If you’re working on a new product—whether it’s a small consumer gadget, a medical device, or an industrial part—you’ve probably wondered how to turn your design ideas into a physical, testable object. That’s exactly what 3D prototyping services do: they take digital designs (usually from CAD software) and transform them into tangible prototypes using specialized 3D printing or additive manufacturing technologies. These services save you time, money, and frustration by letting you test, refine, and validate your design before moving to mass production. Whether you need a single prototype for a pitch or dozens for user testing, 3D prototyping services tailor their work to your project’s unique needs, materials, and timeline.

What Types of 3D Prototyping Services Are Available?

Not all 3D prototyping services are the same—each technology serves a specific purpose, depending on your prototype’s goals (e.g., testing functionality, showcasing appearance, or simulating durability). Below are the most common types, along with their best uses and real-world examples:

Fused Deposition Modeling (FDM) Services

FDM is the most widely used 3D prototyping technology, ideal for quick, low-cost prototypes. It works by melting a thermoplastic filament (like PLA or ABS) and extruding it layer by layer to build the part.

Best for: Early-stage design testing, functional prototypes (e.g., hinges, enclosures), or educational projects.

Real Case: A startup developing a portable Bluetooth speaker used FDM services to create 10 prototypes of its speaker housing. They tested how easy it was to assemble the internal components (battery, speaker driver) and made 3 rounds of design tweaks—all for under $500 total. Since FDM is fast (each prototype took 8 hours), they finalized the housing design in just 2 weeks.

Stereolithography (SLA) Services

SLA uses a laser to cure liquid resin into solid layers, producing high-detail prototypes with smooth surfaces. It’s perfect for parts that need a polished, near-finished look.

Best for: Visual prototypes (e.g., product demos for investors), small intricate parts (like jewelry or dental models), or prototypes that require tight tolerances.

Key Fact: SLA prototypes can achieve layer heights as small as 0.025mm, making them 5–10x more detailed than standard FDM parts (source: Additive Manufacturing User Program).

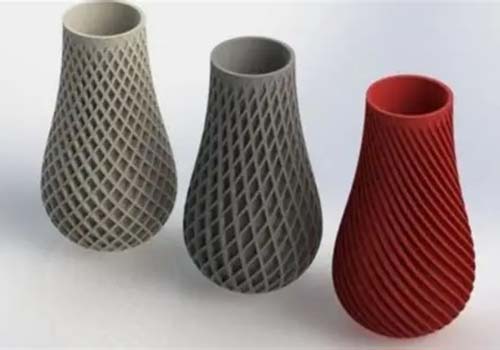

Selective Laser Sintering (SLS) Services

SLS uses a laser to fuse tiny plastic or metal powder particles into a solid part. Unlike FDM or SLA, it doesn’t need support structures, so it’s great for complex geometries (e.g., lattice structures or hollow parts).

Best for: Durable functional prototypes (e.g., gears, brackets), parts that need to withstand stress, or metal prototypes (using materials like stainless steel or titanium).

Real case: An automotive company used SLS services to prototype a lightweight gear for an electric vehicle. The SLS gear was 30% lighter than a traditional metal gear and could withstand the same torque. They tested 5 iterations in 3 weeks, cutting their usual prototyping time by half.

How to Choose the Right 3D Prototyping Service for Your Project

With so many services available, picking the right one can feel overwhelming. Focus on these 5 key factors to ensure your project stays on track, on budget, and meets your goals:

1. Material Compatibility

Not every service offers every material—and the material you choose will make or break your prototype’s usefulness. For example:

- If you need a prototype that mimics a final product’s flexibility (e.g., a phone case), look for services that offer TPU (thermoplastic polyurethane).

- If you need a heat-resistant part (e.g., a component for a coffee maker), choose a service that works with ABS or nylon.

- If you’re prototyping a metal part (e.g., a medical implant), ensure the service offers SLS or DMLS (Direct Metal Laser Sintering) with biocompatible metals.

Pro Tip: Ask the service for material samples before ordering—this lets you test feel, strength, and appearance firsthand.

