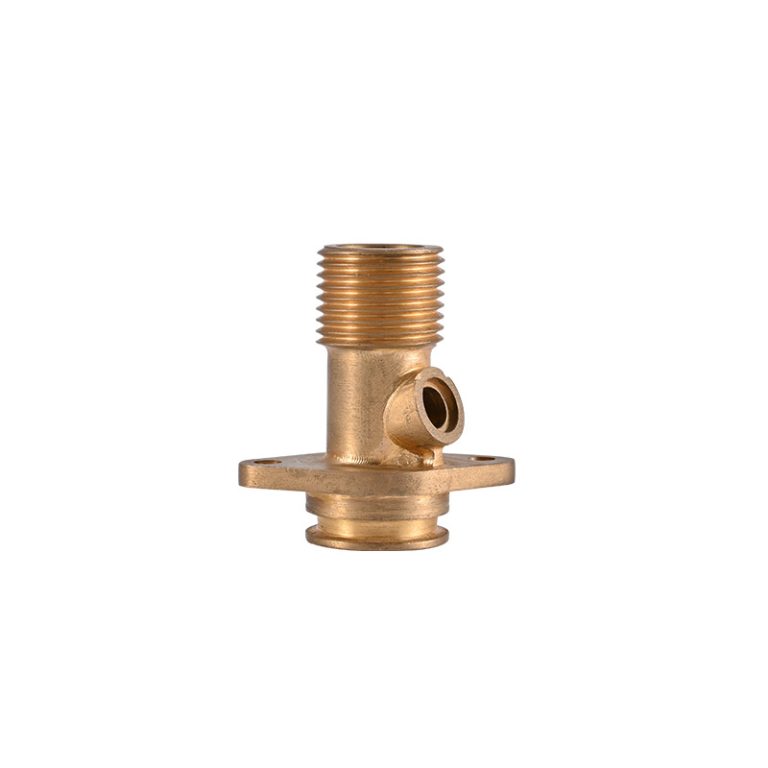

Pipes and fittings are also important applications of brass in the industrial field. Brass pipes are often used in plumbing systems due to their corrosion resistance and ease of installation. They can be easily bent and joined together using soldering or compression fittings. In heating systems, brass pipes are used to transport hot water. Their ability to resist corrosion from hot water and the chemicals present in it ensures the long - term reliability of the heating system. Brass fittings, such as elbows, tees, and couplings, are used to connect pipes. These fittings need to have good mechanical properties to ensure a tight and leak - free connection. The high strength and formability of brass make it possible to produce fittings with precise shapes and dimensions, which are essential for the proper functioning of piping systems.

In Daily Life

Brass is commonly found in many daily - life items. Door handles are a prime example. Brass door handles are not only aesthetically pleasing, with their attractive golden - yellow color, but also offer antibacterial properties. The copper content in brass can kill certain types of bacteria, making it a hygienic choice for high - touch surfaces like door handles. In public buildings, such as hospitals, schools, and offices, brass door handles can help reduce the spread of germs. Additionally, brass door handles are durable and can withstand frequent use without easily wearing out.

Hinges are another area where brass is frequently used. Brass hinges are known for their strength and durability. They can support the weight of doors and cabinets while allowing for smooth opening and closing. The low - friction properties of brass also contribute to the ease of operation of hinges. In high - traffic areas, such as commercial buildings or busy households, brass hinges are a reliable choice as they can withstand repeated use without breaking or becoming loose. Their corrosion resistance ensures that they will not rust over time, even in humid environments, maintaining their functionality and appearance.

In the Musical Instrument Industry

Brass plays a crucial role in the musical instrument industry, especially in the production of brass instruments. Trumpets, trombones, French horns, and tubas are all made from brass. The unique acoustic properties of brass make it an ideal material for these instruments. When air is blown through a brass instrument, the vibrations of the air column interact with the walls of the instrument. Brass has a specific density and elasticity that help to produce a rich, warm, and characteristic sound.

The thickness and shape of the brass used in musical instruments also have a significant impact on the sound quality. For example, in a trumpet, the thickness of the brass tubing affects the resonance of the instrument. A thinner tubing may produce a brighter sound, while a thicker tubing can result in a more mellow and powerful sound. The bell - shaped end of a brass instrument, which is usually made of brass, also plays a vital role in shaping the sound. It helps to project the sound outwards and gives the instrument its characteristic timbre. Musicians often prefer brass instruments made from high - quality brass alloys because they can produce a more consistent and pleasing sound. The manufacturing process of brass musical instruments also requires precision to ensure that the instrument has the correct pitch and tone. Skilled craftsmen use specialized techniques to shape the brass into the desired form, taking into account the acoustic requirements of the instrument.

