What is Professional 3D Printing Service?

Professional 3D printing service goes far beyond the basic 3D printing that you might do at home or in a casual hobbyist setting. It represents a high - end, industrial - grade solution tailored to meet the exacting demands of various industries.

Higher Precision

One of the most striking differences between professional and ordinary 3D printing is precision. Professional 3D printers can achieve tolerances as low as ±0.05mm or even better in some advanced models. For example, in the aerospace industry, where components need to fit together with extreme accuracy, a professional 3D printing service can produce parts that meet these tight specifications. In contrast, a typical consumer - level 3D printer may have a tolerance of around ±0.2 - 0.5mm, which is far from sufficient for many industrial applications.

Diverse Material Selection

Professional 3D printing services offer an extensive range of materials. While a home 3D printer is often limited to basic plastics like PLA (Polylactic Acid) and ABS (Acrylonitrile Butadiene Styrene), professional services can work with materials such as high - strength engineering plastics (e.g., PEEK - Polyether Ether Ketone), various metals (e.g., aluminum, titanium, stainless steel), ceramics, and even composite materials. For instance, in the medical field, biocompatible materials like some types of resins can be used to create custom - made prosthetics. These materials are carefully selected based on the specific requirements of the project, whether it's heat resistance, chemical resistance, or mechanical strength.

Advanced Post - Processing

After the 3D printing process, professional services also provide advanced post - processing options. This can include processes like sandblasting to smooth the surface, heat - treating to improve the material's mechanical properties, and electroplating to add a protective or decorative layer. In the automotive industry, for example, 3D - printed parts may be post - processed to give them a finish similar to traditional manufacturing methods, ensuring they meet both aesthetic and functional requirements.

The Process of Professional 3D Printing

Professional 3D printing service follows a well - defined and intricate process to ensure high - quality results.

Design Modeling

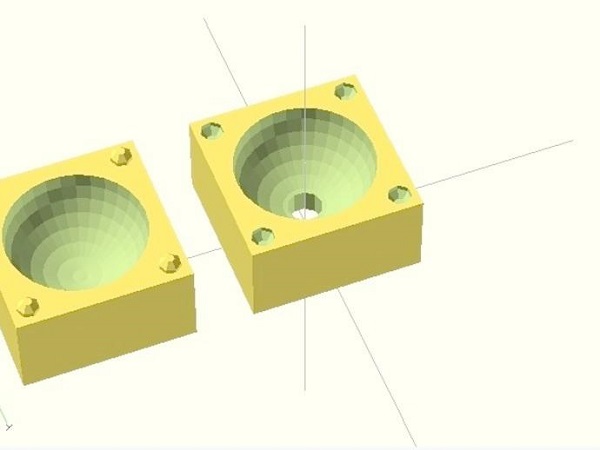

The journey begins with creating a 3D model. This can be done through Computer - Aided Design (CAD) software, where designers can precisely define every detail of the object. For example, in product design, designers use CAD to design a new smartphone case. They can specify the exact dimensions, curves, and cutouts for buttons and ports. Another option is 3D scanning, which is useful for replicating existing objects. Archaeologists might use 3D scanning to create a digital model of a rare artifact before 3D printing a replica for research or display purposes.

Slice Processing

Once the 3D model is ready, it needs to be sliced into thin layers. This is where slicer software comes in. The slicer takes the 3D model and divides it into hundreds or even thousands of horizontal cross - sections. It also generates a G - code, which is a set of instructions that the 3D printer can understand. The layer thickness can be adjusted according to the desired level of detail. For a high - precision jewelry piece, a very thin layer thickness of 0.05mm might be used, while for a large - scale architectural model, a layer thickness of 0.2mm could be sufficient.

Printing

During the printing stage, the 3D printer brings the digital model to life by depositing materials layer by layer according to the G - code instructions. Different 3D printing technologies are used based on the material and application. For instance, in Fused Deposition Modeling (FDM), a common technology, a thermoplastic filament is melted and extruded through a nozzle to build up the layers. In Selective Laser Sintering (SLS), a laser is used to sinter powdered materials, such as nylon or metal powders, together.

