Introduction

In the vast landscape of manufacturing, plastic injection molding has emerged as a cornerstone process, powering the creation of countless products that surround us in our daily lives. From the sleek casings of our smartphones to the intricate components within our automobiles, the influence of plastic injection molding is both far - reaching and profound.

The process of plastic injection molding involves injecting molten plastic into a mold cavity, where it cools and solidifies to take on the desired shape. This highly efficient and versatile manufacturing method enables the production of parts with remarkable precision, complex geometries, and high production volumes. However, the success of any plastic injection molding project hinges on one critical decision: choosing the right plastic injection molding company.

Selecting the appropriate plastic injection molding company is not merely a matter of convenience or cost - savings; it is a strategic choice that can have a profound impact on the quality, cost - effectiveness, and timeliness of your product. A reliable and experienced molding partner can be the difference between a product that meets or exceeds market expectations and one that falls short, leading to costly delays, recalls, or a tarnished brand reputation.

In this comprehensive guide, we will explore the multifaceted importance of choosing the right plastic injection molding company. We will delve into the key factors to consider, such as the company's experience, expertise, equipment, quality control measures, and customer service. By the end of this article, you will be equipped with the knowledge and insights necessary to make an informed decision and forge a successful partnership that will drive your product from concept to market with confidence.

Quality Assurance: The Bedrock of Success

Advanced Equipment and Technology

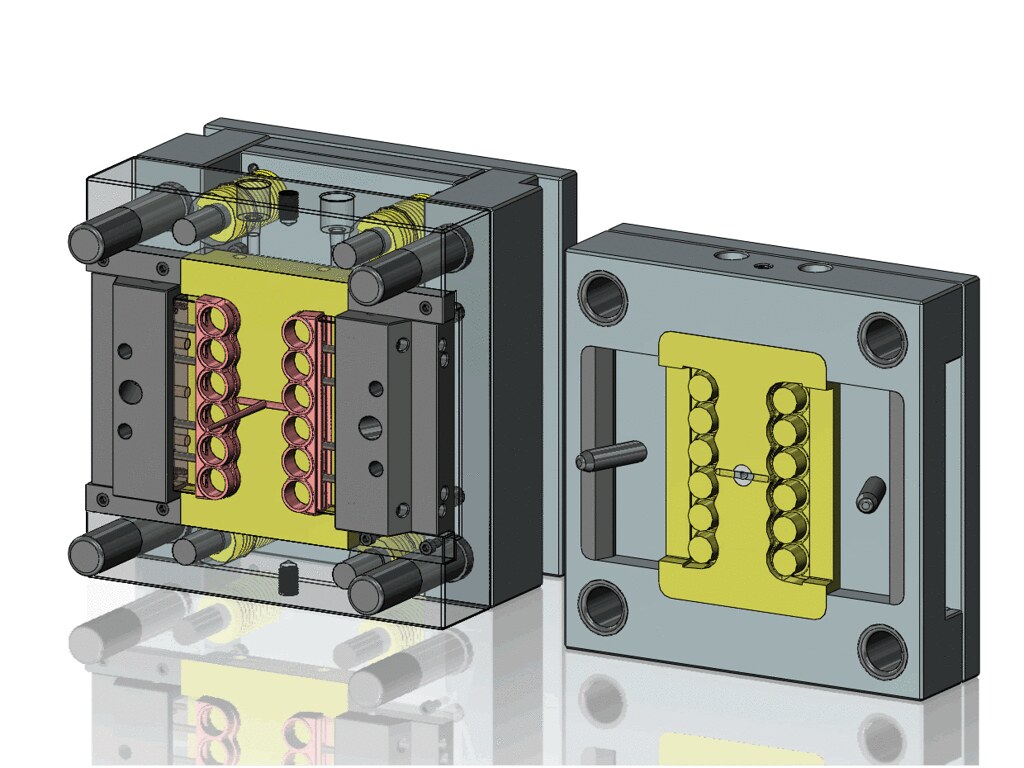

A top - tier plastic injection molding company invests heavily in state - of - the - art equipment and cutting - edge technology. High - precision injection molding machines are the workhorses of the operation. For example, modern injection molding machines can achieve clamping forces ranging from a few tons to over a thousand tons, allowing for the production of both small, intricate parts and large, robust components. These machines are also equipped with advanced control systems that can precisely regulate variables such as injection pressure, speed, and temperature.

