Introduction

In the dynamic realm of modern manufacturing, two technologies stand out prominently: 3D printing and injection molding. But what exactly are they, and why is the combination of 3D printing molds for injection molding so crucial?

3D printing, also known as additive manufacturing, is a revolutionary process that creates three - dimensional objects from a digital file. It works by layering materials, such as plastics, metals, or ceramics, one on top of another until the desired object is formed. This technology has opened up a world of possibilities, allowing for the creation of complex geometries that were previously difficult or impossible to achieve with traditional manufacturing methods.

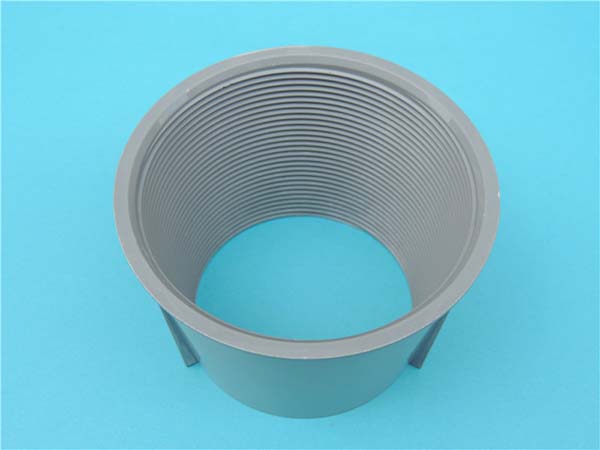

Injection molding, on the other hand, is a widely used manufacturing process for producing parts in high volumes. It involves injecting molten material, typically plastic, into a mold cavity. Once the material cools and solidifies, the mold is opened, and the finished part is ejected. Injection molding is known for its efficiency, precision, and the ability to produce consistent, high - quality parts.

When we combine 3D printing and injection molding by using 3D - printed molds for injection molding, we unlock a host of benefits. For instance, 3D - printed molds can be created much faster than traditional molds, which are often machined from metal. This significantly reduces the lead time for new product development. Additionally, 3D printing allows for the creation of highly customized molds with complex internal structures, enabling the production of parts with intricate features. However, this combination also comes with its own set of challenges, such as material compatibility and the durability of 3D - printed molds. In the following sections, we will delve deeper into the advantages, challenges, applications, and future prospects of 3D printing molds for injection molding.

The Basics of 3D Printing Molds for Injection Molding

What is 3D Printing?

3D printing, or additive manufacturing, is a process that creates three - dimensional objects by layering materials based on a digital model. It starts with a CAD (Computer - Aided Design) file, which is sliced into thin layers by specialized software. The 3D printer then reads these sliced files and deposits the material layer by layer. For example, in Fused Deposition Modeling (FDM), one of the most common 3D - printing techniques, a spool of thermoplastic filament is fed into an extruder. The extruder heats the filament until it becomes molten and then deposits it in precise patterns according to the sliced model, gradually building up the object. Another technology, Stereolithography (SLA), uses a vat of liquid resin. A laser traces the cross - section of each layer onto the surface of the resin, curing it and solidifying the layer. This process repeats until the entire 3D object is formed.

How Does it Apply to Injection Molding?

In traditional injection molding, molds are typically machined from metal blocks. This process involves multiple steps such as milling, drilling, and grinding to create the cavity and core of the mold. However, with 3D - printed molds for injection molding, the process becomes more flexible and faster.

The Process of 3D - Printed Mold for Injection Molding

- Design Phase: First, the design of the injection - molded part is created in a CAD software. Then, the mold design, which includes the cavity, core, runner system, and ejection mechanism, is developed. The advantage of 3D - printing in this stage is that complex internal geometries, such as conformal cooling channels, can be easily designed. These conformal cooling channels follow the shape of the part being molded, providing more efficient cooling compared to traditional straight - drilled cooling channels.

- 3D Printing the Mold: Once the mold design is complete, it is sent to the 3D printer. The printer deposits the chosen material layer by layer to build the mold. For plastic 3D - printed molds, materials like high - temperature - resistant polymers can be used. Metal 3D - printing technologies, such as Selective Laser Melting (SLM), can also be used to create metal molds with high precision and strength.

