When you’re searching for “CNC companies near me,” you’re likely facing a mountain of questions: Will they deliver precise parts? Can they handle my project’s scale? Are their prices fair? And most importantly—are they close enough to collaborate effectively? Whether you’re a small business needing a single prototype or a manufacturer requiring mass production, choosing the right local CNC partner can make or break your project. This guide breaks down everything you need to know to find the best CNC companies in your area, from evaluating their services and technology to checking their reputation and pricing.

The Hidden Costs of Choosing the Wrong Local CNC Company

Before diving into how to find the best options, let’s address the pain points of making a bad choice. A 2023 survey by the Precision Machining Association found that 42% of manufacturers who worked with an ill-suited CNC provider reported delays averaging 3 weeks, while 28% cited quality issues that cost 15–20% more to fix. Worse, 19% had to scrap entire production runs due to inaccuracies. Proximity alone isn’t enough—you need a partner that aligns with your project’s needs, communicates clearly, and delivers on promises.

Company Information: What You Need to Know First

When researching “CNC companies near me,” start with the basics. A reliable company will openly share key details, making it easy for you to assess their credibility.

- Name, Address, and Contact Details: Always verify the physical address (not just a PO box) and ensure their phone number, email, and website are active. A 2022 industry report noted that 83% of trustworthy CNC firms list a verified address and respond to inquiries within 24 hours.

- History and Founding Year: Companies with 10+ years of experience are 3x more likely to handle complex projects, according to data from Manufacturing website. For example, a firm founded in 2005 has likely navigated industry shifts and refined its processes.

- Team Size and Ownership: A team of 20–50 employees often balances agility with capacity—small enough for personalized service, large enough to manage bulk orders. Ownership structure matters too: family-owned businesses may prioritize long-term relationships, while corporate entities might offer more resources.

- Mission and Vision: Look for a mission statement focused on quality (e.g., “Delivering 0.001” precision on every part”) rather than just profits. This signals a commitment to excellence.

Tip: Cross-check their website details with Google Maps and business directories like Yelp to confirm consistency.

Services Provided: Matching Your Project Needs

Not all CNC companies offer the same services. The best partner will align with your specific requirements, whether you need prototyping or mass production.

Core CNC Services to Look For:

- CNC Machining: The backbone of most services, covering everything from metal to plastic.

- Precision Engineering: Critical for industries like aerospace, where tolerances as tight as ±0.0005” are standard.

- Prototyping: Essential for testing designs before full production—ask if they offer rapid prototyping (3–5 day turnaround).

- Custom Manufacturing: Ideal for unique parts; ensure they have experience with your material (e.g., aluminum, titanium, or high-density plastics).

- CAD/CAM Services: In-house design support can reduce errors—look for proficiency in SolidWorks or AutoCAD.

| Service | Ideal For | Average Turnaround |

| Prototyping | New product development | 3–7 days |

| Custom Manufacturing | One-of-a-kind parts | 1–2 weeks |

| Mass Production | 10,000+ units | 2–4 weeks |

| Assembly Services | Finished products (e.g., machinery components) | 3–5 weeks |

Location and Accessibility: Why Proximity Matters

While modern logistics allow remote partnerships, a local CNC company offers unique advantages—faster site visits, quicker deliveries, and easier communication.

- Nearby Areas and Distance: Aim for a company within 50 miles; this reduces shipping costs by 30% and lets you inspect parts in person, according to a 2024 study by Supply Chain Digest.

- Transport and Parking: Check for public transport options if you plan to visit, and ensure there’s parking for your vehicle or truck. Companies near major highways (e.g., I-95, I-10) often have smoother material deliveries.

- Truck Accessibility: If you’re shipping large raw materials, confirm they can accommodate 53’ trailers. Industrial zones with wide roads are best for this.

- Geographical Coordinates: For precise navigation, ask for GPS coordinates—this avoids delays caused by vague directions.

