Introduction to 3D Prototype Printing

In today's fast-evolving industries, innovation is a primary driver of competitiveness. One of the most transformative technologies enabling rapid innovation is 3D prototype printing. This technology has revolutionized how products are designed, tested, and produced across diverse industries. Whether you're in aerospace, automotive, medical, consumer goods, or construction, understanding the benefits and applications of 3D prototype printing can significantly enhance your business’s ability to compete in a fast-paced market.

Definition and Technology Overview

What is 3D Prototype Printing?

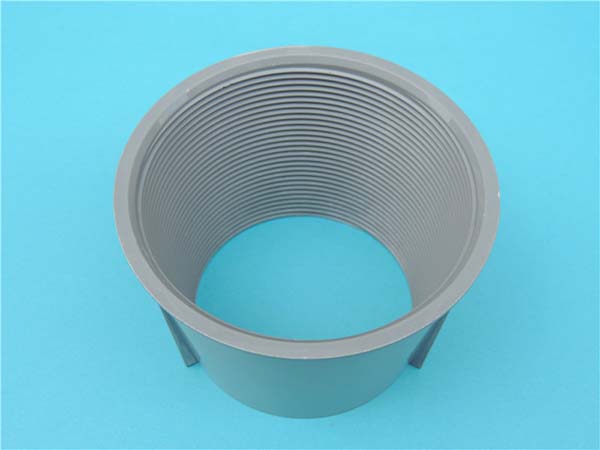

3D prototype printing, also known as additive manufacturing, is a process where three-dimensional objects are created layer by layer from a digital design. Unlike traditional subtractive manufacturing methods, which carve or remove material from a solid block, 3D printing adds material to build the final object, directly from a Computer-Aided Design (CAD) file. This process allows for the creation of highly detailed prototypes that can be tested, refined, and adjusted quickly.

How Does it Work?

The process of 3D prototype printing begins with a 3D model created using CAD software. Once the design is ready, it is sliced into thin horizontal layers by slicing software. These slices are sent to the 3D printer, which prints each layer, one at a time, until the object is complete.

There are several types of 3D printing technologies, including:

- Fused Deposition Modeling (FDM): Uses a filament that is heated and extruded through a nozzle to form layers.

- Stereolithography (SLA): Uses a laser to cure liquid resin layer by layer.

- Selective Laser Sintering (SLS): Uses a laser to fuse powdered material into solid layers.

- Digital Light Processing (DLP): Similar to SLA but uses a digital light projector to cure resin.

Each technology has its own set of advantages and is suitable for specific types of prototypes and applications.

Benefits of 3D Prototype Printing Services

1. Speed and Efficiency

One of the most significant advantages of 3D prototype printing is speed. Traditional prototyping often involves lengthy processes such as tooling, molding, and manual assembly, which can take weeks or even months. In contrast, 3D printing can produce prototypes in hours or days, dramatically accelerating the design and testing phases of product development. This rapid prototyping ability allows businesses to iterate quickly, bringing products to market faster.

2. Cost-Savings

Although the initial investment in 3D printing equipment can be significant, the long-term cost savings are substantial. Traditional prototyping often requires the creation of expensive molds and tools, each of which may need to be replaced or modified multiple times during the development cycle. 3D printing eliminates these costs, allowing companies to produce high-quality prototypes without the expense of tooling. Additionally, there are no material waste concerns since additive manufacturing uses only the material required for each layer.

3. Design Complexity and Flexibility

3D printing provides the ability to create complex geometries and intricate designs that would be impossible or cost-prohibitive to achieve with traditional manufacturing methods. This design flexibility enables engineers and designers to create prototypes with internal structures, complex curves, or integrated features. This capability is especially beneficial when designing parts that need to be lightweight, strong, or optimized for specific functions.

4. Customization

Another major benefit is the ability to create customized prototypes that can be tailored to specific needs. Whether it’s individual consumer preferences, ergonomics, or personalized features, 3D printing allows you to produce one-off or small batch prototypes with unique specifications. This level of customization is often too expensive or impractical to achieve using traditional manufacturing methods.

5. Iteration and Testing

With traditional prototyping methods, making changes to a design often involves creating entirely new molds or tools, which can be expensive and time-consuming. In contrast, 3D prototype printing allows for rapid iteration. Engineers can quickly modify the digital model and produce new iterations for testing. This iterative process helps identify and fix issues early, reducing the likelihood of costly design flaws making it into final production.

