The discussion about resin 3D printing is changing. It has grown from a hobby tool for simple visual models into an advanced technology for professional prototyping and small-scale manufacturing. For engineers and product designers, the goal is no longer just to print an object, but to create a working part that meets strict performance standards. This guide goes beyond basic principles to provide detailed methods for professionals. We will explore the science behind choosing materials, advanced print process improvement for tiny features, and the important role of research-based post-curing methods to achieve the best mechanical properties. This article provides practical techniques for using high-quality resin printing for high-performance parts.

The key areas we will cover include:

- A detailed look into engineering material science.

- Advanced print process and software improvement.

- Research-based post-curing methods for performance.

- Real-world application examples.

The Foundation for Demanding Applications

Choosing the right manufacturing technology is the first important decision in any engineering project. While methods like Fused Deposition Modeling (FDM) and Selective Laser Sintering (SLS) have their strengths, high-quality resin printing (SLA/DLP/LCD) holds a unique and important position. It excels in applications where fine detail, smooth surface finish, and consistent material properties are not just wanted, but essential for function. The following comparison shows its specific advantages for professional use cases, proving the investment in this technology for creating high-quality prototypes and final parts.

A Comparative Overview

The basic difference lies in how parts are formed. Resin printing hardens liquid materials layer by layer, resulting in a fully solid, smooth object. This contrasts with the extruded lines of FDM and the heated powder of SLS. For applications demanding precision, resin printing is often the better choice.

| Feature | Resin Printing (SLA/DLP) | Fused Deposition Modeling (FDM) | Selective Laser Sintering (SLS) |

| Typical Resolution | 25-100 microns | 100-400 microns | ~100 microns |

| Surface Finish | Very Smooth, Injection-mold like | Visible Layer Lines | Granular, Matte |

| Part Isotropy | High (nearly isotropic) | Low (anisotropic, weaker Z-axis) | High |

| Best For | Fine details, smooth surfaces, prototypes, casting patterns | Quick, low-cost prototypes, large parts | Complex shapes, functional nylon parts |

Material Science Deep Dive

Selecting the right material is extremely important for a successful project. The large library of available resins allows for a level of application-specific use that is unmatched by many other 3D printing technologies. Moving beyond basic "standard" resins unlocks the ability to create parts with specific mechanical, thermal, or biological properties. This section provides an expert-level guide to navigating these advanced materials based on engineering requirements and data-driven decisions.

Tough vs. Castable Resins

Engineers often face a choice between creating a functional, durable part or a pattern for metal casting. This requires two completely different classes of materials: Tough and Castable resins. Understanding their property trade-offs is important.

Tough resins are designed for mechanical performance. Their main purpose is to create parts that can withstand stress, impact, and bending. They focus on high impact strength, tensile strength, and elongation at break. This chemical composition allows them to absorb energy and bend before breaking, making them ideal for snap-fit cases, jigs, fixtures, and functional prototypes that will undergo physical testing. This durability often comes at the cost of slightly lower stiffness (flexural modulus) and can sometimes affect the finest print resolution compared to more brittle resins.

Castable resins serve a single, highly specialized purpose: clean burnout for investment casting. Their formulation focuses on an extremely low ash content (often below 0.1%) after the burnout cycle in a kiln. To achieve this, their polymer structure is designed to completely vaporize at high temperatures, leaving behind a clean cavity in the investment mold. This important property comes at a significant compromise to all mechanical properties. Castable resin parts are typically very brittle and are completely unsuitable for any form of functional testing.

| Mechanical Property | Engineering Tough Resin | Castable Wax Resin | Implication |

| Tensile Strength | 45-60 MPa | 5-15 MPa | Tough resins withstand significant pulling forces. |

| Elongation at Break | 30-100% | 2-5% | Tough resins can bend and change shape before breaking. |

| Impact Strength (Izod) | 35-100 J/m | <10 J/m | Tough resins resist sudden shocks and drops. |

| Clean Burnout | Poor | Excellent (<0.1% Ash) | Castable resins are designed to vaporize completely. |

Biocompatible Resins (ISO 10993)

For medical device applications, material safety is non-negotiable. Biocompatible resins are a specialized class of materials that have been tested and certified according to ISO 10993. This is a series of international standards for evaluating the biocompatibility of medical devices to manage biological risk. These materials are safe for varying levels of contact with the human body.

