1. Understanding the Basics of Silicone Prototypes

Silicone prototypes play a pivotal role in the product development cycle. They are the preliminary models crafted to test the design, functionality, and feasibility of a final product made from silicone. This stage is crucial as it allows manufacturers and designers to identify and rectify potential issues before mass production, saving both time and cost.

1.1 Applications in Diverse Industries

- Medical Industry: Silicone is highly biocompatible, making it an ideal material for medical prototypes. It is used in creating items like catheters, prosthetics, and surgical tools. For instance, in the production of prosthetics, silicone prototypes enable manufacturers to ensure a perfect fit and comfort for the user. A study by the Medical Device Manufacturers Association showed that over 70% of new medical device concepts start with silicone prototypes to validate design and functionality.

- Automotive Industry: In the automotive sector, silicone prototypes are used for manufacturing gaskets, seals, and interior components. These prototypes help in testing the durability and performance of parts under various conditions, such as extreme temperatures and high - pressure environments. According to industry reports, around 30% of automotive parts undergo prototype testing using silicone before full - scale production.

- Electronics Industry: With the miniaturization and high - performance requirements of electronic devices, silicone prototypes are used for making components like insulators, connectors, and heat - dissipating parts. Their excellent electrical insulation and heat - resistance properties make them suitable for this industry. For example, in smartphone manufacturing, silicone prototypes are used to design and test the rubberized buttons and seals to ensure water - resistance and long - term usability.

2. Key Aspects to Evaluate Silicone Prototype Manufacturers

2.1 Experience and Track Record

When evaluating silicone prototype manufacturers, experience is a fundamental factor. Look at how long they have been operating in the industry: a company with a decade - long presence is likely to have encountered and overcome various challenges, from complex design requirements to tight production schedules. For example, a manufacturer that has been in business for 15 years has had the opportunity to adapt to technological advancements and changing market demands.

The number of completed projects also speaks volumes: a high - volume producer, having completed over 500 projects in a year, indicates their ability to handle a diverse range of tasks. Additionally, customer reviews and testimonials are invaluable. A manufacturer with an average rating of 4.8 out of 5 on review platforms, based on 100+ reviews, is likely to provide reliable services.

2.2 Manufacturing Capabilities

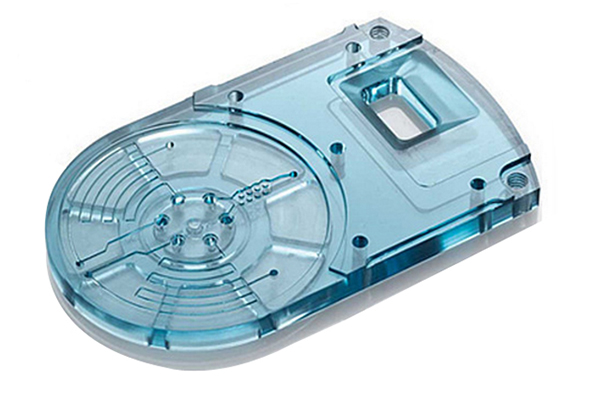

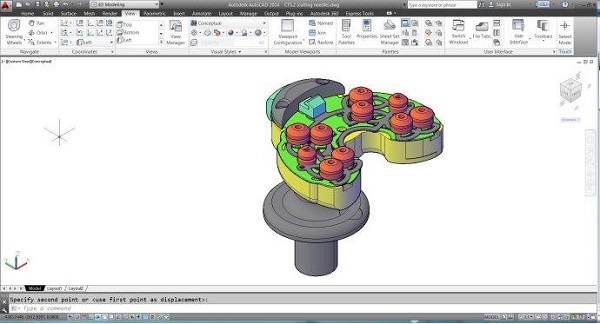

Advanced equipment is the backbone of a capable silicone prototype manufacturer. They should be equipped with state - of - the - art injection molding machines, 3D printers, and precision measuring tools. For instance, high - speed injection molding machines can significantly reduce production time, while 3D printers enable the creation of complex geometries with ease.

Regarding molding processes, manufacturers should be proficient in multiple techniques. Liquid Silicone Rubber (LSR) molding is ideal for producing parts with high precision and soft - touch surfaces, often used in medical and consumer electronics applications. Solid Silicone Rubber (SSR) molding, on the other hand, is suitable for larger and more robust components. A manufacturer that offers both processes can meet a wider range of customer needs. High - precision 加工能力也是关键。能够达到 ±0.01mm 公差的制造商可以确保产品的精确配合和功能。

2.3 Material Selection and Quality Control

The right material selection is crucial for the success of a silicone prototype. Different silicone grades have varying properties, such as hardness, temperature resistance, and chemical resistance. For a prototype intended for use in a high - temperature industrial environment, a high - temperature - resistant silicone material with a maximum operating temperature of 250°C would be appropriate.

Quality control is non - negotiable: manufacturers should conduct material testing to ensure that the silicone meets the required standards. This includes tests for tensile strength, elongation, and compression set. During the production process, continuous monitoring should be in place, with inspections at key stages. For example, in injection molding, checking the mold filling and part ejection regularly. Final product inspection should involve a comprehensive check, including visual inspection for surface defects, dimensional inspection using coordinate measuring machines (CMMs), and functional testing to ensure the prototype performs as expected.

