What is Big Area Additive Manufacturing?

Big Area Additive Manufacturing, often abbreviated as BAAM, is an advanced manufacturing technology that represents a significant leap forward from traditional manufacturing methods. At its core, BAAM is a form of 3D printing that focuses on creating large - scale objects by depositing materials layer by layer.

The Layer - by - Layer Construction Process

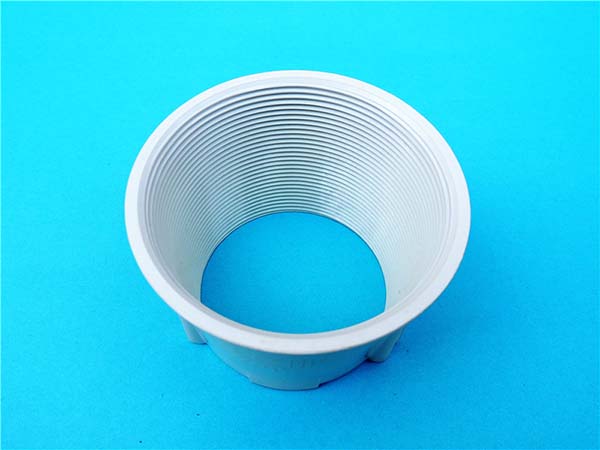

Unlike traditional manufacturing techniques such as injection molding or machining, which often involve removing material from a larger block (subtractive manufacturing) or using molds to shape materials, BAAM builds objects from the ground up. For example, in a typical BAAM process, a digital 3D model of the desired object is sliced into numerous thin cross - sectional layers. A large - scale extrusion system then deposits a continuous bead of thermoplastic material, such as acrylonitrile butadiene styrene (ABS) or polycarbonate, layer by layer, following the precise pattern defined by each cross - section of the 3D model. As the layers accumulate, the final three - dimensional object takes shape. This layer - by - layer construction process allows for the creation of complex geometries that would be extremely difficult, if not impossible, to achieve with traditional manufacturing methods.

Scale and Size Capabilities

One of the most distinguishing features of BAAM is its ability to produce large - scale parts. While traditional 3D printers are often limited to relatively small build volumes, BAAM systems can create objects that are several meters in length, width, and height. For instance, some industrial - grade BAAM printers have build envelopes that can accommodate parts up to 2.5 meters in length, 1.5 meters in width, and 1 meter in height. This makes it an ideal solution for industries such as aerospace, automotive, and architecture, where large - scale components or prototypes are required.

Applications of Big Area Additive Manufacturing

Aerospace Industry

In the aerospace industry, BAAM plays a crucial role. For example, it is used to manufacture engine parts such as turbine blades. Traditional manufacturing methods for these parts are complex and costly. With BAAM, the production process becomes more straightforward. By directly printing turbine blades, manufacturers can reduce the number of individual components that need to be assembled, which in turn reduces the risk of component failure due to joint fatigue. Additionally, BAAM enables the creation of complex internal cooling channels within the blades. These channels are designed to enhance the cooling efficiency of the engine, improving its overall performance. This is a significant advantage as it helps to increase the thrust - to - weight ratio of the engine, which is crucial for aerospace applications. According to industry reports, some aerospace companies have seen a 30% reduction in the weight of certain engine components when using BAAM, while maintaining or even improving their structural integrity.

Automotive Industry

In the automotive sector, BAAM has found diverse applications. One of the key areas is in the production of custom - made automotive parts. Car manufacturers often require parts that are unique to a particular model or a limited - edition series. BAAM allows for the rapid production of these custom parts without the need for expensive molds, as in traditional manufacturing. For instance, a high - end sports car manufacturer might use BAAM to create custom body panels. This not only speeds up the production process but also enables more design flexibility. Designers can experiment with different shapes and structures, knowing that they can be easily produced using BAAM.

Moreover, BAAM is invaluable in the prototype development stage. A new car model typically goes through multiple prototype iterations. With BAAM, automotive engineers can quickly print full - scale prototypes of new car components, such as dashboards or engine mounts. This significantly reduces the time and cost associated with traditional prototype manufacturing methods. A study showed that automotive companies using BAAM for prototype development can cut down the development time by up to 50%, allowing them to bring new models to market faster.