Certifications are often specified by class, such as Class I for devices in contact with intact skin (e.g., surgical guides) and Class IIa for short-term mucosal or internal contact (e.g., certain dental devices). The use of these specialized resin printing models is growing rapidly in the medical field for applications including:

- Patient-specific surgical guides

- Dental splints, temporary crowns, and try-ins

- Hearing aid shells and earmolds

- Customized prosthetics and orthotics

It is important to understand that biocompatibility is not a property of the resin alone; it is a result of a validated workflow. To maintain the certification, the user must use the specific printer, resin, and prescribed post-processing steps (washing and curing parameters) outlined by the manufacturer. Any deviation from this validated process, such as using a different curing unit or changing cure times, invalidates the biocompatibility certification of the final part.

A Broader Look at Engineering Resins

Beyond Tough and Biocompatible materials, the engineering resin portfolio includes several other key functional types that solve specific industrial challenges.

High-Temperature Resins are designed for applications requiring thermal stability under load. Their defining property is a high Heat Deflection Temperature (HDT), which indicates the temperature at which a material will begin to bend under a specific load. This makes them suitable for creating injection mold inserts for short runs, components for hot fluid flow analysis, and fixtures used in thermal manufacturing processes.

Flexible and Elastic Resins copy the properties of rubber. They are characterized by their Shore Hardness (e.g., 50A, 80A), which defines their softness and flexibility. These materials are ideal for prototyping seals, gaskets, soft-touch grips, wearables, and any part that needs to compress or bend.

ESD-Safe Resins are engineered to safely dissipate static electricity. These materials contain conductive additives that prevent the buildup of a static charge, which could otherwise damage sensitive electronic components. They are essential for producing custom jigs, fixtures, and cases used in the assembly and handling of printed circuit boards (PCBs) and other electronics.

Mastering the Print Process

Achieving truly high-quality results for demanding applications goes far beyond default software settings. It requires a deep understanding of the relationship between part shape, material properties, and machine parameters. This section reveals expert-level techniques for improving the printing process, focusing on challenges that professionals frequently encounter, such as preserving micro-features and maximizing print speed without sacrificing quality. This is where a skilled operator can transform a good print into a perfect one.

Support Optimization for Micro-Features

One of the most significant challenges in resin printing is supporting parts without damaging or hiding fine details. Features smaller than 0.2 mm, such as small pins, raised text, sharp edges, or textured surfaces, can be easily damaged by standard support structures. Advanced support strategies are necessary to preserve these important features.

We employ a multi-faceted approach based on extensive experience:

1. Strategic Orientation: First, angle the part on the build plate to ensure the most important and delicate features are not facing the plate and do not require direct support contact. Protect A-class surfaces.

2. Utilize "Light" Support Presets: Begin with the software's lightest support preset as a baseline. These presets use smaller touchpoints and less dense structures, which are easier to customize.

3. Reduce Touchpoint Size: Manually edit the supports that connect to or are near micro-features. Reduce the support tip diameter to as small as 0.1-0.15 mm. This dramatically minimizes surface scarring upon removal.

4. Increase Support Density: To compensate for the weaker connection of smaller touchpoints, increase the number of supports around the feature. This distributes the peeling forces and ensures the feature remains stable during the printing process.

5. Leverage "Tree" or "Organic" Supports: Most modern software offers advanced support types that branch out from a single trunk. Use these structures to reach difficult, overhanging areas while minimizing contact points on the model's visible surfaces.

6. Consider Post-Cure Removal: The timing of support removal is material-dependent. For some tough resins, supports are easier to remove cleanly after the part is fully cured, as the part is more durable. For more brittle resins, removing supports in the "green" (pre-cured) state is often better to prevent part fracture. Experimentation with a test piece is key to determining the optimal workflow for a specific resin.