- Assembly and Finishing: After printing, the 3D - printed mold components may need some post - processing. This can include removing support structures (if any), sanding, and polishing to achieve the desired surface finish. Then, the mold is assembled, and it is ready to be used in the injection - molding machine.

- Injection Molding: Molten plastic is injected into the 3D - printed mold at high pressure. The plastic fills the cavity, takes the shape of the part, cools down, and solidifies. Once solid, the mold is opened, and the finished injection - molded part is ejected.

For example, a small - scale manufacturing company might use a 3D - printed mold to quickly produce prototypes of a new plastic product. Instead of waiting weeks for a traditionally - machined metal mold, they can have a 3D - printed mold ready in a matter of days, significantly reducing the time to market for their new product.

Yigu Technology's Perspective

As a non - standard plastic metal products custom Supplier, Yigu Technology sees great potential in 3D printing molds for injection molding. In custom - made product scenarios, 3D - printed molds offer distinct advantages. They allow for rapid prototyping, enabling us to quickly test and iterate on new product designs. For example, when developing a unique plastic component for a client in the aerospace industry, the ability to quickly create a 3D - printed mold reduces the lead time from weeks to days.

However, we also face challenges. The durability of some 3D - printed mold materials, especially when dealing with high - volume production, can be a concern. Material compatibility between the 3D - printed mold and the injected plastic also needs to be carefully considered. To address these issues, we invest in research to select the most suitable 3D - printing materials and optimize the mold design. We also collaborate closely with material suppliers to develop new materials that can better meet the requirements of injection - molding molds.

FAQ

1. Is 3D printed mold suitable for large - scale production?

3D printed molds can be suitable for large - scale production to some extent, but it depends on several factors. For low - to medium - volume production runs (usually up to a few thousand parts), 3D printed molds can be a great option. They can reduce the lead time for mold production, which is beneficial when quick product launches are required. However, for extremely high - volume production (tens of thousands or more parts), traditional metal - machined molds often have an edge. 3D printed molds may experience wear and tear more quickly, especially if made from certain plastic materials. Some high - temperature - resistant polymers used in 3D printed molds can withstand around 100 - 500 injection cycles before significant degradation, while a well - made traditional steel injection mold can endure hundreds of thousands of cycles. But with the development of 3D printing materials and technologies, such as the use of metal 3D - printed molds with high - strength alloys, the applicability of 3D printed molds in large - scale production is gradually increasing.

2. What materials can be used for 3D printing injection molds?

- Plastics:

- High - temperature - resistant polymers: Materials like Polyetherimide (PEI) can withstand high temperatures during the injection - molding process. PEI has a high glass - transition temperature, typically around 217°C, making it suitable for molds where the injected plastic has a high melting point. It also has good mechanical properties, providing decent strength for the mold.

- Epoxy - based resins: These resins can be 3D printed and offer good dimensional stability. They are relatively easy to print and can be used for making molds for low - to medium - temperature injection - molding applications.

- Metals:

- Stainless steel: 3D - printed stainless - steel molds offer high strength, corrosion resistance, and durability. They can be used for long - term, high - volume production runs. For example, molds made from 316L stainless steel can endure the high pressures and temperatures of injection molding while maintaining their shape and integrity.

- Aluminum alloys: Aluminum 3D - printed molds are lightweight and have good thermal conductivity. This allows for efficient heat transfer during the injection - molding process, reducing cooling times. Alloys like AlSi10Mg are commonly used in 3D - printed aluminum molds.

3. How accurate are 3D printed injection molds?

The accuracy of 3D printed injection molds depends on the 3D - printing technology and the post - processing methods. In general, most industrial 3D printers can achieve an accuracy of ±0.1 - 0.3 mm for larger - sized molds (objects with dimensions in the range of several centimeters to a few decimeters). For example, in Selective Laser Sintering (SLS) 3D - printing technology, which is often used for making molds, the layer thickness can be as low as 0.05 - 0.15 mm, contributing to relatively high precision. High - end 3D printers using technologies like Digital Light Processing (DLP) can achieve even higher accuracies, sometimes down to ±0.01 - 0.05 mm for smaller, more intricate molds. However, it's important to note that post - processing steps such as sanding, polishing, and CNC machining can further improve the accuracy and surface finish of the 3D - printed mold, bringing it closer to the tight tolerances required for high - precision injection - molding applications.