What is a 3D Printed RC Glider?

A 3D printed RC glider combines the precision and flexibility of 3D printing technology with the thrill of remote - controlled gliding.

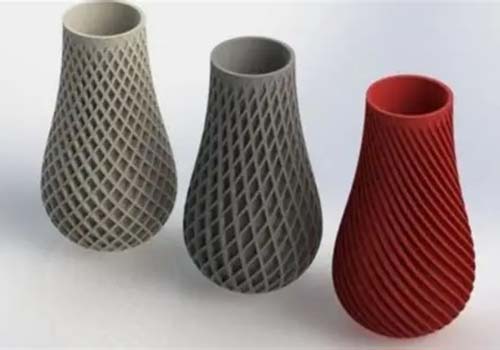

The 3D Printing Aspect

3D printing, also known as additive manufacturing, is a process of creating three - dimensional objects from a digital file. For a 3D printed RC glider, designers first use computer - aided design (CAD) software to create a detailed 3D model of the glider. This model includes every part of the glider, from the main wing and fuselage to the tail fins. The 3D printer then reads the digital model and builds the glider layer by layer. Common 3D printing materials for RC gliders are lightweight plastics like PLA (Polylactic Acid) or ABS (Acrylonitrile Butadiene Styrene). PLA is popular due to its eco - friendliness, ease of printing, and relatively low cost, while ABS offers more durability and heat resistance.

The RC Glider Aspect

An RC glider is a type of model aircraft that doesn't have an onboard power - generating engine like a motor. Instead, it relies on external forces such as gravity, thermals (rising columns of warm air), and the skill of the remote - control operator to stay aloft. RC gliders are equipped with a receiver that picks up signals from a remote control held by the operator. These signals control the movement of the control surfaces on the glider, such as the ailerons (which control roll), the elevator (which controls pitch), and the rudder (which controls yaw).

Combining 3D printing with RC gliders offers several advantages. For example, 3D printing allows for highly customized designs. Hobbyists can modify the shape of the wing, the size of the fuselage, or the placement of the control surfaces to optimize the glider's performance for different flying conditions. Traditional manufacturing methods for RC gliders often have limitations in terms of design complexity and customization, but 3D printing breaks through these barriers.

3D Printed RC Glider vs Traditional Gliders

When considering an RC glider, it's essential to understand how 3D printed versions stack up against traditional ones. Here's a comparison:

| Aspect | 3D Printed RC Glider | Traditional Glider |

| Production Process | Created through 3D printing, where a digital model is built layer - by - layer. This allows for rapid prototyping and easy design changes. For example, if you want to modify the shape of the wing, you can simply adjust the CAD model and print a new part within hours. | Typically involves more complex manufacturing processes such as molding, cutting, and assembling of pre - made parts. Making design changes often requires creating new molds or cutting templates, which can be time - consuming and expensive. |

| Cost | Lower upfront costs for small - scale production. A 3D printer can cost anywhere from a few hundred to a few thousand dollars, and the cost of filament (printing material) is relatively low. For instance, a spool of PLA filament, which can be used to print multiple glider parts, might cost around \(20 - \)30. However, high - end 3D printers for more precise and industrial - grade prints can be costly. | High initial investment for tooling and molds. If a manufacturer wants to produce a new model of a traditional glider, they need to invest in creating molds, which can cost tens of thousands of dollars. The cost per unit can be high, especially for low - volume production runs. |

| Performance | Performance can be highly optimized through custom design. For example, by using computational fluid dynamics (CFD) simulations in the CAD design stage, hobbyists can design wings with unique airfoil shapes that can potentially improve lift - to - drag ratios. Some 3D printed gliders have shown excellent performance in local RC gliding competitions, with reported flight times of up to 30 minutes in thermic conditions. | Performance is often based on tried - and - true designs. Traditional gliders have well - established designs that have been optimized over years. They generally offer consistent performance, but it's more challenging to make radical performance - enhancing design changes without significant R&D investment. |

| Customization | Highly customizable. You can adjust the size, shape, and even the internal structure of the glider according to your specific needs. For example, you can design a glider with a larger payload bay for carrying small cameras or sensors, or create a glider with a unique wingspan for different flying conditions. | Limited customization. While some adjustments can be made, the overall design is restricted by the molds and manufacturing processes. Customizing a traditional glider often involves significant manual labor and may not be as precise as 3D printed customization. |

Yigu Technology's View

As a non - standard plastic metal products custom supplier, Yigu Technology sees great potential in 3D printed RC gliders. In terms of materials, we understand the importance of choosing the right substances for optimal performance. Our extensive experience in dealing with various plastics and metals allows us to recommend materials that can enhance the strength - to - weight ratio of the glider. For example, we can suggest advanced composite plastics that offer both the lightweight property required for gliding and the durability to withstand flight stresses.

Regarding customization services, we can provide precise manufacturing according to specific design requirements. Whether it's a unique airfoil shape designed by the customer or a custom - sized fuselage, our high - precision manufacturing equipment can bring these ideas to life. We also offer post - processing services such as surface treatment to improve the aesthetics and corrosion resistance of 3D printed RC gliders. With our support, hobbyists and designers can focus more on the creative design of their gliders, while we take care of the material selection and manufacturing precision issues.

FAQs

Q1: Is a 3D printed RC glider suitable for beginners?

A 3D printed RC glider can be suitable for beginners in many aspects. In terms of operation, many 3D printed gliders are designed with relatively simple control mechanisms, similar to traditional RC gliders. They usually operate on basic principles of controlling ailerons, elevator, and rudder, which can be learned through practice. In terms of price, 3D printed gliders can be cost - effective. As mentioned before, the cost of 3D printing materials like PLA filament is relatively low, and with a 3D printer, hobbyists can produce their own gliders at a fraction of the cost of buying a pre - made traditional glider. However, they can be more fragile compared to some high - end traditional gliders made of more durable materials. But with proper care and some basic knowledge of 3D printing and glider assembly, beginners can still enjoy flying a 3D printed RC glider.

Q2: How can I improve the flight performance of my 3D printed RC glider?

There are several ways to enhance the flight performance. First, adjust the center of gravity. A well - balanced glider is crucial. You can add or remove small weights at different parts of the glider (such as the nose or the tail) to ensure it has the correct balance. Second, optimize the wing angle. A proper angle of attack can increase lift. You can experiment with different wing angles through trial - and - error or by referring to aerodynamic principles. For example, a slightly increased angle might provide more lift during take - off but could also increase drag, so it's about finding the right balance. Finally, choose a suitable flying site. A large, open area with consistent wind conditions (like a grassy field away from strong winds or turbulence near buildings) can greatly improve the glider's flight performance.

Q3: What materials are commonly used for 3D printed RC gliders?

Common materials include PLA (Polylactic Acid) and ABS (Acrylonitrile Butadiene Styrene). PLA is popular because it is easy to print, has a relatively low melting point, and is eco - friendly. It is lightweight, which is beneficial for the glider as it reduces the overall weight and thus improves the glide ratio. However, it is less heat - resistant and not as durable as some other materials. ABS, on the other hand, offers better heat resistance and durability. It can withstand more stress during flight, making it suitable for gliders that may encounter harsher conditions. But it is a bit heavier than PLA and requires a higher printing temperature, which might be a consideration depending on your 3D printer.