The Physics of Print Speed

Print speed in DLP/LCD resin printing is not just about layer height and exposure time; it is basically limited by the fluid dynamics of the resin. A key property governing this is viscosity, a measure of a fluid's resistance to flow, typically measured in centipoise (cP).

The relationship between viscosity and speed is a direct mechanical one:

- High Viscosity Resins (>1000 cP): These thick, honey-like resins flow slowly. After the build plate lifts to peel a layer, a longer "light-off delay" or "wait time" is required for the resin to flow back into the gap and settle. Furthermore, the peeling forces generated when separating the cured layer from the FEP/PFA film are higher, often requiring slower lift speeds to prevent layer separation or part failure.

- Low Viscosity Resins (<500 cP): These thin, water-like resins flow quickly. This allows for significantly shorter wait times between layers. The lower viscosity also reduces peel forces, enabling faster lift speeds. The cumulative effect of these small time savings per layer can reduce total print time by 30-50% or more on tall parts.

To leverage this, we recommend two actionable strategies:

- For speed-critical applications like rapid iteration, select a resin with a low viscosity if its mechanical properties meet the project requirements. Check the material's Technical Data Sheet (TDS) for this value.

- Gently heating the resin can dramatically lower its viscosity. Using a dedicated resin vat heater or maintaining a controlled ambient temperature in the print environment (ideally 25-30°C) can significantly accelerate print times, even with higher-viscosity engineering materials.

Fine-Tuning Software Settings

Producing high-quality resin printing models requires a detailed understanding of how important software settings interact.

Layer Height directly dictates the trade-off between vertical resolution and speed. A 25-micron layer height will produce a smoother surface with less visible stepping but will take twice as long as a 50-micron print.

Exposure Time is a delicate balance. Under-curing results in weak, bendable parts, loss of fine detail, and potential print failures. Over-curing, or light bleed, causes photons to cure resin beyond the intended layer geometry, leading to a loss of dimensional accuracy, closed holes, and swollen features. Calibration prints are essential for dialing in the perfect exposure for each specific resin and layer height.

Lift Speeds and Light-Off Delay are directly linked to resin viscosity and peel forces. A high-viscosity resin requires a slow lift speed and a long delay. A low-viscosity resin can tolerate a fast lift speed and a short delay. Tuning these parameters together is important for preventing layer separation and achieving maximum print speed without compromising reliability.

Advanced Post-Curing for Performance

The post-processing stage, particularly post-curing, is often misunderstood as a simple hardening step. For professional applications, it is a important engineering process that dictates the final mechanical and thermal properties of the part. A "green" part straight from the printer has only partially formed polymer chains and has not reached its full potential. Proper post-curing completes this polymerization, transforming a fragile print into a high-performance functional component.

Post-Curing Protocols

Post-curing works by exposing the part to additional UV light and, often, heat. This energy drives the completion of the polymer cross-linking process that was initiated during printing, locking the polymer chains into a rigid, stable network. Achieving the properties listed on a material's technical data sheet is dependent on following a precise post-curing protocol.

The important variables are wavelength, time, and temperature.

Most professional resins are designed to react optimally to a specific wavelength of UV light, typically 405nm. Using a curing station with the wrong wavelength (e.g., a generic 365nm nail lamp) will be highly inefficient and may result in an under-cured part that never reaches its peak properties, regardless of the curing time. Always check the manufacturer's TDS for the recommended wavelength.

Time and temperature are interdependent factors that determine the degree of cure. For many advanced engineering resins, curing at an elevated temperature (e.g., 60°C or higher) is not just recommended; it is required. Heat accelerates the cross-linking reaction, allowing the material to achieve its maximum tensile strength, flexural modulus, and Heat Deflection Temperature (HDT) more effectively and often more quickly than curing at room temperature.

| Curing Condition | Relative Time to Peak Strength | Achievable Peak Tensile Strength |

| Curing at 25°C | Slower | Lower |

| Curing at 60°C | Faster | Higher (as specified on TDS) |

A Professional Workflow

To achieve consistent, optimal results and parts that meet specification, a structured post-processing workflow is essential.

