Introduction

Definition and Basic Concept of Mini Plastic Gears

Mini plastic gears, as the name implies, are small - sized gears made from plastic materials. These gears typically have a diameter ranging from a few millimeters to around 50 millimeters, making them much smaller than their traditional metal counterparts. They come in various shapes, with the most common being spur gears, which have straight teeth parallel to the axis of rotation, helical gears with angled teeth for smoother operation and higher load - carrying capacity, and bevel gears that are designed to transmit motion between intersecting shafts. In terms of appearance, they are lightweight, often with a smooth surface finish, and can be transparent or colored depending on the type of plastic used. For example, some mini plastic gears made from polycarbonate might have a clear, almost glass - like appearance, while those made from nylon could be opaque and come in colors like black or natural beige.

Significance in the Field of Mechanics and Beyond

In the field of mechanics, mini plastic gears play a crucial role. Their small size allows for the creation of compact mechanical systems, which is essential in modern - day devices where space is at a premium. For instance, in micro - motors used in small appliances like electric toothbrushes, mini plastic gears are used to transfer the rotational motion from the motor to the brush head. This enables the efficient and precise movement required for effective cleaning.

Beyond mechanics, they are also widely used in the electronics industry. In devices such as cameras, the autofocus mechanism often relies on mini plastic gears to adjust the position of the lens elements accurately. Their non - conductive properties make them ideal for use in electronic devices, preventing any unwanted electrical interference. Additionally, in the medical field, mini plastic gears are found in some small - scale medical devices, like certain types of drug delivery systems. Their lightweight nature and the ability to be produced with high precision make them suitable for applications where minimizing the device's weight and ensuring accurate dosing are critical.

The Marvel of Miniature Precision

Design and Manufacturing Precision

Advanced Design Technologies

The design of mini plastic gears is a highly sophisticated process, relying on advanced design technologies such as CAD (Computer - Aided Design) and CAM (Computer - Aided Manufacturing). CAD software allows engineers to create highly detailed 3D models of the gears. For example, with the help of CAD, the tooth profile of a mini spur gear can be designed with extreme precision. Engineers can adjust parameters like the module (a measure of the size of the gear teeth), the number of teeth, and the pressure angle to optimize the gear's performance.

CAM technology then takes the design from the virtual world to the real - world manufacturing process. It generates the tool paths for the manufacturing equipment, ensuring that the physical gears are produced exactly as designed. This integration of CAD and CAM not only improves the accuracy of the design but also significantly reduces the design - to - production time. In a traditional gear design process, it could take weeks to finalize the design and transfer it to production. However, with CAD/CAM, this time can be reduced to a few days or even less, depending on the complexity of the gear.

High - Precision Manufacturing Processes

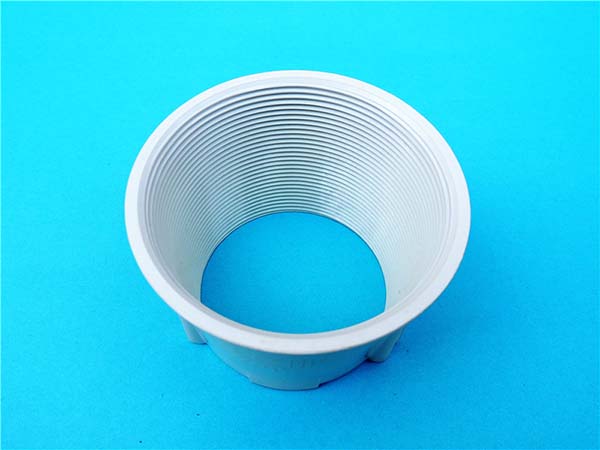

One of the most common and effective manufacturing processes for mini plastic gears is injection molding. In injection molding, plastic pellets are first melted in a heated barrel. The molten plastic is then injected under high pressure into a precisely machined mold cavity that has the shape of the desired gear. The mold is usually made of high - quality steel and is designed with extreme precision. For instance, the tolerances in the mold can be as small as ±0.01 mm.

