Introduction

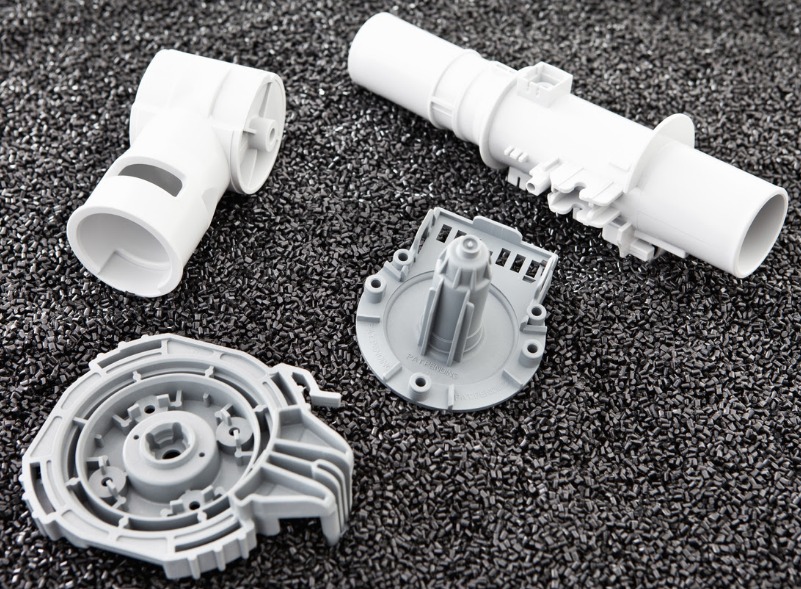

High-Impact Polystyrene (HIPS) is a go-to material for parts needing both affordability and toughness, but molding it comes with unique challenges. Manufacturers often struggle with balancing impact strength and process efficiency, dealing with defects like weld lines or warpage, and optimizing molds for HIPS’ rubber-modified structure. Whether you’re producing toys, appliance housings, or automotive components, getting HIPS injection molding right requires precise control over process parameters, material selection, and mold design. This guide dives into these critical areas to help you overcome hurdles and produce high-quality HIPS parts consistently.

HIPS Injection Molding Process Parameters

Key Settings for Optimal Results

- HIPS melt temperature range: HIPS melts at 200–240°C, higher than general-purpose polystyrene (GPPS) due to its rubber content. Going below 190°C can cause poor flow and short shots, while exceeding 260°C risks degrading the rubber phase, reducing impact strength.

- Injection speed vs impact strength: A moderate injection speed (40–80 mm/s) works best. Slow speeds (below 30 mm/s) can create weak weld lines, while very high speeds (over 100 mm/s) may shear the rubber particles, lowering impact resistance. Matching speed to part complexity—faster for thin walls, slower for thick sections—balances flow and strength.

- Holding pressure HIPS optimization: Set holding pressure to 60–70% of injection pressure (typically 600–1000 bar) and hold for 2–5 seconds. This prevents sink marks in thick areas without overpacking, which can cause stress or warpage.

- Screw L/D ratio for HIPS: A screw with an L/D ratio of 20:1 to 24:1 ensures proper melting and mixing of the rubber and polystyrene phases. Avoid L/D ratios below 18:1, as they may leave unmelted particles, weakening the part.

Efficiency Boosters

- Hot-runner temperature profile: For hot-runner systems, keep nozzle temperatures 5–10°C higher than the melt temperature (210–250°C) to prevent premature cooling. Zone temperatures should gradient from the sprue to the gate, ensuring uniform flow.

- Cooling time reduction HIPS: HIPS cools slower than GPPS due to its rubber content. Typical cooling times are 15–40 seconds, but you can cut this by 10–15% using conformal cooling channels or increasing mold coolant flow rate—just avoid rapid cooling, which can trap stress.

HIPS Material Characteristics & Impact Modifiers

Core Properties

- Rubber content in HIPS: Usually 5–15% (by weight) of polybutadiene rubber, which forms particles dispersed in the polystyrene matrix. Higher rubber content boosts Izod impact strength HIPS (from 2 to 5 kJ/m²) but reduces rigidity and increases cost.

- MFI of high-impact polystyrene: Melt Flow Index (MFI, measured at 200°C/5kg) ranges from 1 to 20 g/10min. Higher MFI (10–20) improves flow for complex parts but slightly lowers impact strength, while lower MFI (1–5) offers better toughness for structural components.

- Transparency vs toughness trade-off: Unlike GPPS, HIPS is opaque due to light scattering by rubber particles. This is a deliberate trade-off—sacrificing transparency for up to 5x higher impact resistance than GPPS.

