What is Rapid Tooling Systems?

Rapid tooling systems, also known as RT, is an advanced manufacturing technology that allows for the quick production of molds and tooling. According to a report by MarketsandMarkets, the global rapid prototyping and tooling market is projected to grow from \(12.8 billion in 2023 to \)23.3 billion by 2028, at a Compound Annual Growth Rate (CAGR) of 12.7% during the forecast period. This growth clearly shows the rising importance and adoption of rapid tooling systems in various industries.

Definition

In simple terms, rapid tooling systems are a set of techniques and processes used to create molds, dies, and other tooling components in a much shorter time compared to traditional methods. These systems are designed to bridge the gap between product design and mass production, enabling companies to quickly test and validate their product concepts before moving on to large - scale manufacturing.

Working Principle

The working principle of rapid tooling systems often involves the integration of multiple advanced technologies. For example, many rapid tooling processes start with a 3D CAD (Computer - Aided Design) model of the product. This digital model serves as the basis for all subsequent operations.

One common method is 3D printing, also known as additive manufacturing. In this process, materials such as plastics, metals, or composites are deposited layer by layer based on the 3D CAD model data. For instance, in selective laser sintering (SLS), a high - power laser is used to sinter powdered materials together. The laser selectively fuses the powder particles in each layer according to the cross - sectional shape of the part from the CAD model. Once one layer is complete, a new layer of powder is spread, and the process is repeated until the entire tooling component is formed.

Another related technique is CNC (Computer Numerical Control) machining. After the initial 3D model is created, CNC machines can be programmed to precisely cut and shape the raw materials into the desired tooling components. CNC machining offers high precision and can work with a wide range of materials, including metals, plastics, and woods.

How Does Rapid Tooling Systems Work?

The operation of rapid tooling systems is a multi - step process that combines digital design, advanced manufacturing techniques, and material processing.

- Design Phase:

- 3D CAD Modeling: The journey begins with creating a 3D CAD model of the product or the part for which the tooling is required. This model serves as a digital blueprint, containing all the geometric and dimensional information. Designers use specialized CAD software to create highly detailed models. For example, in the automotive industry, when developing a new interior component, designers will use CAD software to precisely define the shape, size, and any intricate details such as grooves or curves.

- Manufacturing Phase:

- 3D Printing (Additive Manufacturing):

- Fused Deposition Modeling (FDM): One of the most common 3D printing methods in rapid tooling. In FDM, a thermoplastic filament is fed into an extruder, which heats the material to its melting point. The extruder then deposits the molten plastic layer by layer onto a build platform, following the cross - sectional shapes from the 3D CAD model. This method is suitable for creating prototypes or low - volume production tooling components. For instance, a small - scale manufacturer of consumer electronics might use FDM to quickly produce a mold for a new smartphone case design.

- Selective Laser Sintering (SLS): As mentioned earlier, SLS uses a high - power laser to sinter powdered materials. It is often used for producing more durable tooling components, especially when working with materials like nylon or metal powders. For example, in the aerospace industry, SLS can be used to create complex jigs and fixtures for aircraft assembly.

- CNC Machining:

- Milling: CNC milling machines use rotating multi - point cutting tools to remove material from a solid block (the workpiece). The machine follows the toolpath programmed based on the 3D CAD model. This process can create highly accurate and complex shapes. For example, a mold for a plastic toy might be milled from a block of aluminum using a CNC milling machine.

- Turning: In CNC turning, the workpiece rotates while a cutting tool removes material to create a cylindrical shape. This is useful for producing components like shafts or bushings for tooling systems. For example, in the production of injection molds, CNC turning can be used to create the cylindrical cores and cavities with tight tolerances.

- Post - Processing Phase:

- Surface Finishing: After the tooling components are fabricated, they often require surface finishing operations. This can include processes like polishing, sandblasting, or electroplating. Polishing can improve the surface smoothness of a mold cavity, which is crucial for achieving a high - quality finish on the final product. Sandblasting can be used to create a specific texture on the tooling surface. Electroplating, such as chrome plating, can enhance the durability and corrosion resistance of the tooling.

- Assembly: If the tooling system consists of multiple components, they need to be assembled accurately. This involves aligning and fastening the parts together according to the design specifications. For example, in a multi - cavity injection mold, the individual cavity inserts, runners, and ejector systems need to be precisely assembled to ensure proper functionality.

The following table summarizes the main differences between 3D printing and CNC machining in rapid tooling systems:

| Aspect | 3D Printing | CNC Machining |

| Material Usage | Additive, less material waste | Subtractive, more material waste |

| Complexity of Shapes | Can create highly complex geometries easily | Can create complex shapes but may require more setup for extremely complex designs |

| Production Speed for Small Quantities | Faster for small - scale production | Slower for small - scale, more efficient for larger volumes |

| Precision | Generally good, but may have some limitations in high - precision applications | High precision, can achieve tight tolerances |

Applications of Rapid Tooling Systems

Rapid tooling systems have found widespread applications across various industries due to their ability to reduce lead times and costs. Here are some of the key industries where rapid tooling systems are making a significant impact:

- Automotive Industry

- Prototyping: In the automotive industry, rapid tooling systems are used to quickly produce prototypes of new vehicle parts. For example, General Motors used rapid tooling to create prototypes of a new engine block. By using 3D printing in the rapid tooling process, they were able to reduce the prototyping time from several months to just a few weeks. This allowed them to test the design more quickly and make necessary improvements before mass production.

