A precision machining service is a cornerstone of modern manufacturing, providing high-accuracy material removal and shaping processes to create complex, tight-tolerance components for industries ranging from automotive and medical to electronics and energy. Whether you need custom CNC milling, turning, EDM machining, or value-added finishing services, choosing the right precision machining service directly impacts your product’s quality, production timeline, and overall cost-effectiveness. This guide is tailored for procurement managers, product engineers, and business owners seeking to master the essentials of precision machining service—from understanding core processes and capabilities to evaluating service providers and optimizing collaboration. We integrate real-world case studies, verifiable industry data, and expert insights to help you make informed decisions and maximize the value of your precision machining service partnership.

What Is Precision Machining Service? Core Definition & Processes

A precision machining service involves the use of computer-controlled or manually operated machines to remove material from a workpiece with exceptional accuracy, achieving dimensional tolerances as tight as ±0.0001 inches and superior surface finishes. Unlike conventional machining, precision machining service relies on advanced technologies and rigorous process control to ensure consistency across small-batch prototypes, medium-volume production, and high-volume manufacturing runs. The core goal of a precision machining service is to transform raw materials (metals, plastics, composites) into functional, high-precision components that meet strict industry standards and customer specifications.

Key Processes in Precision Machining Service

Top-tier precision machining service providers offer a comprehensive suite of processes to address diverse project needs. Below are the most common and critical processes:

- CNC Machining Services: The backbone of modern precision machining service, CNC (Computer Numerical Control) machining uses pre-programmed software to control machine tools. Key sub-processes include:

- CNC Milling Services: Uses rotating cutting tools to remove material from the workpiece, ideal for creating flat surfaces, slots, holes, and complex 3D geometries. 3-axis, 4-axis, and 5-axis CNC milling are available, with 5-axis offering the highest flexibility for intricate parts.

- CNC Turning Services: Rotates the workpiece while a cutting tool shapes it, perfect for cylindrical components (e.g., shafts, bolts, bushings). Swiss-style CNC turning is specialized for small, high-precision parts with tight tolerances.

- EDM Machining Service: Uses electrical discharge to cut or shape hard materials (tungsten, carbide, hardened steel) without physical contact, ideal for complex shapes and thin-walled components. Key sub-processes include:

- Wire EDM (Wire Cutting EDM) Service: Uses a thin, electrically charged wire to cut precise shapes, suitable for intricate contours and tool and die making.

- Sinker EDM (Ram/Die Sinker EDM) Service: Uses a custom-shaped electrode to create cavities or impressions in the workpiece, ideal for molds and dies.

- Hole-Drilling EDM Service: Specialized for drilling small, deep, and precise holes in hard materials, often used in aerospace and medical applications.

- Precision Grinding Service: Uses abrasive wheels to achieve ultra-smooth surface finishes and tight tolerances, suitable for final finishing of high-precision components (e.g., bearings, gears, medical implants).

Industry Insight: According to a 2026 report by Grand View Research, the global precision machining service market is projected to reach $328.4 billion by 2030, growing at a CAGR of 6.3%. The growth is driven by increasing demand for high-precision components in electric vehicles (EVs), medical devices, and aerospace, with CNC-based precision machining service accounting for 78% of the market share.

Core Capabilities of a Leading Precision Machining Service Provider

When evaluating a precision machining service provider, their capabilities directly determine their ability to meet your project’s unique requirements. Below are the core capabilities to prioritize:

1. Advanced Machining Equipment & Technology

A reliable precision machining service provider invests in state-of-the-art equipment to ensure accuracy and efficiency. Key equipment includes 5-axis CNC milling machines, Swiss-style CNC lathes, high-precision EDM machines, and computerized grinding machines. Additionally, they should use advanced CAD/CAM software (e.g., SolidWorks, Mastercam) for part design, programming, and simulation, reducing errors and optimizing machining processes.

2. Material Expertise

A versatile precision machining service provider should have extensive experience processing a wide range of materials, including:Metals: Aluminum, steel, stainless steel, titanium, Inconel, brass, copper, and exotic alloys (used in aerospace, medical, and energy sectors).Plastics: ABS, PVC, PEEK, nylon, polycarbonate, and Teflon (used in electronics, medical, and consumer goods sectors).Composites: Carbon fiber, fiberglass, and Kevlar (used in aerospace and automotive lightweighting applications).