Architecture and Construction

In architecture and construction, BAAM is revolutionizing the way buildings are designed and constructed. It can be used to print large - scale building components. For example, some construction firms have used BAAM to print pre - fabricated wall panels. These panels can be printed with complex patterns and textures, eliminating the need for additional finishing work on - site. They can also be designed to have integrated insulation features, improving the energy efficiency of the building.

BAAM is also useful for creating architectural models. Architects can use BAAM to produce highly detailed, large - scale models of their building designs. These models provide a more accurate representation of the final structure compared to traditional scale models. They can help clients better visualize the proposed building, and also assist architects in identifying design flaws early in the process. Some architectural firms claim that using BAAM - printed models has led to a 30% reduction in design - related changes during the construction phase, saving both time and money.

Yigu Technology's Perspective

As a non - standard plastic metal products custom supplier, Yigu Technology highly values the potential of Big Area Additive Manufacturing (BAAM). BAAM offers a new dimension in custom - made product production. It allows for the creation of unique, complex plastic and metal parts with high precision and efficiency, which is a game - changer in our line of work.

For instance, in the production of large - scale non - standard plastic components, BAAM can significantly reduce the production time compared to traditional manufacturing methods. By eliminating the need for complex molds, we can quickly turn around customized orders, meeting the urgent needs of our clients.

Yigu Technology is also eager to explore cooperation opportunities in the field of BAAM. We believe that by combining our expertise in custom - made products with BAAM technology, we can offer more innovative solutions to our customers. Whether it's for the development of new products or the improvement of existing production processes, BAAM has the potential to enhance our competitiveness and expand our service capabilities.

FAQs about Big Area Additive Manufacturing

What types of materials can be used in big area additive manufacturing?

A variety of materials can be utilized in big area additive manufacturing. Metals such as aluminum alloy, titanium alloy, and stainless steel are popular. Aluminum alloy is lightweight and corrosion - resistant, making it suitable for aerospace and automotive applications where weight reduction is crucial. Titanium alloy offers high strength - to - weight ratio and excellent heat resistance, often used in high - performance engine components. Stainless steel is chosen for its corrosion resistance in applications like marine equipment.

Plastics like acrylonitrile butadiene styrene (ABS), polycarbonate (PC), and polylactic acid (PLA) are also common. ABS is tough and has good dimensional stability, frequently used in prototyping and functional parts. PC has high impact resistance and heat resistance, suitable for applications requiring durability. PLA is a biodegradable plastic, often used in environmentally - friendly projects or in applications where disposal is a concern.

Composites combining different materials can also be used. For example, carbon fiber - reinforced polymers are used to create parts with high strength and stiffness, which are highly valued in the aerospace and high - end sports equipment industries.

How accurate is big area additive manufacturing?

The accuracy of big area additive manufacturing is influenced by multiple factors, including the type of equipment, the material used, and the complexity of the model. Generally, the achievable accuracy ranges from ±0.1 mm to ±1 mm for large - scale prints. In some high - end industrial BAAM systems, the accuracy can reach up to ±0.1 mm under optimal conditions. However, as the size of the printed object increases, the relative accuracy may decrease slightly. For applications in the aerospace industry where tight tolerances are required, such as manufacturing engine parts, the accuracy requirements can be as high as ±0.1 mm or even tighter. In architectural applications, where the focus is more on the overall shape and appearance of large - scale components, an accuracy of ±1 mm may be acceptable.

Is big area additive manufacturing suitable for mass production?

Big area additive manufacturing has both advantages and disadvantages when it comes to mass production. Advantages include high design flexibility, as it can produce complex geometries without the need for expensive molds as in traditional manufacturing. It also allows for on - demand production, reducing inventory costs. For example, if a company needs to produce replacement parts for a large - scale product, BAAM can quickly print them as needed.

However, disadvantages exist. The production speed of BAAM is generally slower compared to traditional mass - production methods like injection molding for simple and high - volume parts. Also, the cost per unit may be higher for mass production, especially considering the cost of materials and equipment.

Overall, BAAM is more suitable for small - to - medium - scale production runs, especially when dealing with complex or customized parts. For example, in the production of custom - designed automotive prototypes or small - batch production of large - scale architectural components, BAAM can offer significant benefits. But for large - scale production of simple, standardized parts, traditional manufacturing methods are often more cost - effective and efficient.