Understanding Extrusion Prototyping

Extrusion prototyping, also known as material extrusion, is a fundamental additive manufacturing technique that has revolutionized the way three - dimensional (3D) objects are created. This method involves the continuous extrusion of a material through a nozzle or an orifice, layer by layer, to build up a 3D structure.

The process begins with a spool of filament - like material, which can be made of various substances such as thermoplastics (like PLA, ABS), elastomers, or even some composite materials. This filament is fed into an extrusion head, where it is heated to its melting point. Once molten, the material is pushed through a small - diameter nozzle. The nozzle moves in a programmed path, depositing the melted material precisely onto a build platform. As each layer is laid down, it adheres to the previous one, and over time, the complete 3D object takes shape.

For example, in a typical desktop 3D printer using extrusion prototyping, a PLA filament might be used. The printer's software slices a 3D model of the desired object into hundreds or even thousands of thin horizontal layers. The extrusion head then moves in an X - Y plane according to the coordinates of each layer, extruding the melted PLA. After one layer is completed, the build platform lowers slightly, and the next layer is deposited on top. This sequential layering process continues until the entire object is fabricated.

One of the key advantages of extrusion prototyping is its relative simplicity and cost - effectiveness. Desktop 3D printers based on this technology are widely available and affordable, making it accessible for hobbyists, students, and small - scale businesses. Additionally, the range of available materials allows for a high degree of customization. Different materials have unique properties such as strength, flexibility, and heat resistance, enabling the creation of prototypes suitable for various applications.

The Process in Detail

Material Selection

The choice of materials in extrusion prototyping is crucial as it directly impacts the properties of the final product. Some common materials suitable for extrusion prototyping are as follows:

- Polylactic Acid (PLA): This is a biodegradable thermoplastic derived from renewable resources like corn starch or sugarcane. PLA has a relatively low melting point, usually around 180 - 220°C, which makes it easy to extrude. It is popular for hobbyist and educational applications due to its ease of use, pleasant smell during printing, and a wide range of available colors. It is often used for creating decorative items, small household products, and simple prototypes where strength requirements are not extremely high.

- Acrylonitrile Butadiene Styrene (ABS): ABS is a strong and durable thermoplastic. It has a higher melting point than PLA, typically around 220 - 260°C. ABS is known for its good impact resistance, which makes it suitable for applications where the prototype may be subject to mechanical stress, such as in the automotive or electronics industries for creating parts like housings or brackets. However, it has a stronger odor during printing and requires a heated build platform to prevent warping.

- Thermoplastic Polyurethane (TPU): TPU is an elastomeric material, which means it has high elasticity and flexibility. It can be stretched and return to its original shape. This makes it ideal for applications that require flexibility, such as creating flexible joints, gaskets, or shoe soles. The extrusion process for TPU requires careful temperature control as it has a different viscosity compared to rigid thermoplastics.

Step - by - Step Procedure

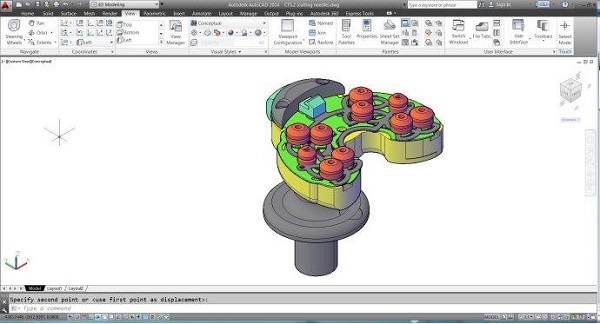

- 3D Model Creation: The first step is to create a 3D model of the desired object. This can be done using computer - aided design (CAD) software. For example, professionals might use Autodesk Inventor, while hobbyists could use more accessible options like Tinkercad. The 3D model serves as the digital blueprint for the physical object.

- Slicing: Once the 3D model is ready, it needs to be sliced into thin layers. Specialized slicing software, such as Cura or PrusaSlicer, is used for this purpose. The slicing process divides the 3D model into hundreds or thousands of horizontal layers, each with a specific thickness (usually ranging from 0.1 mm to 0.4 mm, depending on the desired print quality). During this step, the software also generates the toolpath that the extrusion head will follow.

- Extrusion: The filament material is fed into the extrusion head, which heats it to its melting point. As the extrusion head moves according to the toolpath generated in the slicing step, it extrudes the melted material through a nozzle. For instance, in a desktop 3D printer, the nozzle diameter is often around 0.4 mm. The melted material is deposited onto the build platform, adhering to the previously laid layers.

- Layering and Bonding: Each layer is carefully deposited on top of the previous one. The heat from the extruded material helps it bond to the underlying layer. As the layers stack up, the object gradually takes shape. The speed at which the extrusion head moves, the extrusion temperature, and the flow rate of the material all need to be precisely controlled to ensure proper bonding between layers and accurate dimensional accuracy.