2. Turnaround Time

How fast do you need your prototype? Most services offer 3 tiers of turnaround:

- Standard: 3–7 business days (best for non-urgent projects).

- Expedited: 1–3 business days (good for tight deadlines, like a investor pitch next week).

- Rush: 24–48 hours (more expensive, but useful for last-minute fixes).

Real case: A student team competing in a design contest needed a prototype of their solar-powered phone charger in 48 hours. They chose a service with rush FDM capabilities, paid a $150 premium, and received the prototype just in time for the contest—they ended up winning second place.

3. Cost and Pricing Transparency

3D prototyping costs vary based on size, material, and technology. Avoid services that hide fees (e.g., setup costs, shipping, or design revisions). Look for:

- Online calculators: Many top services let you upload your CAD file and get an instant quote (e.g., Shapeways, Protolabs).

- Volume discounts: If you need 10+ prototypes, ask about bulk pricing—some services offer 10–20% off for larger orders.

Example Pricing Breakdown:

| Prototype Details | FDM Cost | SLA Cost | SLS Cost (Plastic) |

| Small part (5cm x 5cm x 5cm), PLA | \(20 - \)40 | \(50 - \)80 | \(80 - \)120 |

| Medium part (10cm x 10cm x 10cm), ABS | \(60 - \)100 | \(120 - \)180 | \(200 - \)300 |

4. Quality Assurance and Design Support

Even the best technology won’t save a bad design. Look for services that offer:

- Design reviews: Before printing, they check your CAD file for issues (e.g., missing walls, unprintable geometries) and suggest fixes.

- Quality guarantees: If the prototype doesn’t match your specifications (e.g., wrong color, broken parts), they reprint it for free.

- Technical support: A team you can call or email if you have questions (e.g., “Will this material work for my test?”).

Key Stat: Services with design review processes reduce prototype failure rates by 40% (source: 3D Printing Industry Report 2024).

5. Scalability

If your prototype is successful, will the service help you move to mass production? Some services offer “bridge manufacturing”—small-batch production (100–10,000 parts) using the same technology as prototyping. This saves you time because you don’t have to switch to a new manufacturer.

Example: A toy company used a 3D prototyping service to test a new action figure. Once the design was approved, they used the same service’s bridge manufacturing to make 5,000 units for a limited release. The transition took just 2 weeks, compared to 6 weeks with a traditional manufacturer.

What Are the Key Benefits of Using Professional 3D Prototyping Services?

You might be tempted to buy a consumer 3D printer and do it yourself—but professional services offer advantages that save you time, money, and headaches in the long run:

1. Access to Advanced Technology and Materials

Consumer 3D printers are limited to basic materials (like PLA) and low detail. Professional services have industrial-grade machines that can print with:

- High-performance plastics (nylon, PEEK, TPU).

- Metals (stainless steel, aluminum, titanium).

- Specialized materials (biocompatible resins for medical parts, fire-retardant plastics for electronics).

Example: A medical startup needed a prototype of a surgical tool that could be sterilized. A consumer printer couldn’t handle biocompatible resin—but a professional SLA service printed the tool, which passed sterilization tests on the first try.

2. Faster Turnaround and Less Waste

Professional machines are faster and more reliable than consumer printers. A part that takes 24 hours on a consumer printer might take 4 hours on an industrial FDM machine. Plus, professional services have quality control processes that reduce failed prints—so you don’t waste material or time reprinting.

Key Fact: Professional 3D prototyping services have a failure rate of less than 5%, compared to 20–30% for consumer printers (source: Additive Manufacturing Association).

3. Expertise to Avoid Common Mistakes

Most people don’t know that small design flaws (e.g., a wall that’s too thin, a overhang without support) can ruin a prototype. Professional services have engineers who review your design and fix issues you might miss. For example:

- A startup designed a water bottle with a twist cap—but the cap was too tight to open. The prototyping service suggested widening the cap’s thread by 0.2mm, which fixed the problem without changing the bottle’s look.

4. Cost Savings for Small to Medium Batches

Buying an industrial 3D printer costs \(10,000–\)100,000—plus you have to pay for materials, maintenance, and training. For most projects (1–100 prototypes), it’s cheaper to outsource to a service. Even if you need 50 prototypes, the service’s cost will be a fraction of buying and operating a printer.