The advantages of injection molding for mini plastic gears are numerous. It allows for high - volume production with consistent quality. Once the mold is set up, thousands or even millions of gears can be produced with very little variation in size and shape. The process is also relatively fast, with each cycle typically taking only a few seconds to a minute, depending on the size and complexity of the gear. Additionally, injection molding can create gears with complex shapes and features, such as internal gears or gears with integral shafts, which would be very difficult and costly to produce using other methods.

Material Science Behind Mini Plastic Gears

Specialized Plastic Materials

Several specialized plastic materials are commonly used in the production of mini plastic gears. Nylon, for example, is a popular choice. Nylon has excellent mechanical properties, including high tensile strength and good wear resistance. It can withstand a significant amount of stress during the operation of the gear without breaking or deforming easily. Its tensile strength can range from 50 - 100 MPa, depending on the specific type of nylon and any additives used.

Another widely used material is polyoxymethylene (POM), also known as acetal. POM has a low coefficient of friction, which makes it ideal for gears as it reduces the energy required to rotate the gears and also minimizes wear and tear. It also has good dimensional stability, meaning that the shape and size of the gear remain consistent over time, even under different operating conditions.

Material Modifications for Enhanced Performance

To further enhance the performance of mini plastic gears, material modifications are often made. One common method is adding fillers to the base plastic material. For example, adding glass fibers to nylon can significantly increase its strength and stiffness. Glass - filled nylon gears can have a tensile strength that is 30 - 50% higher than unfilled nylon gears. This makes them suitable for applications where higher loads need to be transmitted.

Another modification is the addition of lubricants to the plastic material. Lubricants such as molybdenum disulfide or silicone can reduce the friction between the gear teeth even further, improving the efficiency of the gear system and increasing its lifespan. These material modifications, combined with the careful selection of the base plastic material, allow mini plastic gears to perform optimally in a wide range of applications.

Versatility Unveiled

Applications in Diverse Industries

Automotive Industry

In the automotive industry, mini plastic gears are utilized in various critical systems. For example, in the window - lifting mechanisms of cars, these gears play a fundamental role. They are responsible for smoothly transferring the rotational motion from the electric motor to the window regulator, enabling the seamless raising and lowering of the windows. The small size and lightweight nature of mini plastic gears are highly beneficial here, as they help in reducing the overall weight of the window - lifting assembly, which in turn improves the energy efficiency of the vehicle. Additionally, in some modern car seat adjustment systems, mini plastic gears are used. They allow for precise and quiet adjustments of the seat position, enhancing the comfort of the passengers. These gears can withstand the repeated stress and movement associated with daily seat adjustments, ensuring long - term reliability.

Electronics and Consumer Goods

Mini plastic gears find extensive use in electronics and consumer goods. In small - sized motors used in devices like electric shavers, they are crucial for transmitting the power from the motor to the cutting blades. Their precise operation ensures a smooth and efficient shaving experience. In toys, especially those with moving parts such as robotic toys or wind - up toys, mini plastic gears are commonly employed. For instance, in a wind - up toy car, the gears transfer the stored mechanical energy from the winding mechanism to the wheels, making the car move. In the world of consumer electronics, cameras also rely on mini plastic gears. In autofocus cameras, these gears are used to adjust the position of the lens elements with high precision, allowing the camera to quickly and accurately focus on the subject, whether it's a close - up portrait or a distant landscape.

Medical Devices

In the medical field, mini plastic gears are of utmost importance. In precision pumps used for intravenous drug delivery, these gears ensure the accurate and consistent flow of medications. The high - precision manufacturing of mini plastic gears allows for precise control over the volume of the drug being delivered, which is critical for patient safety and effective treatment. In some surgical instruments, such as minimally invasive surgical robots, mini plastic gears are used in the robotic arms. They enable the delicate and precise movements required during surgery, allowing surgeons to perform complex procedures with greater accuracy and reduced invasiveness. Their biocompatibility, in addition to their mechanical properties, makes them suitable for use in medical devices that come into contact with the human body.

Adaptability to Different Working Conditions

Resistance to Corrosion and Chemicals

Mini plastic gears exhibit excellent resistance to corrosion and chemicals, making them suitable for a wide range of applications. Many plastic materials used in gear production, such as polypropylene (PP) and polyethylene (PE), are highly resistant to common chemicals like acids, alkalis, and solvents. This property makes them ideal for use in industrial applications where exposure to corrosive substances is common. For example, in chemical processing plants, mini plastic gears can be used in pumps or valves that handle corrosive liquids. They can operate for long periods without being damaged by the chemicals, reducing the need for frequent replacements and maintenance. In contrast, metal gears would quickly corrode under such conditions, leading to equipment failure and costly repairs.

