Introduction

Definition and Basics of 3D Printing

In mechanical engineering, 3D printing, also known as additive manufacturing, is a revolutionary technology that creates three - dimensional objects from a digital model. It works by adding material layer by layer, in contrast to traditional subtractive manufacturing methods like milling or carving which remove material from a larger block.

The process begins with a 3D model, typically created using computer - aided design (CAD) software or obtained from a 3D scanner. This digital model is then sliced into thin cross - sectional layers by specialized software. The 3D printer reads these sliced files and deposits the material, such as plastic, metal, ceramic, or composite materials, in precise patterns according to the design of each layer. As the layers are built upon one another, the final three - dimensional object gradually takes shape. For example, in fused deposition modeling (FDM), one of the most common 3D printing techniques, a spool of thermoplastic filament is melted and extruded through a nozzle to create each layer.

Significance in Mechanical Engineering

3D printing has brought about a paradigm shift in mechanical engineering. It serves as a powerful catalyst for innovation. Designers are no longer constrained by the limitations of traditional manufacturing processes. They can now create complex geometries and structures that were previously impossible or extremely difficult to produce. For instance, lattice structures, which are lightweight yet strong, can be easily 3D - printed for applications in aerospace components, where weight reduction is crucial for fuel efficiency.

In terms of efficiency, 3D printing significantly reduces the time and cost associated with prototyping. In the past, creating a prototype often required multiple steps, including machining, casting, and assembly, which could take weeks or even months. With 3D printing, a prototype can be produced in a matter of hours or days. This allows mechanical engineers to quickly test and iterate on their designs, accelerating the product development cycle.

Moreover, 3D printing enables on - demand manufacturing. Instead of mass - producing parts and storing them in warehouses, companies can print parts as needed. This reduces inventory costs and waste, making the manufacturing process more sustainable. Overall, 3D printing has become an indispensable tool in modern mechanical engineering, driving advancements in various sub - fields such as automotive, aerospace, and robotics.

Applications of 3D Printing in Mechanical Engineering

Prototyping

One of the most prominent applications of 3D printing in mechanical engineering is in prototyping. In the past, creating a prototype for a mechanical product often involved multiple complex processes such as machining, casting, and assembly. For example, in the automotive industry, before the advent of 3D printing, developing a new car prototype could take months. Engineers had to first create molds, then cast parts from various metals or plastics, and finally assemble them together. This process was not only time - consuming but also costly, with high material waste.

However, 3D printing has revolutionized this process. By simply inputting a 3D model into the printer, a physical prototype can be produced within hours or days. For instance, a small - scale automotive parts manufacturer can use 3D printing to quickly produce a prototype of a new engine component. This allows them to test the form, fit, and function of the part much earlier in the design cycle. In the aerospace industry, companies like Boom Supersonic use 3D printing to build prototypes of their supersonic aircraft components. This enables them to iterate on their designs rapidly, reducing the overall development time and cost.

Custom Parts Manufacturing

3D printing also shines in custom parts manufacturing. In many industries, there is a growing need for personalized components that are tailored to specific requirements. In the medical field, for example, prosthetics can now be 3D - printed to fit the unique anatomy of each patient. A patient with an amputated limb can have a prosthetic limb custom - made using 3D scanning and printing technology. The scanned data of the residual limb is used to create a 3D model, which is then printed into a prosthetic that provides a more comfortable and precise fit compared to traditional, mass - produced prosthetics.

In mechanical manufacturing, custom - made parts for specialized machinery are also becoming more common. A small - scale industrial equipment manufacturer might need a unique gear or a connector for a one - of - a - kind machine they are building. Instead of going through the expensive and time - consuming process of traditional manufacturing, they can use 3D printing to produce the part exactly as needed. This not only meets the specific needs of the equipment but also reduces inventory costs, as parts are printed on - demand rather than stocked in large quantities.

Complex Geometric Structures

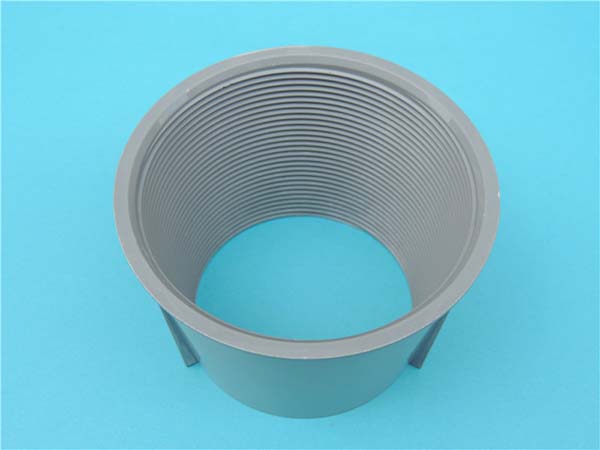

The ability to create complex geometric structures is another major advantage of 3D printing in mechanical engineering. Traditional manufacturing methods often struggle to produce parts with intricate internal channels, lattice structures, or non - standard shapes. For example, in the production of engine components, such as turbine blades, traditional machining methods are limited in creating the complex cooling channels inside the blades. These cooling channels are crucial for maintaining the performance and durability of the engine under high - temperature conditions.

