What is a 3D Print Engine Model?

A 3D print engine model is a physical replica of an engine that is created using 3D printing technology. This process involves taking a digital design of an engine and using a 3D printer to build the model layer by layer, typically with materials such as plastic, resin, or even metal in some advanced cases.

Unlike traditional engine models made through casting, machining, or injection molding, 3D printed engine models offer unique advantages. Traditional manufacturing methods often require expensive molds and tooling, and they can be time - consuming for complex geometries. For example, creating a complex internal combustion engine model with traditional methods might need multiple molds for different parts, and any design changes would mean costly mold modifications. In contrast, 3D printing allows for rapid prototyping. The digital design can be easily adjusted, and a new model can be printed in a relatively short time, sometimes within a few hours to a few days, depending on the size and complexity of the model.

These 3D printed engine models serve various purposes. They can be used for educational purposes, such as in schools and universities to help students better understand engine structures and functions. In the automotive and aerospace industries, they are used for design validation and testing. Engineers can print a 3D model of a new engine design to test its aerodynamics, fitment, or to conduct stress analysis in a more cost - effective way compared to building a full - scale, expensive prototype. Additionally, 3D print engine models are popular among hobbyists and collectors, who can create highly detailed replicas of rare or iconic engines.

The Working Principle of 3D Printing for Engine Models

Layer - by - Layer Construction

The core of 3D printing for engine models lies in its layer - by - layer construction method. Most 3D printers operate in a two - step process for each layer. First, a special glue is sprayed onto the build area in a pattern corresponding to the cross - section of the engine model at that layer. The droplets of this glue are tiny and have low diffusivity, ensuring precise placement. Then, a layer of powder, which could be plastic, metal, or ceramic powder depending on the material requirements, is evenly spread over the area. The powder particles bond immediately when they come into contact with the glue, while the areas without glue remain loose. This process is repeated layer by layer. For instance, a small - scale 3D printed engine model with a height of 10 centimeters might require hundreds of these layers, with each layer being as thin as 0.01 - 0.1 millimeters, depending on the printer's resolution.

There are two main types of 3D printing technologies for engine models: stacking and sintering. Stacking technology is mainly used for materials like plastics and silicone. It requires materials that can quickly undergo a curing reaction. For example, in fused deposition modeling (FDM), a common 3D printing technology, a plastic filament is melted and extruded layer by layer to form the model. Sintering technology, on the other hand, uses high - energy sources like lasers to heat and sinter metal or ceramic powders. Selective laser sintering (SLS) is a popular sintering - based 3D printing method. In SLS, a laser scans the powder bed, melting and fusing the powder particles together according to the model's cross - sectional design. The main difference between them is the materials they can handle and the energy source used for the formation of layers. Stacking is more suitable for low - melting - point materials, while sintering can process high - melting - point materials such as metals, enabling the production of more heat - resistant and high - strength engine model components.

Material Usage

A variety of materials can be used for 3D printing engine models, each with its own set of advantages and limitations.

- Metal Powders: Metals like aluminum, titanium, and stainless - steel powders are popular choices, especially for high - performance engine models. Aluminum powder, for example, offers a high strength - to - weight ratio. It is lightweight, which is beneficial for applications where reducing weight is crucial, such as in aerospace - related engine models. Titanium powder, on the other hand, has excellent heat resistance and corrosion resistance. Engine models printed with titanium powder can withstand high - temperature environments, making them suitable for representing engines in extreme - condition applications. However, metal powders are generally more expensive, and the 3D printing process with metal powders often requires high - end equipment and complex post - processing steps, such as heat treatment to improve the mechanical properties of the printed parts.

- Plastics: Common plastics used in 3D printing engine models include acrylonitrile butadiene styrene (ABS) and polylactic acid (PLA). ABS is a strong and durable plastic. It has good impact resistance, making it suitable for creating engine models that need to withstand some mechanical stress during handling or display. For example, an engine model for educational purposes, which might be passed around in a classroom, could be made of ABS. PLA is a biodegradable plastic, which is more environmentally friendly. It is relatively easy to print with and has a lower melting point compared to ABS. PLA is often used for creating detailed, non - functional engine models for display or as prototypes for initial design evaluations. However, PLA is more brittle than ABS and has lower heat resistance, so it may not be suitable for representing engines that operate at high temperatures.