Advantages and Disadvantages of Brass

Advantages

- Ease of Machining: As mentioned before, some brass alloys like Free Machining Brass (Alloy C360) have a 100% machinability rating. The presence of lead in this alloy acts as a lubricant during machining operations such as turning, milling, and drilling. This reduces the friction between the cutting tool and the brass, resulting in smoother cutting, less tool wear, and higher machining speeds. For example, in the production of small precision parts for electronics, the easy - machinability of brass allows manufacturers to produce parts with high precision and complex shapes at a relatively low cost.

- Low Coefficient of Friction: Brass has a low coefficient of friction, which means its surface is smooth and slippery. This property makes it an ideal material for parts that need to slide against each other without wearing down quickly. In mechanical systems, bushings made of brass are often used to reduce friction between moving parts. For instance, in a car engine, brass bushings are used in the crankshaft and camshaft systems. The low - friction property of brass helps to reduce energy losses due to friction, improve the efficiency of the engine, and extend the service life of the components.

- Antibacterial Properties: The copper content in brass can kill certain types of bacteria. This makes it a popular choice for high - touch surfaces. In hospitals, brass door handles and handrails are used to reduce the spread of harmful bacteria. Studies have shown that brass surfaces can significantly reduce the survival rate of bacteria such as E. coli and Staphylococcus aureus within a few hours. This antibacterial property also makes brass suitable for use in the food industry, where hygiene is crucial. Yigu Technology For example, some food - processing equipment, such as valves and fittings, are made of brass to prevent bacterial contamination of food products.

- Anti - biofouling Properties: In marine environments, brass's anti - biofouling properties are highly valued. Algae and barnacles will not grow on brass surfaces easily. This is because the metal ions in brass can inhibit the attachment and growth of marine organisms. Naval Brass (Alloy 464) is often used in the construction of boats and ships. The anti - biofouling property of this brass alloy helps to keep the hull and deck fittings clean, reducing the need for frequent cleaning and maintenance. It also improves the hydrodynamic performance of the vessel, as a clean hull experiences less drag in the water, resulting in better fuel efficiency.

Disadvantages

- Prone to Tarnishing: Brass is prone to tarnishing. If not properly maintained, it can form unsightly blackish stains due to oxidation. When brass is exposed to air, the copper in it reacts with oxygen to form copper oxide. In a humid environment, the oxidation process is accelerated, and the formation of a greenish - blue patina (verdigris) may also occur over time. To prevent tarnishing, many manufacturers coat brass with a clear lacquer. This lacquer acts as a barrier, preventing oxygen and moisture from coming into contact with the brass surface. In some decorative brass items, regular polishing with a suitable metal polish can also help to remove the tarnish and maintain the shiny appearance of the brass.

- Non - hypoallergenic: Brass is non - hypoallergenic because of its copper and zinc content. It can cause some skin irritation to people with sensitive skin. When the skin comes into contact with brass for an extended period, the metal ions in brass can be absorbed by the skin, leading to allergic reactions such as redness, itching, and rashes. Treating brass with a lacquer coating can prevent skin contact with the metal ions, reducing the risk of allergic reactions. In the design of jewelry or personal accessories made of brass, manufacturers may also use alternative coatings or platings, such as nickel - plating or gold - plating, to make the products more skin - friendly.

- High Cost: Brass is more expensive than some other metals due to its high copper content. Copper is a relatively expensive metal, and as the main component of brass, it contributes significantly to the cost of the alloy. In large - scale industrial applications where cost - effectiveness is a crucial factor, the high cost of brass may limit its use. For example, in some construction projects that require a large amount of metal for structural purposes, cheaper metals like steel may be preferred over brass. However, in applications where the unique properties of brass are essential, such as in high - end plumbing fixtures or musical instruments, the cost is often justified by the performance and quality that brass provides.

Comparison with Other Metals

Copper

Copper and brass are both important materials in the metal family, but they have distinct differences in composition, properties, and applications.

- Composition: Copper is a pure metal with the chemical symbol Cu. It has a high purity level, often reaching 99.5% or more in its industrial forms. Brass, on the other hand, is an alloy primarily composed of copper and zinc. The proportion of copper in brass can vary, usually ranging from around 55% - 90%, with the remaining being zinc and sometimes small amounts of other elements like lead, iron, or tin. For Yigu Technology example, in Alloy 260 (Cartridge Brass), it contains about 70% copper and 30% zinc.

- Properties:

- Conductivity: Copper is well - known for its excellent electrical conductivity. It has one of the highest electrical conductivities among common metals, which makes it the material of choice for many electrical applications such as wiring in buildings, electrical cables, and components in electronic devices. Brass, due to the addition of zinc and other elements, has a lower electrical conductivity compared to pure copper. However, it still has sufficient conductivity for applications like electrical connectors and some low - voltage electrical components.