2.4 Design and Engineering Support

A good silicone prototype manufacturer should offer more than just manufacturing services; they should also provide design and engineering support. This includes helping with design optimization: for example, suggesting changes to the wall thickness of a silicone part to improve its strength without adding excessive material. They can also identify and solve potential design issues: if a design has areas that are difficult to mold or may cause stress concentrations, the manufacturer's engineering team can propose alternative solutions. This collaborative approach between the manufacturer and the client can lead to better - performing prototypes and ultimately, more successful products.

3. Comparing Different Silicone Prototype Manufacturers

When it comes to choosing a silicone prototype manufacturer, comparing different options can be a daunting task. Here, we will compare three well - known manufacturers - Manufacturer A, Manufacturer B, and Manufacturer C - across several key aspects:

| Aspect | Manufacturer A | Manufacturer B | Manufacturer C |

| Price | Medium - high. Their pricing is based on a combination of material costs, complexity of the design, and production volume. For a simple silicone prototype with a volume of 100 units, the cost might be around \(500 - \)800. | Low - medium. They offer competitive pricing, especially for high - volume orders. For the same 100 - unit simple prototype, the cost could range from \(300 - \)600. | High. Known for their premium services and high - end products, a 100 - unit simple prototype may cost \(800 - \)1200. |

| Delivery Time | Usually 1 - 2 weeks for small - scale orders. For larger orders or complex designs, it may extend to 3 - 4 weeks. | Fastest among the three. Can complete small - scale orders within 1 week and larger, more complex orders in 2 - 3 weeks. | Longest delivery time. Small - scale orders take 2 - 3 weeks, and complex, large - scale orders can take up to 5 - 6 weeks. |

| Quality | High - quality products. They use top - grade silicone materials and have a strict quality control system with multiple inspection points during production. Their products have a defect rate of less than 2%. | Good quality. The silicone materials used meet industry standards, and they conduct regular quality checks. However, the defect rate is slightly higher at around 3 - 4%. | Exceptional quality. They source the best - in - class silicone materials and have a state - of - the - art quality control process. Their defect rate is less than 1%. |

| Service | Offers design support, but it is more focused on basic design advice. Responsive customer service, with a 24 - hour turnaround time for inquiries. | Provides comprehensive design and engineering support, helping clients optimize their prototypes. Customer service is available round - the - clock, and they also offer after - sales support for any product - related issues. | Limited design support, mainly focusing on manufacturing. Their customer service is professional but has a 48 - hour response time for inquiries. |

Yigu Technology's View

As a non - standard plastic and metal products custom supplier, Yigu Technology believes that when choosing silicone prototype manufacturers, in addition to focusing on the professionalism and experience mentioned above, the manufacturer's innovation ability and rapid response to customer needs should also be highly valued. A good manufacturer should not only be able to produce high - quality prototypes but also provide customized solutions according to the special requirements of customers. For example, if a client has a unique design concept that requires special silicone materials or complex molding techniques, an innovative manufacturer can explore new methods and materials to meet these needs. This kind of flexibility and innovation can help customers gain a competitive edge in the market. Additionally, quick response times to customer inquiries and the ability to adjust production schedules according to customer needs are also crucial factors for a reliable silicone prototype manufacturer.

FAQs

What is the typical lead time for silicone prototype manufacturing?

The typical lead time for silicone prototype manufacturing usually ranges from 1 - 3 weeks. For small - scale and relatively simple orders, it can often be completed within 1 week. However, for larger orders or those with complex designs, it may take up to 3 weeks or even longer. Factors such as the complexity of the design (intricate geometries and multiple components will take more time), the quantity of the order (higher volumes require more production time), and the availability of materials can all influence the lead - time. For example, if a unique silicone material needs to be sourced, it may add a few days to the overall production schedule.

How can I ensure the quality of silicone prototypes?

To ensure the quality of silicone prototypes, first, choose a manufacturer with relevant quality certifications, such as ISO 9001. This indicates that they follow international quality management standards. Secondly, request sample test reports from the manufacturer. These reports should include results of material property tests like tensile strength and elongation tests, as well as dimensional accuracy checks. Additionally, conduct pre - production meetings with the manufacturer to clearly define your quality requirements and inspection criteria. You can also ask for in - process inspection reports during production to monitor the quality progress.

Can silicone prototype manufacturers help with design modifications?

Most professional silicone prototype manufacturers can provide design modification suggestions and support. They have experienced engineering teams with in - depth knowledge of silicone materials and manufacturing processes. For example, if the initial design has thin - walled sections that may be difficult to mold during injection molding, the manufacturer can suggest thickening those areas or adding rib structures to improve the moldability. In a project for designing a silicone - based smartphone case, the manufacturer noticed that the original design's corners were likely to experience stress concentration during use. They proposed rounding the corners and adding small grooves around the edges, which not only enhanced the case's durability but also improved its aesthetic appeal.