Introduction

In recent years, 3D printing has emerged as a revolutionary technology that is transforming multiple industries. This innovative process, also known as additive manufacturing, creates three - dimensional objects by layering materials based on a digital model. It has been used in everything from creating intricate jewelry pieces to manufacturing aerospace components, offering advantages like reduced material waste, faster production times, and the ability to produce complex geometries that were previously unfeasible with traditional manufacturing methods.

On the other hand, a gas mask, an essential piece of personal protective equipment, serves a crucial role in safeguarding individuals from harmful gases, vapors, dust, and biological agents. Gas masks are widely used in various scenarios, such as industrial settings with chemical hazards, military operations in areas with the threat of chemical warfare, and even during emergency situations like wildfires or chemical spills.

With the growing capabilities of 3D printing and the constant need for effective gas masks, a question arises: Can 3D printing be used to create high - quality gas masks? And if so, what are the implications, advantages, and potential drawbacks? This article will delve into these aspects to help you understand the relationship between 3D printing and gas mask production.

The Basics of 3D Printed Gas Masks

What is 3D Printing?

3D printing, also known as additive manufacturing, is a revolutionary technology that has been transforming the manufacturing landscape in recent years. Instead of subtracting material from a larger block like traditional machining, 3D printing builds objects layer by layer.

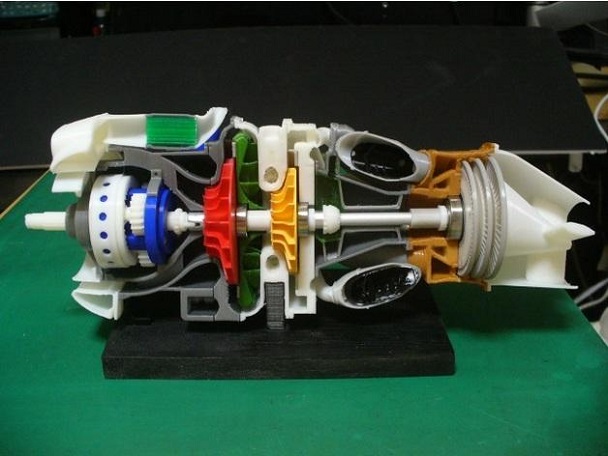

The process begins with a 3D model, which is created using computer - aided design (CAD) software or obtained through 3D scanning. This digital model is then sliced into thin cross - sectional layers by specialized software. A 3D printer reads these sliced files and deposits material, such as plastic filaments in the case of Fused Deposition Modeling (FDM) printers, resin in Stereolithography (SLA) printers, or metal powder in some high - end industrial printers, one layer at a time. As each layer is deposited, it bonds to the previous one, gradually building up the three - dimensional object. For example, in an FDM 3D printer, a heated extruder melts the plastic filament and precisely deposits it onto a build platform, following the pattern defined by the sliced model.

How Do Traditional Gas Masks Work?

Traditional gas masks are designed to protect the wearer's respiratory system and face from harmful substances. They consist of several key components:

- Mask Body: Usually made of rubber or silicone, the mask body forms a tight seal around the face, covering the nose, mouth, and sometimes the eyes. This seal prevents the entry of unfiltered air, ensuring that the only air the wearer breathes is the air that has passed through the filtration system.

- Filter: The filter, often in the form of a canister or cartridge, is the heart of the gas mask. It contains a combination of materials to remove different types of contaminants. For example, activated carbon is commonly used to adsorb organic vapors and certain gases. It has a large surface area with tiny pores that can trap molecules of harmful substances. In addition, filters may also have mechanical filtration layers to capture particles such as dust, pollen, and even biological agents like bacteria and viruses. Some filters are designed with chemical impregnates that can react with specific toxic gases, neutralizing them.

- Valves: Gas masks have two types of valves - an inlet valve and an outlet valve. The inlet valve allows filtered air to enter the mask when the wearer inhales. It is designed to open easily under the slight negative pressure created by inhalation. The outlet valve, on the other hand, opens when the wearer exhales, allowing carbon dioxide and other exhaled gases to escape. This one - way valve system ensures that the air flow within the mask is in the correct direction and that exhaled air does not mix with the incoming filtered air.