Material expertise ensures the precision machining service provider can select the right cutting tools, speeds, and feeds to avoid material damage and achieve optimal results. For example, machining titanium requires specialized tools and coolants to prevent work hardening, a challenge that a skilled precision machining service provider can navigate effectively.

3. Prototyping & Production Flexibility

The best precision machining service providers offer flexibility across the entire product lifecycle, from rapid prototyping to high-volume production. Key capabilities include: Rapid Prototyping: Fast turnaround of functional prototypes to validate designs and accelerate product development.Rapid Tooling: Quick production of custom tools to support low-to-medium volume manufacturing runs.End-Use Production: Scalable processes to handle high-volume production with consistent quality and on-time delivery.

Case Study: A medical device startup partnered with a precision machining service provider to develop a prototype for a custom surgical instrument. The provider used rapid CNC prototyping to deliver the first prototype in 5 days, incorporating design feedback to refine the part. Once the design was finalized, the provider scaled to high-volume production (10,000 units/month) using automated CNC turning, ensuring consistent tolerances of ±0.0005 inches and FDA compliance.

4. Quality Control & Inspection

Quality control is non-negotiable for precision machining service providers. Leading firms implement comprehensive inspection processes and use advanced equipment to ensure part quality: Advanced Inspection Equipment: Coordinate Measuring Machines (CMMs), optical comparators, surface roughness testers, and X-ray inspection systems for accurate dimensional and material analysis.Statistical Process Control (SPC): Real-time monitoring of machining processes to identify and correct variations before they affect part quality.Compliance Certifications: Adherence to industry standards such as ISO 9001 (general quality), AS9100 (aerospace), ISO 13485 (medical), and FDA regulations for medical device components.

5. Value-Added Services

Top precision machining service providers offer value-added services to streamline your production workflow and reduce the need for multiple suppliers. Key value-added services include: Finishing Services: Anodizing, electroplating, powder coating, polishing, bead blasting, and black oxide coating to improve part durability, corrosion resistance, and aesthetics.Assembly Services: Integration of machined components into sub-assemblies or finished products, reducing your production time and costs.Design for Manufacturability (DFM) Support: Collaborative engineering to optimize part designs for machining, reducing costs and improving production efficiency.

Advantages of Partnering with a Professional Precision Machining Service

Outsourcing to a professional precision machining service provider offers numerous advantages over in-house machining, especially for businesses without specialized equipment or expertise. Below are the key benefits:

| Advantage | Detailed Explanation | Industry Impact |

| Superior Precision & Quality | Access to advanced equipment and expertise to achieve tight tolerances and high surface finishes that in-house machining may not match. | Critical for medical devices (implants) and aerospace components (turbine blades) where precision directly impacts safety and performance. |

| Cost Savings | Eliminates the need for expensive equipment purchases, maintenance, and skilled labor costs associated with in-house machining. | Small-to-medium enterprises (SMEs) can save 30–50% on production costs by outsourcing to a precision machining service provider. |

| Faster Turnaround Times | Professional providers have optimized processes and dedicated equipment to handle projects quickly, reducing lead times for prototypes and production runs. | Enables businesses to bring new products to market faster, gaining a competitive edge in industries like electronics and consumer goods. |

| Scalability | Ability to scale production from small-batch prototypes to high-volume runs without investing in additional equipment or labor. | Ideal for businesses with fluctuating demand, such as automotive manufacturers during EV production ramp-ups. |

| Access to Specialized Expertise | Teams of skilled engineers and technicians with expertise in material science, machining processes, and industry regulations. | Critical for industries with strict compliance requirements, such as medical (FDA) and aerospace (AS9100). |

| Reduced Risk | Professional providers assume responsibility for quality control and compliance, reducing the risk of defective parts and regulatory penalties. | Minimizes liability for businesses in high-risk sectors like medical and aerospace. |

Industry Applications of Precision Machining Service

Precision machining service is integral to numerous industries, producing critical components that drive innovation and performance. Below are the key industries and their specific applications:

1. Automotive Industry

The automotive industry relies heavily on precision machining service for the production of high-precision components for internal combustion engines, electric vehicles (EVs), and advanced driver-assistance systems (ADAS). Key applications include: EV components: Battery enclosures, motor shafts, and inverter housings (require tolerances of ±0.0005 inches to ensure efficiency).ADAS components: Sensor housings, camera mounts, and radar brackets (require high accuracy to ensure proper functionality).Transmission components: Gears, shafts, and bearings (require tight tolerances to reduce friction and improve durability).