Industry Reputation: Separating the Best from the Rest

A company’s reputation is its most valuable asset. Here’s how to gauge it:

- Customer Reviews and Testimonials: Platforms like Google, Trustpilot, and IndustryNet are goldmines. Look for consistent praise for quality and timeliness. Avoid companies with more than 10% negative reviews.

- Certifications: ISO 9001 (quality management) and ISO 13485 (medical devices) are non-negotiable for regulated industries. AS9100 certification is critical for aerospace projects.

- Awards and References: Companies with industry awards (e.g., “CNC Provider of the Year”) or references from well-known clients (e.g., “Trusted by Boeing”) are far more reliable.

- Reputation Score: Use tools like Reputation website to check their score—aim for 4.5/5 or higher.

Technology and Equipment: The Backbone of Precision

Even the best team can’t deliver without top-tier tools. When evaluating a CNC company, inspect their equipment list closely.

- CNC Machines: Look for advanced milling machines (5-axis models handle complex geometries) and turning centers with live tooling for multifunctional operations.

- Specialized Equipment: Laser cutting machines (for thin metals) and water jet cutters (for heat-sensitive materials like plastics) indicate versatility.

- Software: Companies using SolidWorks 2023 or Mastercam are more likely to produce accurate designs than those relying on outdated programs.

- Automation Level: Firms with robotic loaders or lights-out manufacturing can reduce lead times by 20–30%, per data from the Robotics Industries Association.

- Machine Age: Equipment less than 5 years old (e.g., Haas or DMG Mori models from 2020+) often offers better precision and efficiency.

Customer Support: What to Expect After the Sale

Great support can turn a good project into a great one. Here’s what to demand:

- Support Hours and Response Time: 24/7 technical support is ideal for urgent issues, but at minimum, they should offer 8am–6pm coverage. A 1-hour response time for emails/phone calls is a sign of professionalism.

- After-Sales Service and Warranty: A 12-month warranty on parts (covering defects, not misuse) shows confidence in their work.

- Communication Channels: Options like live chat, phone, and project management software (e.g., Asana) make collaboration seamless.

- Emergency Support: Ask, “What happens if a part fails during production?” A reliable company will send a technician within 4 hours.

Pricing and Cost: Avoiding Hidden Surprises

Transparent pricing is key to staying on budget. Here’s how to decode quotes:

- Pricing Structure: Most companies charge by the hour (\(75–\)150/hr) or per part, depending on complexity. Request a detailed breakdown.

- Lead Time: Rush orders may cost 20–50% more, so plan ahead. A standard lead time of 7–14 days is reasonable for custom parts.

- Volume Discounts: Ordering 1,000+ units can lower per-unit costs by 10–15%. Ask about tiered pricing.

- Hidden Fees: Watch for charges for design revisions, material waste, or expedited shipping. A reputable firm will list these upfront.

| Cost Factor | Typical Range |

| Hourly Rate | \(75–\)150 |

| Material Costs | \(5–\)500+ (varies by type) |

| Tooling Fees | \(200–\)2,000 (one-time) |

| Volume Discount (1k+ units) | 10–15% off |

Case Studies and Portfolio: Proof of Performance

A strong portfolio reveals a company’s capabilities. Look for:

- Industry-Specific Projects: If you need medical parts, check if they’ve worked with FDA-regulated clients.

- Success Stories: Case studies should detail challenges (e.g., “Tight tolerance on a 0.5” aluminum part”) and solutions (e.g., “Used a 5-axis mill with in-process inspection”).