In terms of temperature control, the accuracy can reach within ±0.5°C. This level of precision is crucial as even minor temperature fluctuations can lead to variations in the plastic's viscosity, affecting the filling of the mold cavity and ultimately the part's dimensions and quality. Moreover, advanced mold - making equipment, such as Computer Numerical Control (CNC) machining centers, ensures that molds are manufactured with extremely tight tolerances. CNC machines can achieve dimensional accuracies of up to ±0.01mm, which is essential for producing high - precision plastic parts.

Stringent Quality Control Systems

Quality control is not an afterthought but an integral part of the manufacturing process from start to finish. It begins with the meticulous inspection of raw materials. Every batch of plastic resin is thoroughly tested for its physical properties, including melt flow index, density, and molecular weight distribution. For instance, a deviation in the melt flow index can significantly impact the injection process, causing issues like short shots or excessive flash.

During the production process, in - line quality monitoring is employed. Sensors are placed at critical points in the injection molding machine to continuously monitor parameters such as pressure, temperature, and injection volume. If any of these parameters deviate from the pre - set values, the system can automatically adjust the process or alert operators to take corrective action.

After the parts are molded, they undergo a comprehensive final inspection. This includes dimensional inspection using coordinate measuring machines (CMMs), which can accurately measure a part's dimensions to within a few microns. Visual inspections are also carried out to check for surface defects like scratches, pits, or discoloration. Additionally, functional testing is performed if the part has specific mechanical or electrical functions. For example, if the plastic part is a connector for an electronic device, it will be tested for its electrical conductivity and connection stability. Only parts that pass all these rigorous tests are deemed fit for shipment.

Cost - Efficiency: Saving Without Sacrificing

Material Optimization

A proficient plastic injection molding company understands the significance of material optimization in cost - reduction. First and foremost, it involves meticulous material selection. By thoroughly analyzing the requirements of a product, such as its mechanical properties, heat resistance, and chemical resistance, the company can choose the most suitable plastic resin. For example, if a product requires high - strength and heat - resistance, materials like polycarbonate (PC) or polypropylene (PP) with heat - stabilizers might be preferred over less - durable alternatives. This targeted selection ensures that the material not only meets the product's performance needs but also avoids over - specifying, which could lead to unnecessary costs.

Material recycling is another crucial aspect of material optimization. Many plastic injection molding companies have implemented recycling programs for their production waste. In - house recycling of runner systems, sprues, and defective parts can significantly reduce the amount of virgin material needed. For instance, a company might grind up the waste plastic into small pellets and then blend a certain percentage of these recycled pellets with virgin material for future production runs. According to industry studies, on average, a well - managed recycling program can reduce raw material costs by 10 - 20% without sacrificing product quality. This is because modern recycling technologies can ensure that the recycled plastic retains most of its original properties when properly processed. Additionally, some companies even source recycled plastics from external suppliers, further contributing to cost savings and environmental sustainability.

Lean Production Strategies

Lean production strategies are at the heart of cost - efficient plastic injection molding operations. One of the key elements of lean production is the elimination of waste, often referred to as "muda" in the lean manufacturing philosophy. In the context of plastic injection molding, waste can take many forms, such as overproduction, waiting time, excessive inventory, and defects.

Overproduction is a common issue that can tie up resources and increase costs. A lean - oriented molding company carefully aligns production levels with actual customer demand. By implementing just - in - time (JIT) production principles, the company produces only the quantity of parts that are needed, when they are needed. This reduces the need for large storage spaces for excess inventory and minimizes the risk of having obsolete parts. For example, instead of producing a large batch of plastic parts in anticipation of future orders, the company coordinates closely with its customers to receive orders in advance and schedules production accordingly.

Waiting time is another form of waste that can be minimized. This includes the time that machines or workers are idle due to factors like equipment breakdowns, lack of materials, or inefficient scheduling. To address this, companies conduct regular equipment maintenance to prevent breakdowns. They also optimize their production schedules and improve communication between different departments to ensure a smooth flow of materials and operations. For example, by implementing a preventive maintenance program, a company can reduce unplanned equipment downtime by up to 30 - 50%, thereby increasing overall production efficiency.

Excessive inventory is not only costly in terms of storage space but also ties up capital. Lean production encourages keeping inventory levels as low as possible. This is achieved through effective supply chain management, where the company maintains strong relationships with its suppliers to ensure timely delivery of materials. Additionally, the use of inventory management systems helps in tracking inventory levels accurately and restocking only when necessary.