Case Study: A leading automotive manufacturer partnered with a precision machining service provider to produce EV motor shafts. The provider used 5-axis CNC turning to achieve tolerances of ±0.0003 inches, reducing vibration by 25% and improving motor efficiency by 10%. The partnership enabled the manufacturer to scale production to 50,000 units/month, meeting growing EV demand.

2. Medical Industry

In the medical industry, precision machining service is critical for producing components that meet strict biocompatibility and safety standards. Key applications include: Implants: Hip/knee replacements, dental implants, and pacemaker components (made from biocompatible materials like titanium and PEEK).Surgical instruments: Scalpels, forceps, and arthroscopic tools (require ultra-precision for precise tissue manipulation).Diagnostic equipment: MRI machine components, CT scanner parts, and blood glucose monitor sensors (require high accuracy to ensure diagnostic reliability).

A reputable precision machining service provider serving the medical industry must comply with FDA regulations and ISO 13485 standards, ensuring parts are free from contaminants and meet exact specifications.

3. Electronics Industry

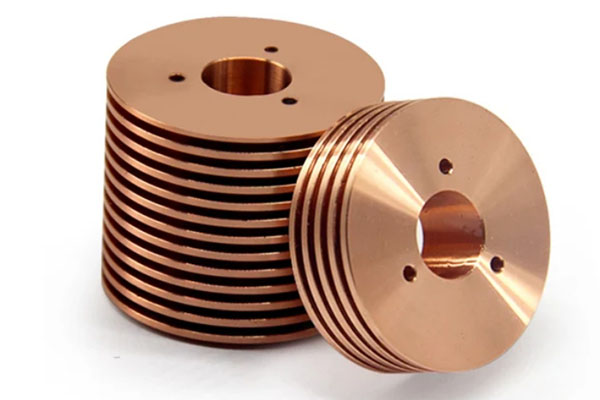

The electronics industry uses precision machining service to produce small, complex components for smartphones, laptops, tablets, and industrial electronics. Key applications include: Electronic enclosures: Smartphone casings, laptop frames, and sensor housings (require lightweight materials and precise fitting).Connectors: USB ports, HDMI connectors, and battery terminals (require tight tolerances to ensure reliable electrical contact).Heat sinks: Components to dissipate heat from electronic devices (require precise fins and channels for optimal thermal performance).

4. Automation & Robotics Industry

The automation and robotics industry depends onprecision machining service to produce components that enable precise movement and control. Key applications include: Robot arms: Joints, gears, and actuators (require high precision to ensure smooth, accurate movement).Conveyor systems: Rollers, bearings, and guides (require durability and precision to handle high-speed automation).Sensors and encoders: Components to measure position and speed (require ultra-precision for accurate feedback).

5. Energy Industry

Precision machining service plays a vital role in the energy sector, producing components for renewable energy (wind, solar) and traditional energy (oil, gas, nuclear) applications. Key applications include: Wind energy: Turbine blades, gearboxes, and shaft components (require high strength and precision to withstand harsh weather conditions).Solar energy: Solar panel mounting brackets and inverter components (require corrosion resistance and precise fitting).Oil and gas: Drill bits, valves, and wellhead components (require durability and precision to handle high pressure and temperature).

How to Select the Right Precision Machining Service Provider: 8 Key Criteria

Selecting the right precision machining service provider is a critical decision that requires careful evaluation of multiple factors. Below are the 8 key criteria to guide your selection process:

1. Technical Capabilities & Equipment

Evaluate the precision machining service provider’s technical capabilities to ensure they can meet your project’s specific needs. Key questions to ask: Do they offer the specific machining processes you need (e.g., 5-axis CNC milling, wire EDM)?Do they have the advanced equipment (CMMs, high-precision CNC machines) required to achieve your tolerances and surface finish requirements?Can they process the materials you need (e.g., titanium, PEEK, composites)?

2. Quality Certifications & Compliance

Quality certifications are a testament to a precision machining service provider’s commitment to consistency and compliance. Prioritize providers with: ISO 9001 certification (general quality management).Industry-specific certifications (AS9100 for aerospace, ISO 13485 for medical, FDA compliance for medical devices).Documented quality control processes and a track record of passing customer audits.