Functional Additives

- UV-stabilized HIPS grades: Add carbon black or UV absorbers to protect against sunlight-induced degradation, extending lifespan in outdoor applications like garden tools or outdoor furniture.

- Flame-retardant HIPS additives: Phosphorus-based or brominated additives meet fire safety standards (e.g., UL 94 V-0) for electrical enclosures and consumer electronics, though they may slightly reduce impact strength.

Mold & Part Design Guidelines for HIPS

Critical Design Features

- Gate size for HIPS impact resistance: Use larger gates (1.0–2.0 mm diameter) than for GPPS to reduce shear on rubber particles. Edge gates or tab gates work well—avoid pinpoint gates, which can shear rubber and weaken the part. For high-impact areas, locate gates to minimize weld lines.

- Draft angle HIPS thick-wall parts: Thick sections (>3 mm) need draft angles of 1.5–2° to prevent ejection issues, as HIPS is more flexible than GPPS and can stick to molds. For thin walls (<2 mm), 1° draft suffices.

- Rib-to-wall thickness ratio HIPS: Keep ribs at 50–70% of the parent wall thickness to avoid sink marks. For example, a 3 mm wall should have ribs 1.5–2.1 mm thick. This ratio prevents uneven cooling and maintains impact strength.

Mold Optimization

- Venting depth to prevent burns: HIPS requires deeper vents (0.03–0.06 mm) than GPPS to release trapped air, especially in complex molds. Inadequate venting causes burn marks, which weaken the part and ruin aesthetics.

- Mold temperature control for gloss: Maintain mold temperature at 40–60°C. Higher temperatures (50–60°C) improve surface gloss, ideal for visible parts like appliance panels, while lower temperatures (40–45°C) speed cooling for faster cycle times.

- Shrinkage compensation HIPS: HIPS shrinks 0.5–0.8%, slightly more than GPPS. Compensate by enlarging mold cavities by 0.6% to ensure final parts meet dimensional tolerances (typically ±0.2 mm for medium-sized parts).

Defect Analysis & Troubleshooting in HIPS Molding

Common Issues and Solutions

- Silver streaks HIPS moisture: Moisture absorbed by HIPS (even small amounts) vaporizes during molding, causing silver streaks. Dry HIPS at 70–80°C for 2–4 hours before processing to reduce moisture below 0.05%.

- Weld line strength drop HIPS: Weld lines form where two melt fronts meet, reducing impact strength by 30–50%. To improve them: increase melt temperature by 10–15°C, raise injection speed, or add a weld line enhancer additive. Locating gates to minimize weld lines in high-stress areas also helps.

- Warpage due to rubber phase orientation: Uneven cooling or excessive shear can orient rubber particles, causing warpage. Fixes include: using uniform wall thickness, optimizing cooling channel layout, and reducing holding pressure by 5–10% to minimize stress.

- Short shot at low injection speed: HIPS’ higher viscosity (compared to GPPS) requires sufficient injection speed to fill molds. If short shots occur, increase speed by 10–20% or raise melt temperature by 5–10°C—avoiding excessive shear.

- Sink marks behind ribs HIPS: These are caused by uneven cooling. Increase cooling time by 10–15% for thick ribs, or adjust holding pressure to pack more material into the area without overstressing the part.

- Color streaks from masterbatch: HIPS’ rubber phase can trap undispersed color masterbatch, causing streaks. Use a masterbatch designed for HIPS, increase screw speed by 10–15% to improve mixing, or pre-blend the masterbatch with HIPS pellets.

Yigu Technology's View

As a parts custom manufacturing supplier, Yigu Technology specializes in HIPS injection molding. We optimize HIPS melt temperature and injection speed to balance impact strength and efficiency, ensuring parts like toy components or appliance housings meet toughness requirements. Our expertise in rib design and venting minimizes defects, while our troubleshooting skills resolve issues like weld lines or warpage quickly. Trust us to deliver consistent, high-quality HIPS parts tailored to your needs—on time and within budget.

FAQs

- How does HIPS compare to ABS in impact strength?

HIPS has good impact strength (2–5 kJ/m²) but is outperformed by ABS (10–20 kJ/m²). However, HIPS is 20–30% cheaper, making it ideal for non-critical applications like toys or packaging.

- Can HIPS be recycled?

Yes, HIPS is recyclable (resin code 6) and retains most of its impact strength after recycling, though it may need blending with virgin HIPS for high-performance parts.

- What causes HIPS parts to become brittle over time?

Exposure to UV light (without stabilizers) or high temperatures (>80°C) degrades the rubber phase, reducing toughness. Using UV-stabilized HIPS and avoiding prolonged heat exposure prevents this.