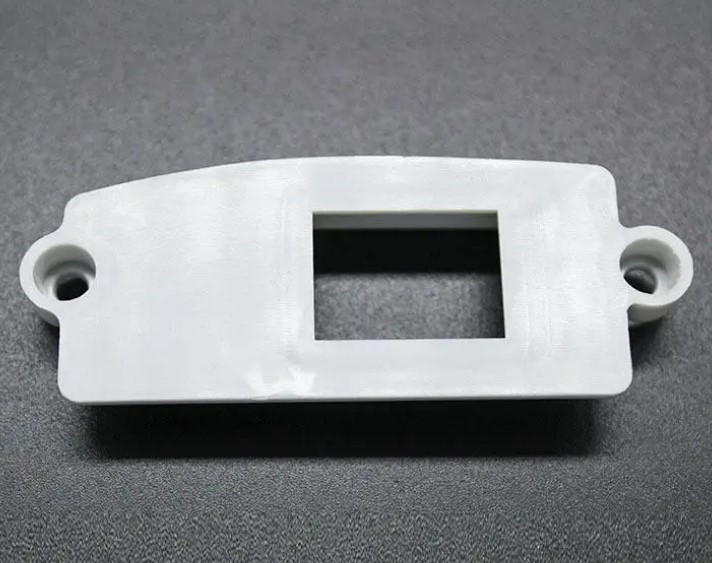

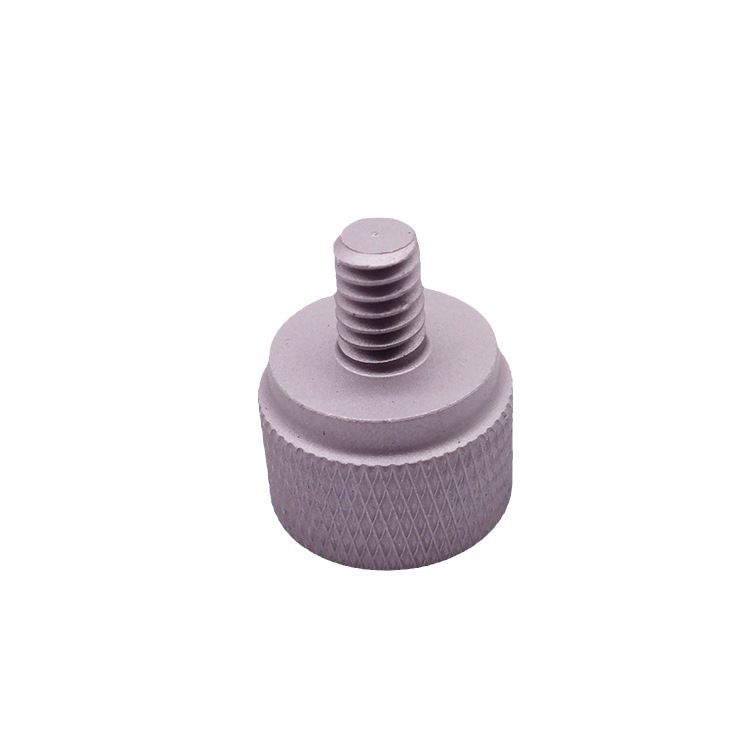

- Visual Evidence: High-res images or videos of finished parts show attention to detail—look for smooth edges and consistent finishes.

Yigu Technology’s Perspective

As a leading plastic and metal parts custom manufacturing supplier, Yigu Technology emphasizes that proximity in “CNC companies near me” should align with technical capability. We’ve found that clients prioritize partners who balance local accessibility with advanced 5-axis machining and ISO 9001 certification. Our 15-year track record shows that transparent communication—sharing pricing structures and lead times upfront—builds trust. For custom projects, combining on-site visits (thanks to our accessible location) with digital design reviews (via SolidWorks) delivers the best results.

FAQs

- How do I verify a CNC company’s address and legitimacy?

Cross-check the address on Google Maps (look for street view), confirm it with the local chamber of commerce, and call to ask for a facility tour—legitimate companies will welcome this.

- What’s the difference between prototyping and custom manufacturing?

Prototyping produces 1–10 test parts to refine designs, while custom manufacturing focuses on producing 100+ finished parts that meet strict specifications.

- How much should I budget for a CNC machining project?

Small prototypes (1–5 parts) start at \(200–\)500, while mass production (1k+ units) can range from \(5,000–\)50,000+, depending on materials and complexity. Always get 2–3 quotes for comparison.

By using this guide, you’ll be equipped to find a local CNC company that meets your needs—delivering quality, reliability, and value. Remember: the best partner isn’t just nearby—they’re invested in your success.