3. Industry Experience & Expertise

Look for a precision machining service provider with experience in your industry and with similar projects. Key indicators of expertise include: Case studies or references from clients in your industry.A team of skilled engineers and technicians with industry-specific knowledge (e.g., medical device regulations, aerospace material requirements).A portfolio of completed projects that demonstrate their ability to handle complex, high-precision components.

4. Production Capacity & Lead Times

Assess the precision machining service provider’s production capacity to ensure they can handle your order volume and meet your lead time requirements. Key considerations: Can they scale production from prototyping to high-volume manufacturing?What are their typical lead times for your project type? Do they offer expedited services if needed?Do they have contingency plans for production disruptions (e.g., equipment breakdowns, supply chain issues)?

5. Cost Competitiveness

While cost should not be the sole deciding factor, it is an important consideration. Evaluate the precision machining service provider’s pricing structure to ensure it aligns with your budget. Look for: Transparent pricing with no hidden fees (e.g., setup fees, material surcharges).Willingness to provide detailed quotes and explain cost drivers (material, labor, tooling, finishing).Ability to optimize designs for manufacturability to reduce costs without compromising quality.

6. Communication & Customer Service

Effective communication is critical for a successful partnership with a precision machining service provider. Look for a provider that: Assigns a dedicated account manager or project engineer to your project.Provides regular updates on production progress (e.g., weekly reports, online project portals).Responds promptly to questions and addresses concerns quickly (ideally within 24 hours).Is willing to collaborate on design optimization and problem-solving.

7. Value-Added Services

Prioritize precision machining service providers that offer value-added services to streamline your production workflow. Key value-added services to look for include finishing (anodizing, electroplating), assembly, and DFM support. These services can reduce the number of suppliers you need to manage and lower overall production costs.

8. Location & Supply Chain Resilience

Consider the precision machining service provider’s location and supply chain resilience. Key factors: Proximity to your business can reduce shipping costs, lead times, and carbon footprint.A diversified supply chain for raw materials to minimize the impact of shortages or price volatility.Compliance with ethical sourcing and sustainability standards (e.g., ISO 14001 for environmental management).

Best Practices for Optimizing Your Precision Machining Service Partnership

Once you’ve selected a precision machining service provider, following these best practices will help ensure a successful collaboration and maximize the value of your partnership:

1. Provide Clear & Detailed Specifications

Supply the precision machining service provider with detailed drawings, 3D models, and specifications (tolerances, surface finish, material requirements, and application details). Use industry-standard file formats (STEP, IGES) and clearly mark critical features. The more detailed your specifications, the less likely there will be misunderstandings or rework.

2. Engage Early in Design for Manufacturability (DFM)

Involve the precision machining service provider’s engineering team early in the design process to conduct a DFM review. A DFM review can identify potential issues (e.g., tight tolerances that are unnecessary, difficult-to-machine geometries) and suggest modifications to reduce costs, improve production efficiency, and enhance part quality. For example, a DFM review might recommend simplifying a complex contour to reduce machining time by 30%.

3. Establish Clear Quality Requirements & Inspection Criteria

Define clear quality requirements and inspection criteria upfront. Work with the precision machining service provider to establish acceptance criteria for first-article inspection (FAI) and in-process inspections. Request regular quality reports to ensure compliance, and consider conducting periodic audits to verify their quality control processes.

4. Maintain Open & Regular Communication

Schedule regular check-ins (weekly or biweekly) with the precision machining service provider to review production progress, address any issues, and provide feedback. Prompt communication can prevent small issues from becoming large problems and ensure the project stays on track. Use a shared project management tool to document decisions and track action items.

5. Plan for Long-Term Collaboration

Building a long-term relationship with a precision machining service provider can lead to better service, improved quality, and cost savings over time. A trusted partner will gain a deeper understanding of your business needs, preferences, and industry requirements, enabling them to proactively suggest improvements to your parts or processes. Consider entering into a long-term contract for recurring projects to secure preferential pricing and lead times.

FAQ About Precision Machining Service

Q1: What is a precision machining service? A1: A precision machining service involves using advanced machines (CNC milling, turning, EDM) to remove material from a workpiece with exceptional accuracy, achieving tolerances as tight as ±0.0001 inches. It produces high-precision components for industries like automotive, medical, electronics, and energy, and includes processes like prototyping, production, and value-added finishing.