- Custom Parts Production: Rapid tooling also enables the production of custom - made parts for low - volume production runs or aftermarket parts. A study by the Society of Automotive Engineers (SAE) found that companies using rapid tooling for custom parts production could reduce costs by up to 30% compared to traditional manufacturing methods.

- Aerospace Industry

- Jigs and Fixtures: The aerospace industry requires highly precise jigs and fixtures for aircraft assembly. Rapid tooling systems, such as SLS 3D printing, are used to create these components. Boeing, for instance, has been using rapid tooling to produce lightweight jigs and fixtures. These 3D - printed fixtures are not only lighter but also can be produced in a fraction of the time compared to traditional machined fixtures. This has led to a 20% reduction in assembly time for some of their aircraft models.

- Engine Components Prototyping: Rapid tooling helps in the rapid prototyping of engine components. According to a report by the International Aerospace Review, the use of rapid tooling in engine component prototyping has reduced the development cycle by an average of 40%.

- Electronics Industry

- Mold Making for Consumer Electronics: In the production of consumer electronics like smartphones and tablets, rapid tooling is used to create molds for plastic enclosures. Apple, during the development of a new tablet model, used rapid tooling to quickly produce molds for the device's casing. This allowed them to get the product to market faster, gaining a competitive edge. The use of rapid tooling reduced the mold - making time by 50%, from the traditional 8 - 10 weeks to just 4 - 5 weeks.

- Custom Circuit Board Fixtures: Custom fixtures for circuit board assembly can be produced using rapid tooling. A research by the Institute of Electrical and Electronics Engineers (IEEE) showed that companies in the electronics industry that adopted rapid tooling for custom fixture production improved their production efficiency by 35%.

Yigu Technology's View

As a non - standard plastic and metal products custom supplier, Yigu Technology highly values rapid tooling systems. We understand that in today's fast - paced market, the ability to quickly produce high - quality tooling is crucial for our customers' success.

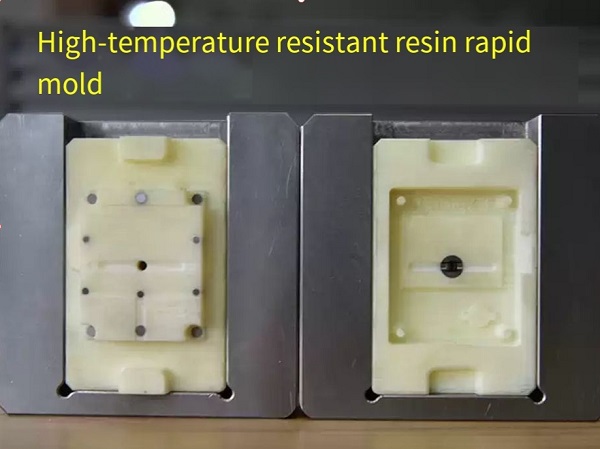

Our advanced equipment and skilled technicians enable us to utilize rapid tooling techniques such as 3D printing and CNC machining effectively. For plastic products, we can use 3D printing to create complex molds with fine details in a short time, reducing the lead time for our customers' new product development. When it comes to metal products, our high - precision CNC machining ensures that the tooling components meet the tightest tolerances.

We also offer comprehensive services from design to post - processing. Our design team can work closely with customers to optimize the 3D CAD models for rapid tooling production. In post - processing, we have a variety of surface finishing options to enhance the performance and appearance of the tooling. By choosing Yigu Technology, customers can benefit from our expertise in rapid tooling systems, ensuring efficient production and high - quality non - standard plastic and metal products.

FAQ about Rapid Tooling Systems

What industries is rapid tooling systems mainly used in?

Rapid tooling systems are mainly used in the automotive industry for prototyping and custom parts production, the aerospace industry for jigs and fixtures and engine components prototyping, and the electronics industry for mold making of consumer electronics and custom circuit board fixtures. Additionally, it is also applied in industries such as medical, where it can be used to quickly produce customized surgical tools; and consumer goods, for rapid development of new product designs.

How much can rapid tooling systems reduce production time?

Compared to traditional manufacturing methods, rapid tooling systems can significantly reduce production time. For example, in the prototyping stage, the time can be cut down by 40% - 60%. In mold - making for consumer electronics, rapid tooling has reduced the mold - making time by about 50%, from the traditional 8 - 10 weeks to 4 - 5 weeks. In the automotive industry, the prototyping time of some parts can be reduced from several months to just a few weeks.

Is the cost of rapid tooling systems high for small - scale production?

For small - scale production, the cost of rapid tooling systems is relatively low. Traditional manufacturing methods often have high upfront costs for tooling setup, especially for complex molds. In contrast, rapid tooling systems, like 3D printing in rapid tooling, can produce small - scale parts without the need for expensive mass - production tooling. A study in the automotive industry found that using rapid tooling for custom parts production in small - scale runs could reduce costs by up to 30% compared to traditional methods. However, for large - scale production, the per - unit cost advantage of rapid tooling may decrease as traditional high - volume manufacturing methods can achieve economies of scale more effectively.