Post - Processing

After the printing is complete, post - processing is often required. This can include removing support structures that were used during printing to hold up overhanging parts. In some cases, the printed object may need to be sanded to achieve a smooth surface. For example, a 3D - printed plastic figurine might have visible layer lines that can be removed through sanding. Heat - treating can also be done to improve the mechanical properties of the printed part. A metal 3D - printed component for an engine might be heat - treated to increase its strength and durability.

Yigu Technology's Perspective

As a non - standard plastic and metal products custom supplier, Yigu Technology highly values professional 3D printing services. In the process of custom - making products, 3D printing plays a crucial role.

For non - standard plastic products, 3D printing enables us to quickly produce prototypes with complex shapes. This allows our customers to visualize their product ideas in a short time and make timely adjustments. For example, when developing a new - shaped plastic component for a special - purpose device, traditional manufacturing methods might take weeks to create a prototype, while 3D printing can complete it in just a few days.

In terms of metal products, professional 3D printing services can handle materials like aluminum and titanium, which are difficult to process with traditional methods. It also offers high - precision manufacturing, ensuring that the custom - made metal parts meet strict quality requirements. By using 3D printing, we can also optimize the structure of metal components, reducing weight while maintaining strength, which is especially beneficial for applications in the aerospace and automotive industries. Overall, professional 3D printing services are an essential tool for Yigu Technology to provide high - quality, customized products to meet the diverse needs of our customers.

Real-world Applications

Real - world Applications

Professional 3D printing services have found their way into a wide range of industries, revolutionizing the way products are designed, prototyped, and produced.

Healthcare

In the healthcare industry, 3D printing has become an invaluable tool. For example, it is used to create patient - specific anatomical models. Surgeons can print out a 3D model of a patient's heart before a complex heart surgery. This allows them to better understand the patient's unique anatomy, plan the surgery more effectively, and even practice the procedure in advance. According to a study, in 80% of complex surgeries where 3D - printed anatomical models were used, the surgery time was reduced by an average of 20 - 30 minutes. Also, 3D printing is used to manufacture custom - made prosthetics. These prosthetics can be designed to fit the exact shape and needs of the patient, providing a more comfortable and functional solution compared to off - the - shelf options.

Aerospace

Aerospace companies rely heavily on professional 3D printing services. The ability to produce lightweight yet strong components is crucial in this industry. For instance, Airbus has been using 3D printing to create various aircraft parts. By using 3D - printed titanium brackets, they were able to reduce the weight of these components by up to 40% while maintaining their structural integrity. This weight reduction directly contributes to fuel savings and increased aircraft efficiency. In addition, 3D printing allows for the production of complex geometries that are difficult to achieve with traditional manufacturing methods, such as internal cooling channels in engine components.

Automotive

The automotive industry also benefits greatly from professional 3D printing. It is used for rapid prototyping. Car manufacturers can quickly print out prototypes of new car parts, such as a new dashboard design or a unique car body panel. This speeds up the design and development process, allowing for faster iterations and cost - effective testing. For example, Ford uses 3D printing to produce prototypes of engine components. They can test these components for functionality and performance before moving on to mass production. In addition, 3D printing can be used for producing custom - made parts for classic cars or high - end luxury vehicles, where traditional manufacturing methods may be too expensive or time - consuming.

FAQ

What types of materials can be used in professional 3D printing?

Common materials include high - strength engineering plastics like PEEK, various metals such as aluminum, titanium, and stainless steel, ceramics, and composite materials. There are also biocompatible resins for medical use, and heat - resistant, chemical - resistant materials for specific industrial applications.

How accurate are professional 3D printers?

Professional 3D printers can generally achieve tolerances in the range of ±0.05 - 0.2mm, depending on the technology and model. For example, some advanced metal 3D printers can reach a tolerance of ±0.05mm, while certain high - end plastic printers can achieve ±0.1mm.

What is the typical turnaround time for a 3D printing project?

For small and simple 3D - printed parts, the turnaround time can be as short as 1 - 3 days. Larger and more complex projects may take anywhere from 1 - 2 weeks, considering factors like design complexity, material availability, and post - processing requirements.