1. Part Washing: Use a two-stage washing process to ensure all uncured resin is removed. The first bath, using IPA or a suitable solvent, serves as the "dirty" wash to remove the bulk of the resin. The second, "clean" bath of fresh solvent removes any remaining film.

2. Drying: After washing, the part must be thoroughly dried. Use compressed air to blow solvent out of any crevices, blind holes, or channels. Trapped solvent will inhibit the post-cure process in those areas, leaving them weak and tacky.

3. Support Removal: The decision of when to remove supports—before or after curing—should be made based on the material's properties and the desired surface finish, as discussed in the support optimization section.

4. Final Curing: Place the clean, dry part in a dedicated curing station that provides precise control over time, temperature, and wavelength. Follow the protocol specified in the resin's TDS exactly. This is the only way to guarantee the final part will perform as designed.

5. Optional Finishing: Once fully cured, the part is stable. For applications requiring an A-class surface, parts can be wet-sanded with fine-grit sandpaper, polished with a compound, or painted to achieve the desired look.

High-Quality Resin Printing in Action

The true value of these advanced techniques is demonstrated through their application in solving real-world engineering challenges. These brief case studies ground the technical information in practical scenarios, proving the value of a science-based approach to resin 3D printing.

Case Study 1: Electronics Case

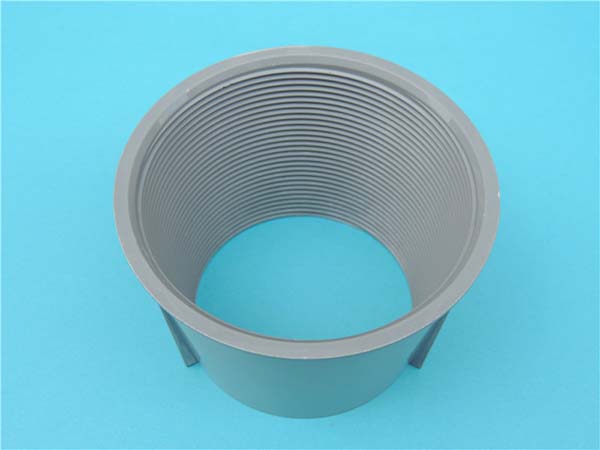

- Goal: Create a dimensionally accurate, snap-fit case prototype for a new consumer electronic device. The prototype needed to be durable enough for functional testing and have a smooth surface finish for marketing photography. Important features included snap-fit tabs smaller than 1mm.

- Resin & Technique: An engineering Tough Resin was selected for its impact resistance and elongation, ensuring the snap-fits could function without breaking. The part was oriented at a 45-degree angle to minimize layer lines on cosmetic surfaces. Advanced support strategies were used, with manually edited micro-supports (0.15mm touchpoints) placed carefully around the snap-fit features to prevent scarring.

- Outcome: A fully functional prototype was printed, processed, and assembled in under 24 hours. This allowed the design team to rapidly validate the fit and function before committing to expensive injection mold tooling. The supports were removed cleanly post-cure, leaving minimal surface markings that were easily polished away.