Considerations When 3D Printing an Engine Model

Model Design Optimization

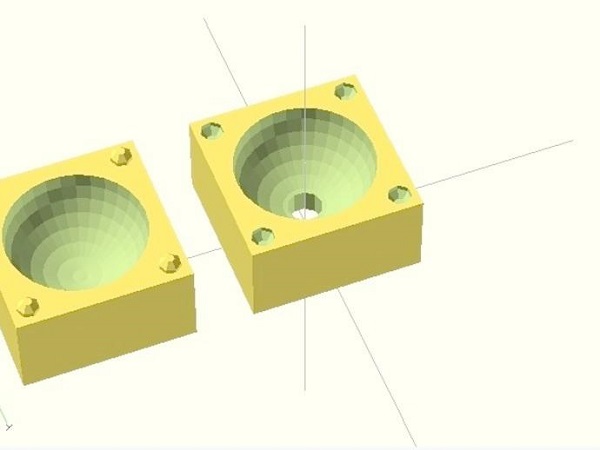

Before 3D printing an engine model, optimizing the model design is crucial. One important aspect is to avoid overhangs or large unsupported areas. For example, if a part of the engine model has a long, horizontal projection without any support from below, it can cause problems during the 3D printing process. In FDM 3D printing, overhangs may result in sagging or even complete failure of that part as the molten plastic filament has no support to hold it in place while it cools and solidifies. To solve this, designers can either add support structures in the digital model. These supports can be designed to be easily removable after printing, such as using a different material for the supports that can be dissolved or broken off without damaging the main model.

Another key point is optimizing the wall thickness. The wall thickness should be consistent throughout the model as much as possible. In a 3D printed engine model, if the wall thickness varies significantly, it can lead to uneven cooling during the printing process. For instance, a thick - walled section will take longer to cool compared to a thin - walled section. This difference in cooling rates can cause internal stresses in the model, leading to warping or cracking. A good rule of thumb is to keep the wall thickness within a range that is suitable for the chosen 3D printing technology and material. For most common 3D printing plastics like PLA, a wall thickness of 1 - 3 mm is often recommended.

Printer and Material Selection

Selecting the right 3D printer and material is essential for a successful engine model print. When it comes to printers, consider the build volume. If you are printing a large - scale engine model, you will need a 3D printer with a sufficient build volume to accommodate the entire model. For example, a small desktop 3D printer with a build volume of 200 x 200 x 200 mm may not be suitable for printing a full - size V8 engine model.

Printer resolution is another crucial factor. High - resolution printers can produce more detailed engine models. For an engine model where you want to show fine details such as the texture of the engine block or the small grooves in the pistons, a printer with a high - resolution (e.g., 50 - 100 microns layer height) would be ideal. However, high - resolution printers are often more expensive.

In terms of materials, if you need a model for functional testing, materials with high strength and heat resistance are preferred. For example, if you are printing an engine model to test the flow of coolant or lubricant, a heat - resistant plastic like polycarbonate (PC) or a metal - based material could be a good choice. PC has excellent mechanical properties and can withstand higher temperatures compared to common 3D printing plastics like PLA. On the other hand, if the engine model is mainly for display purposes, materials like PLA can be sufficient. PLA is easy to print, comes in a wide range of colors, and is relatively inexpensive, making it a popular choice for creating visually appealing display models.

Yigu Technology's Viewpoint

As a non - standard plastic metal products custom supplier, Yigu Technology recognizes the significant impact of 3D print engine models on product development and production. 3D printed engine models enable faster design iterations. For example, when developing a new engine - related product, instead of waiting weeks for traditional prototypes, a 3D printed model can be ready in a few days. This allows our R & D team to quickly test concepts, make design adjustments, and move forward in the product development cycle more efficiently.

FAQ

1. What materials are best for 3D printing an engine model?

For 3D printing engine models, different materials suit various requirements. High - temperature - resistant components can be printed with metal powders like nickel - based superalloys or titanium alloys. These materials can withstand high temperatures, which is crucial for parts exposed to heat during engine operation. For non - critical components or display - only models, engineering plastics such as ABS or polycarbonate are good options. ABS offers strength and durability, while polycarbonate has better heat resistance compared to many other plastics.

2. How accurate can a 3D printed engine model be?

Common 3D printers can achieve a resolution of up to 600 DPI (dots per inch), with a layer thickness as low as 0.01mm. However, the actual accuracy depends on the type of 3D printer and the material used. For example, SLA (Stereolithography Apparatus) printers, which use light - curing resin, can generally produce more accurate models compared to FDM (Fused Deposition Modeling) printers that extrude molten plastic filaments. The accuracy can also be improved by adjusting printing parameters, such as slower printing speed and more precise calibration of the printer.

3. Can I 3D print a functional engine model?

It is possible to 3D print some functional engine models, especially for small - scale or low - power applications. For instance, some hobbyists have printed small - scale internal combustion engines that can run on a limited basis. However, due to material limitations (most 3D - printed plastics have lower strength and heat resistance compared to traditional engine materials) and the current state of 3D printing technology, these models are still far from equivalent to full - scale, high - performance real - world engines in terms of power output, durability, and efficiency.