Introduction

In recent years, 3D metal printing has emerged as a revolutionary technology with applications spanning across multiple industries, from aerospace and automotive to healthcare and jewelry making. This innovative manufacturing process allows for the creation of complex metal parts directly from digital designs, offering numerous advantages such as design freedom, reduced material waste, and faster production times for prototypes and small - batch production.

For instance, in the aerospace industry, 3D metal - printed components are being used to create lighter and more fuel - efficient engines. In healthcare, customized implants can be produced to fit individual patients perfectly. However, one of the most frequently asked questions and a significant factor that often influences its widespread adoption is: What is the cost of 3D metal printing? The cost of 3D metal printing is a multi - faceted issue, influenced by various elements including the type of 3D printing technology used, the materials involved, the complexity of the design, and post - processing requirements. Understanding these cost components is crucial for businesses and individuals considering 3D metal printing services, as it can help in making informed decisions about whether this technology is a viable option for their specific needs.

Factors Affecting 3D Metal Printing Cost

Material Costs

The materials used in 3D metal printing play a significant role in determining the overall cost. Common materials include aluminum alloys, titanium alloys, stainless steel, and cobalt - chrome alloys. For example, the price of aluminum alloy powder for 3D printing is relatively lower, ranging from approximately \(50 - \)150 per kilogram. In contrast, titanium alloy powder, known for its high strength - to - weight ratio and excellent corrosion resistance, is much more expensive, with prices typically ranging from \(1,500 - \)3,000 per kilogram. The price variance is due to factors such as the complexity of the material production process, the rarity of raw materials, and the level of processing required to produce the fine - grained powders suitable for 3D printing.

Equipment Costs

The cost of 3D metal printers can vary widely. Desktop - sized 3D metal printers, which are more suitable for small - scale prototyping and hobbyist use, can cost anywhere from \(10,000 to \)50,000. Industrial - grade 3D metal printers, with larger build volumes, higher precision, and more advanced features, are significantly more expensive, often ranging from \(100,000 to over \)1 million. For instance, some high - end printers used in aerospace manufacturing, which need to meet strict quality and precision standards, can cost several million dollars. Additionally, the cost of equipment maintenance, including regular servicing, replacement of parts like lasers (in laser - based 3D printing technologies), and software upgrades, should also be factored in. Maintenance costs can amount to 10 - 20% of the initial equipment cost per year.

Labor Costs

Labor costs in 3D metal printing are related to the skills and time required for the process. Designing a 3D model suitable for metal printing can be time - consuming, especially if it involves complex geometries or requires optimization for the 3D printing process. A simple, straightforward model might take a few hours of a designer's time, while a highly intricate and customized model could take days or even weeks. The hourly rate for a skilled 3D model designer can range from \(30 - \)100, depending on their experience and the region. Operating the 3D printing equipment also requires trained personnel. In industrial settings, operators may need to be familiar with safety protocols, equipment calibration, and basic troubleshooting, and their salaries contribute to the overall labor cost.

Printing Complexity

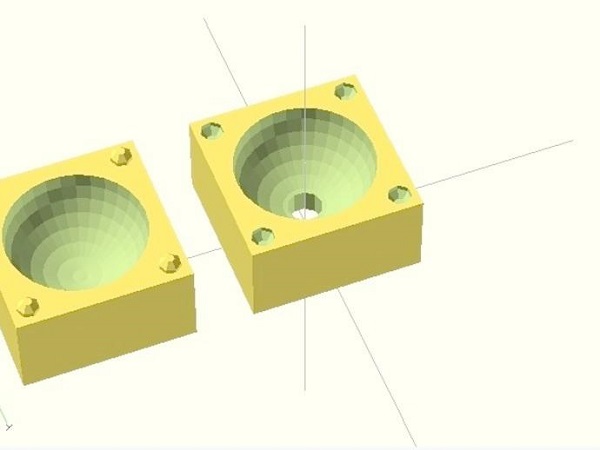

The complexity of the 3D - printed object has a direct impact on the cost. A simple, solid - shaped metal part with basic dimensions and no internal structures can be printed relatively quickly and at a lower cost. For example, a small, cube - shaped aluminum part might cost only a few dollars in material and a short printing time, resulting in a total cost of around \(10 - \)20, depending on the printer used. However, a complex part with internal lattice structures, thin walls, and high - precision features, such as a turbine blade for an aircraft engine, will be much more expensive. The complex geometry may require more support structures during printing, longer printing times to ensure precision, and potentially more post - processing steps. Such a part could cost hundreds or even thousands of dollars, considering the additional material usage for supports, the extended printing time, and the more elaborate post - processing procedures.