- Corrosion Resistance: Copper has good corrosion resistance in normal atmospheric conditions. It forms a thin oxide layer on its surface over time, which can provide some protection against further corrosion. In certain environments, such as in the presence of sulfur - containing compounds, copper can react to form copper sulfide, which may affect its appearance and performance. Brass also has good corrosion resistance, especially in freshwater and non - acidic environments. Some types of brass, like Naval Brass with the addition of tin, are highly resistant to seawater corrosion. However, brass can be more prone to dezincification in certain conditions, where zinc is selectively leached out of the alloy, which can weaken the material.

- Hardness and Strength: Pure copper is relatively soft and malleable. It has a lower hardness compared to brass. Brass, with its alloyed elements, generally has a higher hardness and strength. The addition of zinc increases the strength of the alloy, and the presence of other elements like lead can improve its machinability and further affect its mechanical properties. For example, Muntz Brass (Alloy 280) with its relatively high zinc content has a higher tensile strength compared to pure copper.

- Applications:

- Copper Applications: Copper is widely used in the electrical industry. In power generation, transmission, and distribution systems, copper wires and cables are essential for efficiently transmitting electricity. In electronic devices, copper is used in printed circuit boards, connectors, and components to ensure reliable electrical connections. Copper's high thermal conductivity also makes it useful in heat - transfer applications such as heat exchangers in air - conditioning systems and radiators in engines.

- Brass Applications: Brass, with its good machinability, is often used in the manufacturing of mechanical parts. It is used to make gears, bushings, valves, and fittings. In the plumbing industry, brass pipes and fittings are popular due to their corrosion resistance and ease of installation. Brass is also used in decorative applications, such as in the production of door handles, hinges, and decorative hardware, because of its attractive golden - yellow color.

Bronze

Bronze and brass are both copper - based alloys, but they have notable differences in their composition, properties, and applications.

- Composition: Bronze is an alloy that originally referred to a copper - tin alloy, but now it encompasses a wider range of copper - based alloys with various alloying elements such as aluminum, silicon, lead, beryllium, and manganese. For example, a typical tin - bronze may contain 80% - 90% copper, 2% - 8% tin, and small amounts of other elements like phosphorus. In contrast, brass is mainly a copper - zinc alloy, with zinc being the primary alloying element, as mentioned before.

- Properties:

- Main Alloying Elements and Their Effects: In bronze, tin is a common alloying element that significantly improves the alloy's hardness, strength, and corrosion resistance, especially in seawater. Aluminum in aluminum - bronze can enhance the alloy's strength, hardness, and corrosion resistance in various environments, including seawater and acidic conditions. In brass, zinc is the main alloying element that affects its strength, hardness, and color. As the zinc content increases, the strength and hardness of brass generally increase, and the color becomes lighter.

- Characteristics: Bronze often has excellent casting properties. It can fill complex molds accurately during the casting process, making it suitable for manufacturing intricate parts. Bronze also has good wear resistance, which makes it ideal for applications where parts are subject to friction, such as bearings and bushings. Brass, while having good machinability and formability, may not have the same level of wear resistance as some bronzes. For Yigu Technology example, in a mechanical system where a component needs to withstand high - speed rotation and friction, a bronze bearing would be a better choice than a brass one.

- Applications: Bronze is commonly used in marine applications due to its high corrosion resistance in seawater. Ship propellers, marine hardware, and parts of seawater - handling equipment are often made of bronze. In the manufacturing of musical instruments, some high - end cymbals are made of bronze because of its unique acoustic properties. Bronze is also used in the production of art objects and sculptures due to its aesthetic appeal and workability. Brass, as mentioned earlier, is used in a wide range of applications, including plumbing, electrical components, and decorative items. In the musical instrument industry, brass is used to make instruments like trumpets, trombones, etc., which have a different sound quality compared to those made of bronze.

Frequently Asked Questions about Brass

How Strong is Brass?

Brass is relatively strong and durable, but its strength level depends on factors such as its composition and the heat treatment it has undergone. For example, Naval Brass, when cold - drawn and annealed, can have a tensile strength of up to 580 MPa, which is comparable to some steel grades. The strength of brass makes it suitable for applications where it needs to withstand mechanical stress. In the manufacturing of valve bodies, heat - treated brass is strong enough to endure high pressures. This is because the heat - treatment process can change the microstructure of brass, making it more resistant to deformation under pressure.

Is Brass Safe to Use?

Brass is generally safe for use in general engineering applications. However, it is not recommended for contact with acidic food (pH < 6). This is because the copper and zinc in brass can react with acidic substances, which may lead to the leaching of metal ions into the food. These metal ions, especially copper ions, can have a negative impact on human health if ingested in large amounts. Additionally, brass is toxic to some microscopic organic life due to the effect of copper ions on various microscopic living organisms. For people with skin sensitivity, brass can also cause allergic reactions. When the skin comes into contact with brass, the metal ions in brass can be absorbed by the skin, leading to symptoms such as redness, itching, and rashes.