- Support Structure Removal (if applicable): For complex geometries that have overhangs or bridging features, support structures may be generated during the slicing process. These support structures are made of the same or a different material (such as a water - soluble material in some cases). After the printing is complete, these support structures need to be removed carefully to reveal the final, clean - looking prototype.

Applications Across Industries

Extrusion prototyping has found its way into numerous industries, revolutionizing the way products are designed, developed, and produced. Here are some of the key applications across different sectors:

Manufacturing

In the manufacturing industry, extrusion prototyping plays a crucial role in rapid prototype creation and the production of custom - made parts. For example, a small - scale automotive parts manufacturer wanted to develop a new design for an engine bracket. Using extrusion prototyping with ABS material, they were able to quickly create a prototype of the bracket. This allowed them to test the fit and functionality of the part within the engine compartment without investing in expensive tooling for traditional manufacturing methods. The process saved them significant time and cost in the product development phase. In another case, a consumer electronics company used extrusion prototyping to produce custom - designed housings for a new line of smart home devices. By using PLA filaments in the extrusion process, they could create multiple design iterations, evaluating factors such as ergonomics and aesthetics before finalizing the design for mass production.

Healthcare

The healthcare sector has also seen significant benefits from extrusion prototyping. One of the most remarkable applications is in the production of custom - made prosthetics. Consider a patient who has lost a limb and requires a prosthetic device. Extrusion prototyping enables the creation of a prosthetic limb that is tailored to the individual's specific body shape and needs. Using 3D scanning technology, the patient's residual limb is scanned, and a 3D model is created. This model is then used to print a custom - fit prosthetic socket using materials like TPU for its flexibility and comfort. Additionally, medical models are also being produced through extrusion prototyping. For instance, medical students can use 3D - printed models of organs, such as hearts or kidneys, made from biocompatible materials, to study the anatomy in a more hands - on way. These models can accurately represent the shape, size, and internal structures of the organs, enhancing the learning experience.

Architecture and Design

In architecture and design, extrusion prototyping serves as an invaluable tool for building model creation and design concept validation. Architects often use it to create scale models of buildings. For a large - scale commercial building project, an architect can use extrusion prototyping to build a detailed model of the building facade, complete with accurate representations of windows, balconies, and other architectural features. This allows the client to visualize the final appearance of the building before construction begins. Designers can also use extrusion prototyping to test design concepts. For example, a furniture designer can create a 3D - printed prototype of a new chair design, experimenting with different shapes and materials to optimize comfort and aesthetics. The ability to quickly iterate on designs using extrusion prototyping speeds up the design process and helps in bringing innovative designs to the market faster.

Yigu Technology's Viewpoint

As a non - standard plastic metal products custom supplier, Yigu Technology highly values extrusion prototyping. This technology plays a crucial role in our custom production process. It allows us to meet diverse customization needs with ease. For instance, when clients have unique design requirements for plastic or metal components, extrusion prototyping enables us to quickly transform their ideas into physical prototypes.

In small - batch production, extrusion prototyping offers significant advantages. The relatively low - cost setup and quick turnaround time make it a cost - effective solution. We can produce small quantities of high - quality custom parts without the need for large - scale production equipment and expensive tooling. This not only reduces production costs but also shortens the lead time, allowing our clients to bring their products to market faster.

FAQ

What types of materials are commonly used in extrusion prototyping?

Common materials for extrusion prototyping include Polylactic Acid (PLA), which is biodegradable and easy to extrude with a melting point around 180 - 220°C, popular for hobbyist and educational uses. Acrylonitrile Butadiene Styrene (ABS) is strong and durable, with a melting point of 220 - 260°C, suitable for parts under mechanical stress. Thermoplastic Polyurethane (TPU) is an elastomeric material, great for applications needing flexibility like gaskets or shoe soles.

How accurate is extrusion prototyping?

The accuracy of extrusion prototyping typically ranges from ±0.1 mm to ±0.4 mm. However, this can be affected by several factors. The quality of the 3D printer, such as the precision of its mechanical components like the stepper motors and the lead screws, plays a significant role. Additionally, the material properties, like its viscosity and shrinkage rate during cooling, can impact accuracy. Printing speed and temperature settings also influence how precisely the layers are deposited and bonded, thus affecting the overall accuracy of the final prototype.

Can extrusion prototyping be used for large - scale production?

Extrusion prototyping has some limitations for large - scale production. While it's great for rapid prototyping and small - batch production due to its relatively low - cost setup and quick turnaround, for large - scale production, the slow printing speed can be a major drawback. Also, maintaining consistent quality across a large number of prints can be challenging. However, in some cases where customization is key and production volumes are not extremely high, extrusion prototyping can still be a viable option for large - scale production, especially when combined with other manufacturing techniques.