Q2: What are the key processes offered by a precision machining service provider? A2: Key processes include CNC machining services (CNC milling, CNC turning), EDM machining service (wire EDM, sinker EDM, hole-drilling EDM), and precision grinding service. Top providers also offer value-added services like anodizing, electroplating, assembly, and DFM support.

Q3: What materials can a precision machining service process? A3: A precision machining service can process a wide range of materials, including metals (aluminum, steel, titanium, Inconel), plastics (ABS, PEEK, nylon), and composites (carbon fiber, fiberglass). The best providers have expertise in selecting the right tools and processes for each material to ensure optimal results.

Q4: How do precision machining service providers ensure quality? A4: precision machining service providers ensure quality through advanced inspection equipment (CMMs, optical comparators), Statistical Process Control (SPC) for real-time process monitoring, and compliance with industry certifications (ISO 9001, AS9100, ISO 13485). They also conduct first-article inspections (FAI) and in-process inspections to verify part accuracy.

Q5: What industries benefit from precision machining service? A5: Key industries include automotive (EV components, ADAS parts), medical (implants, surgical instruments), electronics (device enclosures, connectors), automation & robotics (robot arms, sensors), and energy (wind turbine components, oil and gas parts). Any industry requiring high-precision components can benefit from precision machining service.

Q6: How much does a precision machining service cost? A6: Costs vary based on part complexity, material type, order volume, tolerances, and value-added services. Simple CNC machined parts may cost $10–$100 per unit, while complex components (e.g., medical implants, aerospace turbine blades) can cost $200–$2,000+ per unit. Reputable precision machining service providers offer transparent, detailed quotes.

Q7: What is the typical lead time for a precision machining service? A7: Lead times depend on project complexity and order volume. Rapid prototyping can take 3–7 days, small-batch production (10–100 units) 1–2 weeks, and high-volume production (1,000+ units) 3–6 weeks. Many precision machining service providers offer expedited services for urgent orders, reducing lead times by 40–60%.

Q8: How can I optimize my partnership with a precision machining service provider? A8: Optimize your partnership by providing clear specifications, engaging in DFM reviews early, establishing clear quality requirements, maintaining open communication, and planning for long-term collaboration. These steps reduce rework, lower costs, and ensure on-time delivery of high-quality components.

Discuss Your Projects Needs with Yigu

At Yigu Technology, we are a leading provider ofprecision machining service with over a decade of experience delivering high-accuracy components for clients across automotive, medical, electronics, automation, and energy industries. Our team of skilled engineers and technicians combines state-of-the-art equipment with deep industry expertise to provide tailored precision machining service solutions that meet your unique requirements—whether you need custom CNC milling, turning, EDM machining, or comprehensive value-added services.

Our comprehensive precision machining service capabilities include: Advanced Machining Processes: 5-axis CNC milling, Swiss-style CNC turning, wire EDM, sinker EDM, hole-drilling EDM, and precision grinding, capable of achieving tolerances as tight as ±0.0001 inches.Material Expertise: Processing of all key metals (titanium, Inconel, stainless steel), plastics (PEEK, ABS, polycarbonate), and composites (carbon fiber), with specialized knowledge of industry-specific material requirements.Prototyping & Production Flexibility: Rapid prototyping (3–5 day turnaround), rapid tooling, and scalable end-use production (1–100,000+ units) to support your entire product lifecycle.Rigorous Quality Control: Compliance with ISO 9001, AS9100, and ISO 13485 standards, supported by CMM inspection, SPC, and FDA-compliant processes for medical applications.Value-Added Services: Comprehensive finishing (anodizing, electroplating, powder coating, polishing, bead blasting, black oxide coating), assembly, and DFM support to streamline your production workflow.Supply Chain Resilience: Diversified raw material sourcing and ethical manufacturing practices to ensure consistent delivery, even during supply chain disruptions.

We understand that every precision machining service project has unique challenges—whether it’s achieving ultra-tight tolerances, meeting strict regulatory requirements, scaling production, or adhering to tight lead times. As your partner, we prioritize open communication, transparency, and collaboration to deliver solutions that exceed your expectations. Our dedicated project managers will work closely with you from initial consultation to final delivery, providing regular updates and addressing any concerns promptly.

Contact us today to discuss your precision machining service needs. Let our expertise help you optimize your component design, reduce production costs, and bring high-quality, precision products to market successfully.