With 3D printing, these complex structures can be fabricated with relative ease. In the manufacturing of mechanical molds, 3D printing allows for the creation of molds with complex cavities and undercuts. This enables the production of parts with complex outer shapes that were previously difficult or impossible to manufacture. A study showed that 3D - printed parts with complex geometries can reduce weight by up to 40% compared to their traditionally - manufactured counterparts while maintaining the same or even better mechanical properties, as seen in the aerospace components where weight reduction is critical for fuel efficiency and performance.

Yigu Technology's View

As a non - standard plastic and metal products custom supplier, Yigu Technology recognizes the profound impact of 3D printing in mechanical engineering. In custom production, 3D printing enables us to create highly personalized parts with complex geometries that meet the unique needs of our clients. For example, when manufacturing non - standard plastic components for a special - purpose mechanical device, 3D printing allows us to quickly turn the design into a physical product, reducing the lead time significantly compared to traditional manufacturing methods.

However, Yigu Technology also acknowledges the challenges. The high cost of 3D printing equipment and materials, especially for high - performance metals, can be a barrier. Moreover, the relatively slow printing speed and limited size of printed parts can be constraints for large - scale production. Despite these challenges, the opportunities are vast. With the continuous development of 3D printing technology, we anticipate more cost - effective solutions and the ability to serve a wider range of industries with even more complex and customized products.

FAQ

What are the most suitable materials for 3D printing in mechanical engineering?

In mechanical engineering, several materials are highly suitable for 3D printing. Metals like titanium, aluminum, and stainless steel are popular. Titanium offers excellent strength - to - weight ratio and high corrosion resistance, making it ideal for aerospace and medical implants. Aluminum is lightweight and has good thermal conductivity, suitable for heat - sink applications in electronics. Stainless steel provides high strength and durability, often used in industrial machinery parts. Plastics such as ABS (acrylonitrile - butadiene - styrene) are common. ABS is tough, heat - resistant to a certain extent, and easy to print, making it great for functional prototypes. PLA (polylactic acid) is another widely used plastic. It is biodegradable, has good dimensional stability, and is suitable for consumer products and small - scale mechanical parts. Additionally, composite materials that combine the properties of different substances are emerging as suitable 3D - printing materials, offering enhanced mechanical properties.

How to ensure the accuracy and quality of 3D - printed parts?

To ensure the accuracy and quality of 3D - printed parts, several steps can be taken. Optimizing print parameters is crucial. This includes adjusting the layer height, printing speed, and temperature. For example, a smaller layer height generally results in a smoother surface finish and higher accuracy but may increase printing time. The right printing speed should be selected to prevent issues like under - extrusion or over - extrusion, which can affect the shape and strength of the part. Temperature control is essential, especially for materials like plastics, as incorrect temperatures can lead to warping or poor adhesion between layers. Post - processing also plays a significant role. Sanding can be used to smooth rough surfaces, while polishing can enhance the surface finish. Heat - treating metal parts can improve their mechanical properties and dimensional stability. Additionally, using high - quality 3D printers with accurate motion systems and calibration regularly can help maintain the accuracy of the printed parts.

Can 3D printing completely replace traditional manufacturing methods in mechanical engineering?

3D printing cannot completely replace traditional manufacturing methods in mechanical engineering. While 3D printing offers unique advantages such as the ability to create complex geometries and rapid prototyping, traditional methods still have their own strengths. For mass production, traditional manufacturing methods like injection molding and stamping are often more cost - effective. They can produce large quantities of parts quickly and at a lower cost per unit compared to 3D printing, which is relatively slow and has higher material costs for large - scale production. In terms of material properties, some traditional manufacturing processes can achieve better material density and mechanical properties in certain materials. For example, forged metal parts often have superior strength and fatigue resistance compared to 3D - printed metal parts in some applications. In most cases, 3D printing and traditional manufacturing methods complement each other. 3D printing can be used for prototyping, custom - part production, and small - batch manufacturing, while traditional methods are more suitable for large - scale production and applications where specific material properties are critical.