Comparison Table: 3D Printed vs Traditional Gas Masks

| Aspect | 3D Printed Gas Masks | Traditional Gas Masks |

| Customizability | High - can be customized to fit an individual's facial features precisely. CAD models can be adjusted to account for unique facial contours, ensuring a better seal. For example, a person with a scarred or deformed face can have a 3D printed gas mask custom - made to fit perfectly. | Low - usually come in standard sizes (small, medium, large). While they may have some adjustable straps, they cannot achieve the same level of personalized fit as 3D printed masks. |

| Cost | Initial setup cost for 3D printing equipment can be high. However, for small - batch production, the per - unit cost can be lower, especially when using affordable 3D printing materials like PLA or ABS plastics. For instance, if you need 10 gas masks, 3D printing can be cost - effective as you don't have to pay for high - volume production molds. | High for small - batch production due to the need for expensive molds and tooling. For large - scale production, the per - unit cost can be reduced, but the initial investment for production setup is substantial. |

| Production Time | Fast - a 3D printed gas mask can be produced within a few hours to a day, depending on the complexity of the design and the type of 3D printer used. A simple 3D printed gas mask shell might take only 3 - 4 hours on a consumer - grade FDM printer. | Slow - traditional manufacturing processes involve multiple steps such as mold making, injection molding, and assembly, which can take days to weeks for production, especially for new designs or when ramping up production. |

| Material Options | Wide range of materials available, including various plastics (PLA, ABS, PETG), and in some cases, even elastomers for a more flexible and skin - friendly fit. Some high - end 3D printers can also work with materials that have added chemical resistance properties. | Limited to materials like rubber and silicone, which are tried - and - tested for gas mask production but may not offer the same level of design flexibility as 3D printable materials. |

| Quality Control | Quality can be highly variable depending on the 3D printer's calibration, the quality of the filament, and the expertise of the operator. However, with proper calibration and monitoring, high - quality prints can be achieved. For example, using a quality - control software to monitor the 3D printing process can help detect and correct any potential issues during printing. | Well - established quality control processes in place due to long - standing manufacturing practices. Manufacturers have strict quality standards for raw materials, production processes, and final product testing. |

Yigu Technology's Perspective

As a non - standard plastic metal products custom supplier, Yigu Technology sees great potential in 3D printed gas masks. The diversity of 3D printing materials allows for the creation of gas masks with complex internal structures that can enhance filtration efficiency. For example, we can use materials with special chemical - resistant properties to better protect against specific harmful substances.

Small - batch customization is also a strong point. With 3D printing, the cost and production cycle for a small number of gas masks are significantly reduced. This is very beneficial for niche markets or emergency needs. However, we also acknowledge the challenges, such as the need to ensure the performance of 3D printed materials meets gas mask standards and strict quality control during production. Close communication with customers is essential to understand their specific requirements and provide the best - suited solutions.

FAQ

Q1: Is a 3D printed gas mask as safe as a traditional one?

A 3D printed gas mask can be as safe as a traditional one if the materials used and the design meet the required safety standards. For example, the material should have the proper chemical resistance and the structural integrity to maintain a tight seal. However, quality control can be more challenging with 3D printed masks. Issues like inconsistent layer adhesion in 3D printing could potentially compromise the mask's performance. But with proper calibration of the 3D printer and quality - control measures during the printing process, 3D printed gas masks can offer reliable protection.

Q2: What materials can be used for 3D printing gas masks?

Common materials for 3D printing gas masks include PLA (Polylactic Acid), which is biodegradable, easy to print with, and has some resistance to moisture. ABS (Acrylonitrile Butadiene Styrene) is another option; it is more durable and has better heat resistance compared to PLA, making it suitable for more demanding environments. PETG (Polyethylene Terephthalate Glycol - modified) is also popular as it has good impact resistance and is more flexible than PLA, providing a more comfortable fit around the face. Some advanced materials with added chemical - resistant properties are also being explored for specialized gas mask applications.

Q3: Can I 3D print a gas mask at home?

While it is technically possible to 3D print a gas mask at home, it is not recommended. Firstly, ensuring that the 3D printed material meets the safety and filtration requirements for a gas mask can be difficult. Home - grade 3D printers may not produce a high - enough quality print to guarantee a proper seal. Additionally, gas masks need to meet strict safety and quality certifications, which are very hard to achieve with home - printed masks. It's best to rely on professionally made and certified gas masks for situations where your safety depends on it.