Cost Comparison with Traditional Manufacturing

When considering 3D metal printing, it's essential to compare its costs with traditional manufacturing methods, such as machining, casting, and forging. The following table provides a general cost comparison between 3D metal printing and traditional manufacturing for different production volumes:

| Production Volume | 3D Metal Printing Cost | Traditional Manufacturing Cost |

| Small - batch (1 - 100 units) | Lower cost for complex designs. For example, for a complex titanium alloy component, 3D metal printing might cost \(500 - \)1,500 per unit. This is because there is no need for expensive custom tooling, and the design can be directly translated into a physical part. | High cost for complex designs due to tooling costs. For casting a complex part, the initial tooling cost can be \(5,000 - \)10,000, and the per - unit cost might be \(800 - \)2,000 when accounting for tooling amortization over a small batch. |

| Large - batch (1000+ units) | Higher per - unit cost compared to traditional manufacturing. As the volume increases, the cost per unit in 3D printing doesn't decrease as significantly as in traditional methods. For a large - scale production of a simple aluminum part, 3D printing could cost \(100 - \)200 per unit. | Lower per - unit cost with economies of scale. In mass production through forging, the per - unit cost of a simple aluminum part can be reduced to \(20 - \)50, especially when high - volume production allows for more efficient use of resources and lower tooling cost per unit. |

In small - batch production, 3D metal printing often has a cost advantage, especially for complex designs. Traditional manufacturing methods require the creation of molds, dies, or fixtures, which can be very expensive for small production runs. 3D printing eliminates the need for most of these upfront tooling costs, making it a more cost - effective option. However, for large - batch production, traditional manufacturing methods usually become more cost - efficient due to economies of scale. The cost per unit in traditional manufacturing can be significantly reduced as production volume increases, while 3D printing costs are more affected by factors like material usage and printing time per part, which don't decrease proportionally with higher volumes.

Yigu Technology's View

As a non - standard plastic metal products custom supplier, Yigu Technology understands the significance of cost - effective 3D metal printing. We have extensive experience in controlling costs during the 3D metal printing process for customized products.

Firstly, we have established long - term partnerships with reliable material suppliers. This enables us to obtain high - quality metal powders at more favorable prices, effectively reducing material costs without sacrificing quality. For example, when printing non - standard plastic - metal composite parts, we carefully select materials based on the product's performance requirements, choosing the most cost - effective option from a range of available alloys.

Secondly, our team of skilled technicians is proficient in optimizing 3D models. By reducing unnecessary complexity in the design while maintaining the product's functionality, we can shorten printing times and minimize the need for excessive support structures, thus cutting down on both labor and material costs.

In conclusion, at Yigu Technology, we believe that with proper material sourcing, design optimization, and efficient production management, 3D metal printing can be a cost - effective solution even for non - standard and customized plastic metal products.

FAQ

Q1: Is 3D metal printing always more expensive than traditional manufacturing?

Not always. For small - batch production and complex designs, 3D metal printing can be more cost - effective as it eliminates high tooling costs associated with traditional methods. However, for large - scale production of simple parts, traditional manufacturing often has a lower per - unit cost due to economies of scale.

Q2: How can I accurately estimate the cost of 3D metal printing a part?

You need to consider multiple factors, such as the type of metal material, the complexity of the 3D model, the 3D printing process used, and post - processing requirements. You can consult professional 3D printing service providers, who can offer more accurate cost estimates based on your specific design. Additionally, some online cost - estimating tools are available, which can provide a rough estimate by inputting basic parameters of your part.

Yes, there can be hidden costs. Equipment maintenance, including regular servicing, replacement of key components, and software updates, adds to the overall cost. Post - processing steps like heat treatment, surface finishing, and support structure removal also contribute to the final cost and are sometimes overlooked during initial cost calculations.