Case Study 2: Biocompatible Surgical Guide

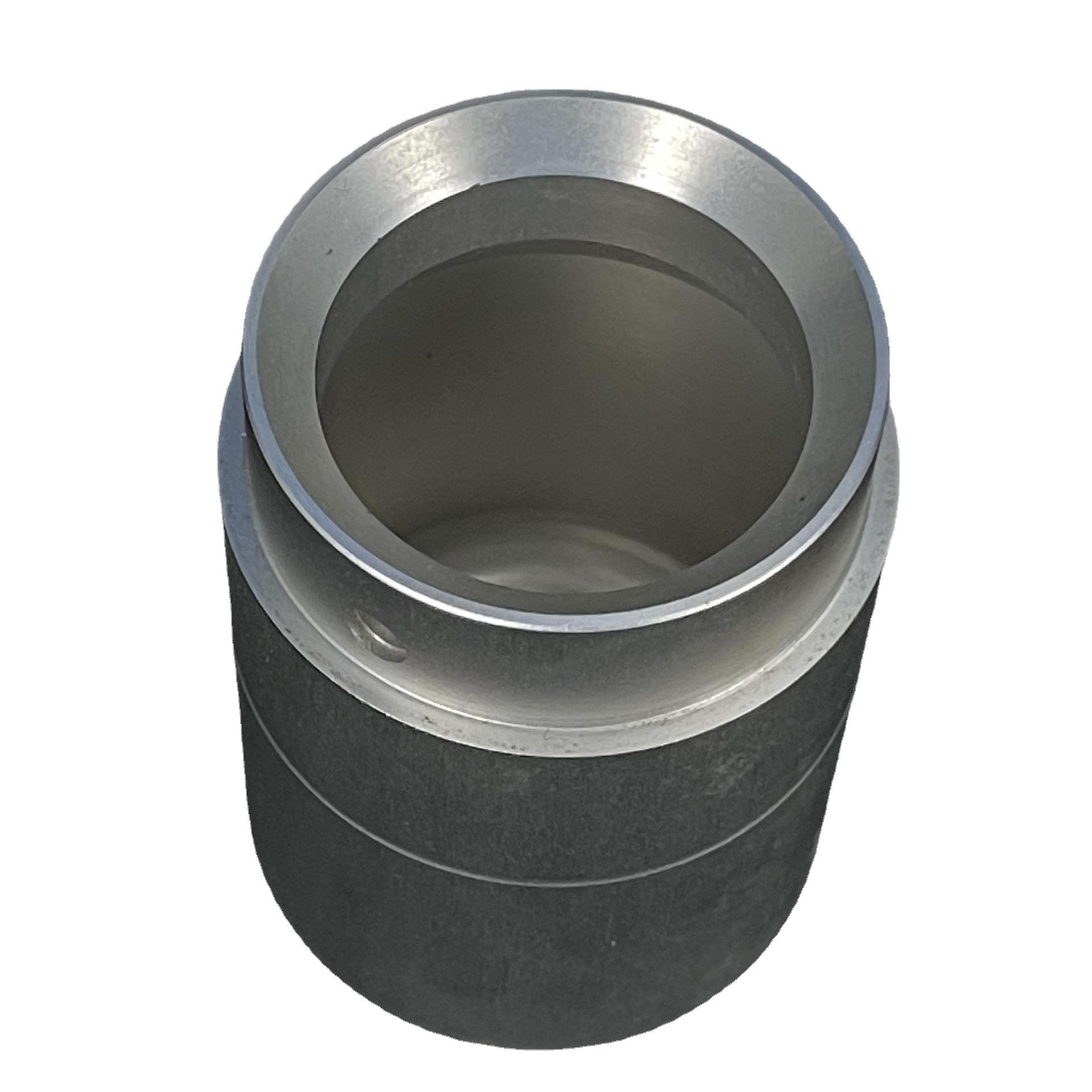

- Goal: Manufacture a patient-specific drill guide for a dental implant surgery. The part required extreme accuracy to match the patient's anatomy and had to be sterile and safe for short-term contact within the oral cavity.

- Resin & Technique: An ISO 10993 certified Biocompatible Resin was used. A fully validated and documented workflow was followed without deviation. This included using the manufacturer-specified software profiles for the printer, a two-stage IPA wash, and a precise post-curing cycle in a validated curing unit (e.g., 20 minutes at 60°C with 405nm light).

- Outcome: A sterile, safe, and highly accurate surgical guide was produced. The guide fit the patient's anatomy perfectly, enabling the surgeon to perform the implant procedure with greater precision and confidence, ultimately improving the patient outcome. This case demonstrates a true end-use part application in a highly regulated field, made possible by professional resin printing.

From Prototype to Production Part

Mastering high-performance resin printing models is a science. Success is achieved not by chance, but through the deliberate control of variables across the entire workflow. It requires a balanced understanding of material properties, a detailed approach to print process optimization, and a disciplined execution of precise post-processing protocols. By mastering these advanced techniques, engineers and designers can confidently move beyond simple models. They can unlock the full potential of resin 3D printing as a powerful tool for both high-quality, functional prototyping and the direct production of durable, specialized, end-use parts.