Defects are a major source of waste as they require rework or result in scrapped parts. By implementing strict quality control measures from the start of the production process, as mentioned in the quality assurance section, the number of defects can be significantly reduced. This, in turn, reduces the cost associated with rework and scrap, contributing to overall cost - efficiency.

Production Capacity: Meeting Your Needs

Scalability for Small and Large Orders

A reliable plastic injection molding company should have the flexibility to handle both small - scale and large - scale orders with equal proficiency. For small orders, perhaps for product prototypes or short - run production, the company needs to have efficient setup processes. This includes quick mold changes and the ability to fine - tune the injection molding parameters for a small batch. For example, a startup company developing a new consumer electronic device may only need a few hundred plastic cases for initial market testing. A good molding company will be able to produce these small quantities without charging exorbitant setup fees and with a quick turnaround time.

On the other hand, for large - scale orders, high - volume production capabilities are essential. High - speed injection molding machines with large clamping forces and multi - cavity molds are the key. Consider an automotive parts manufacturer that requires hundreds of thousands of plastic interior components. A plastic injection molding company with a fleet of high - capacity machines and molds with, say, 16 or 32 cavities can significantly increase the production rate. By running multiple shifts and optimizing the production line, they can meet the large - volume demands of such a customer in a timely manner.

Timely Delivery Records

Timely delivery is a critical aspect of any manufacturing service. A reputable plastic injection molding company will have a proven track record of on - time deliveries. For instance, a study of a well - known plastic injection molding company showed that over the past year, it had a 98% on - time delivery rate for its orders. In one case, a major appliance manufacturer had an urgent order for a new line of plastic parts for their upcoming product launch. The molding company, through efficient production scheduling, optimized use of resources, and close communication with its supply chain partners, was able to complete and deliver the order within 15 days, even though the original lead - time estimate was 20 days. This not only saved the appliance manufacturer from potential production delays but also strengthened the relationship between the two companies. Such examples of timely delivery demonstrate a company's reliability and its ability to meet the often - tight deadlines of its customers.

Yigu Technology's Insights

As a non - standard plastic metal products custom supplier, Yigu Technology deeply understands the significance of choosing the right plastic injection molding company. Experience is the foundation. A company with years of industry presence has encountered and overcome various challenges, which equips them with the knowledge to handle complex projects.

Advanced technology is also crucial. Yigu Technology emphasizes that a good injection molding company should adopt the latest molding technologies and equipment to ensure high - quality production. For example, the use of advanced multi - shot injection molding technology can create products with complex structures and high precision.

Moreover, comprehensive service is what sets a great company apart. From the initial product design consultation to after - sales support, every aspect of service matters. Yigu Technology believes that a reliable plastic injection molding company should offer one - stop solutions, helping customers from the design stage to the final product delivery, ensuring a smooth and worry - free production process.

FAQ

How to assess the quality of a plastic injection molding company?

To assess the quality of a plastic injection molding company, first, look at its equipment. State - of - the - art injection molding machines with high - precision control systems can ensure accurate production. For example, machines with precise temperature and pressure control can produce parts with consistent quality. Second, examine its quality control system. A good company will have strict raw material inspection, in - line process monitoring, and comprehensive final inspections, including dimensional, visual, and functional tests. Additionally, check if the company has relevant certifications such as ISO 9001, which indicates its commitment to quality management systems.

What are the common cost - saving measures in plastic injection molding?

Common cost - saving measures include material optimization. Selecting the right plastic resin according to product requirements can prevent over - specifying and save costs. Recycling production waste can also reduce the need for virgin materials, with well - managed recycling programs potentially cutting raw material costs by 10 - 20%. Lean production strategies are another way. Eliminating waste like overproduction, waiting time, excessive inventory, and defects can improve overall efficiency. For example, implementing just - in - time production reduces inventory costs and the risk of obsolete parts.

How can I ensure on - time delivery from a plastic injection molding company?

To ensure on - time delivery, maintain clear and regular communication with the company. Clearly define your delivery schedule and requirements from the start. Include strict delivery - time clauses in the contract, along with penalties for late delivery. Choose a company with a proven track record of timely deliveries. A company that has successfully met tight deadlines for other clients is more likely to deliver your order on time. Additionally, the company's production capacity and its ability to handle potential production issues are also important factors to consider.