Performance in High - and Low - Temperature Environments

Mini plastic gears are designed to perform well in both high - and low - temperature environments, although different materials have different temperature limits. Some high - performance plastics like polyphenylene sulfide (PPS) can withstand high temperatures of up to 200°C. In applications such as automotive engine components where the operating temperature can be very high, PPS - made mini plastic gears can be used. They maintain their mechanical properties and dimensional stability even at elevated temperatures, ensuring the smooth operation of the mechanical systems.

On the other hand, in low - temperature environments, materials like acrylonitrile - butadiene - styrene (ABS) can perform relatively well. In refrigeration systems or Arctic - based equipment, ABS - made mini plastic gears can function properly. However, it's important to note that at extremely low temperatures, the brittleness of some plastics may increase. To counter this, manufacturers may add specific additives to the plastic material to improve its low - temperature performance. These additives can enhance the flexibility and impact resistance of the plastic, allowing the mini plastic gears to operate effectively in cold conditions.

Yigu Technology's Insights

As a non - standard plastic metal products custom Supplier, Yigu Technology highly values the potential of mini plastic gears. They believe that these gears, with their unique advantages such as high precision, lightweight, and excellent adaptability, have a broad application prospect in various industries. Yigu Technology focuses on providing customized solutions for mini plastic gears. They utilize advanced technologies and equipment to ensure the high - precision manufacturing of gears, meeting the diverse needs of different customers. Whether it's for a small - scale medical device or a complex automotive system, Yigu Technology can offer gears that are tailored to specific requirements, in terms of both design and material selection, thus ensuring the best performance and reliability.

FAQ

What are the common materials used for mini plastic gears?

Common materials for mini plastic gears include nylon, polyoxymethylene (POM), polypropylene (PP), and polyethylene (PE). Nylon offers high tensile strength, typically ranging from 50 - 100 MPa, and good wear resistance. POM has a low coefficient of friction, which reduces energy consumption during gear rotation, and excellent dimensional stability. PP and PE are known for their chemical resistance, making them suitable for applications where exposure to corrosive substances is expected.

How to ensure the durability of mini plastic gears?

To ensure the durability of mini plastic gears, first, select the appropriate material based on the application requirements. For example, in high - load applications, glass - filled nylon can be used for its enhanced strength. Second, optimize the gear design. This includes proper tooth profile design to evenly distribute the load and reduce stress concentration. Third, control the manufacturing process strictly. High - precision injection molding with tight tolerances can ensure consistent quality and dimensional accuracy. Regular maintenance, such as lubrication, can also extend the lifespan of the gears.

Can mini plastic gears be used in high - speed rotation applications?

Mini plastic gears can be used in some high - speed rotation applications, but there are limitations. The key factors to consider are the material's mechanical properties and the gear's design. Materials like POM and some high - performance nylons can handle relatively high - speed rotations to a certain extent. However, as the speed increases, issues such as heat generation due to friction and the gear's dynamic balance become more critical. High - speed rotation can cause the gears to heat up, which may lead to material softening and reduced performance. Additionally, if the gears are not well - balanced, vibrations can occur, increasing wear and potentially causing premature failure. So, proper design, material selection, and lubrication are crucial when using mini plastic gears in high - speed applications.

Conclusion

In conclusion, mini plastic gears have proven to be remarkable components in the mechanical and engineering world. Their precision, achieved through advanced design and manufacturing technologies along with specialized materials, allows for their use in applications where the slightest deviation can lead to significant consequences.

The versatility of mini plastic gears, as demonstrated by their wide - ranging applications across industries like automotive, electronics, and medical, and their adaptability to different working conditions, makes them an indispensable part of modern - day product design. As technology continues to advance, we can expect to see further improvements in the performance of mini plastic gears. New materials may be developed, offering even better mechanical properties, chemical resistance, and temperature tolerance. Manufacturing processes will likely become even more precise and efficient, enabling the production of gears with even smaller dimensions and more complex geometries.