Applications Across Industries

3D prototype printing is utilized in a variety of industries, each benefiting from the speed, flexibility, and cost-efficiency that additive manufacturing offers. Here are some of the key applications:

1. Aerospace and Automotive

In the aerospace and automotive industries, 3D printing is used to create lightweight, high-strength parts that improve performance and reduce fuel consumption. Prototyping using 3D printing also allows engineers to test parts for aerodynamics, ergonomics, and material properties. For example, NASA has used 3D printing to manufacture engine parts, while automakers like Ford and BMW use it to create functional car components.

2. Medical and Dental

In the medical and dental sectors, 3D printing enables the creation of customized prosthetics, implants, and surgical guides. This technology allows for personalized patient-specific solutions that improve both outcomes and comfort. In dentistry, 3D printing is used for precise dental implants, braces, and even dentures. In the medical field, 3D printed scaffolds for tissue engineering are also being developed to support organ regeneration.

3. Architecture and Construction

In architecture, 3D printing is used to create detailed scale models of buildings and urban designs. This allows architects to visualize projects in physical form and detect potential design flaws before full-scale construction begins. In construction, 3D printing is being used to create customized building components and even entire homes. Companies like ICON and Apis Cor have experimented with printing 3D homes using concrete, which could offer affordable housing solutions at scale.

4. Consumer Goods and Electronics

In the consumer goods and electronics industries, 3D printing is used for creating prototypes of gadgets, appliances, and wearables. This enables companies to quickly test form, fit, and functionality before committing to expensive production runs. Additionally, 3D printing allows for customization in product design, such as personalized phone cases or tailored electronics parts. Companies like Nike and Adidas have used 3D printing to create custom sports equipment and shoe prototypes.

Case Studies and Success Stories

1. Aerospace: NASA and SpaceX

NASA has utilized 3D printing for years, from manufacturing tools to creating parts for spacecraft. SpaceX, too, uses 3D printing to manufacture components for their Rocket Lab engines, reducing production costs and time. These high-stakes applications demonstrate how 3D printing is trusted for its reliability, precision, and efficiency in critical sectors.

2. Medical: Custom Prosthetics

Companies like O&O Prototype Engineering have successfully used 3D printing to create custom prosthetics for patients. These prosthetics are not only more affordable but also better fitting and more comfortable than traditional options, drastically improving the quality of life for patients. This technology has revolutionized the prosthetics market by offering more personalized solutions at a fraction of the cost.

3. Architecture: 3D Printed Homes

In the construction sector, ICON, a 3D printing company, has made headlines for 3D printing affordable homes in Latin America. By using advanced printing techniques, ICON is helping to address global housing shortages while also reducing construction costs. Their mission is to bring affordable, sustainable homes to communities in need.

Choosing the Right 3D Printing Service Provider

Factors to Consider

When selecting a 3D printing service provider for prototyping, consider the following factors:

- Material Options: Ensure the provider offers the materials that fit your project requirements, whether that’s plastic, metal, resin, or flexible materials.

- Print Quality: Look for service providers with a reputation for producing high-quality prints with fine detail and accurate dimensions.

- Turnaround Time: If speed is crucial, choose a provider known for fast delivery times, especially for prototypes that require rapid iteration.

- Cost: Compare pricing among different providers. While it’s important to consider price, ensure that quality is not compromised for cost savings.

- Customer Support: Good communication and support can make a significant difference in ensuring that the prototyping process goes smoothly.

Service Comparison

| Provider | Material Options | Print Quality | Turnaround Time | Cost | Customer Support |

|---|---|---|---|---|---|

| Provider A | Extensive | High | Fast | Moderate | Excellent |

| Provider B | Limited | Medium | Slow | Low | Good |

| Provider C | Moderate | High | Fast | High | Fair |

FAQs

1. What is the typical turnaround time for a 3D printed prototype?

Turnaround time varies depending on the complexity of the design. Simple prototypes may be ready in 1-3days, while more complex parts may take a week or longer.

2. Are there limitations to what can be 3D printed?

While highly versatile, 3D printing has limitations, such as build volume, material constraints, and resolution. Larger prints might require breaking down the design into smaller sections. Not all materials are compatible with every printing method.

3. How much does it cost to get a 3D printed prototype?

Costs vary based on design complexity, material choice, and quantity. Simple prototypes can cost from $50 to $500, while highly complex or custom designs can range into the thousands.

By understanding the key benefits and applications of 3D prototype printing services, businesses can accelerate product development, reduce costs, and explore innovative design possibilities. Whether you’re improving existing products or bringing entirely new ideas to life, 3D prototype printing offers a unique edge in today’s competitive market.