Real-World Success Stories: How 3D Prototyping Services Transformed Projects

To see how these services work in practice, let’s look at two diverse case studies—one from a small startup and one from a large corporation:

Case Study 1: Startup Creates a Portable Pet Feeder

Challenge: A small startup called PetPulse wanted to build a portable pet feeder that dispenses food on a schedule. They had a CAD design but needed to test if the feeder was easy to clean, if the food didn’t get stuck, and if the battery lasted long enough.

Solution: They used an FDM prototyping service to print 8 prototypes. The first prototype had a problem: the food chute was too narrow, causing clogs. The service’s engineers suggested widening the chute by 3mm. After 3 more iterations, they had a feeder that worked perfectly.

Result: The startup used the final prototype to pitch to investors, who gave them $200,000 in funding. They then used the same service’s bridge manufacturing to make 1,000 units for a Kickstarter campaign—which sold out in 3 days.

Case Study 2: Aerospace Company Tests a Engine Component

Challenge: A major aerospace company needed to prototype a lightweight bracket for a jet engine. The bracket had to be strong enough to hold 500 pounds but as light as possible to improve fuel efficiency.

Solution: They used an SLS prototyping service that specialized in titanium. The service printed 10 brackets with different lattice structures (to reduce weight). They tested each bracket for strength and weight, then refined the design to find the perfect balance.

Result: The final bracket was 40% lighter than the traditional metal bracket and could hold 600 pounds (exceeding the requirement). The company estimates the bracket will save $500,000 per year in fuel costs for each jet.

Yigu Technology’s Perspective on 3D Prototyping Services

At Yigu Technology, we believe 3D prototyping services are a game-changer for innovation—especially for small businesses and startups that don’t have the resources for in-house manufacturing. We’ve worked with dozens of clients who used 3D prototyping to turn their ideas into products, and the biggest lesson we’ve learned is: early testing = fewer mistakes later. Many clients come to us after trying to skip prototyping, only to spend more money fixing issues in mass production.

We recommend choosing a service that offers end-to-end support—from design reviews to material selection. This ensures your prototype isn’t just a “proof of concept” but a tool that helps you make data-driven decisions about your product. For example, we recently helped a client develop a smart thermostat: using an SLA prototyping service, they tested 4 different button layouts with real users, leading to a design that reduced user confusion by 60%.

In short, 3D prototyping services aren’t just about making a physical object—they’re about de-risking your project, saving time, and building a product that your customers will love.

FAQ About 3D Prototyping Services

1. Do I need a CAD file to use a 3D prototyping service?

Yes—most services require a 3D CAD file (e.g., STL, STEP, or IGES format). If you don’t have a CAD file, many services offer design services to create one for you (for an additional fee). Some also accept 2D drawings and can convert them to 3D.

2. How accurate are 3D prototypes?

Accuracy depends on the technology:

- FDM: ±0.1mm per 100mm (good for functional tests).

- SLA: ±0.05mm per 100mm (excellent for detailed visual prototypes).

- SLS: ±0.15mm per 100mm (great for durable parts).

Most services list their accuracy specs on their website—ask if you need tighter tolerances.

3. Can 3D prototyping services make functional parts (not just models)?

Absolutely. Many technologies (FDM, SLS, DMLS) produce parts that can be used for functional testing—e.g., gears that spin, hinges that move, or parts that withstand heat or pressure. Just make sure to choose the right material for your test (e.g., nylon for impact resistance).

4. How much does a 3D prototype cost?

Costs range from \(20 to \)1,000+ depending on size, material, and technology. A small PLA prototype (5cm x 5cm x 5cm) might cost \(20–\)40, while a large metal prototype could cost $500+. Use the service’s online calculator to get a precise quote.

5. Can I get a prototype in a custom color or finish?

Yes. Most services offer a range of colors (e.g., black, white, red for plastics) and finishes (e.g., smooth, matte, glossy for SLA parts). Some also offer post-processing services like painting, sanding, or annealing (to strengthen parts). Just note that custom finishes may add to the cost and turnaround time.