Definition and Basics of Printing Mould

A printing mould, also known as a printing plate, is a crucial tool in the printing industry. It serves as a master pattern from which text and images are transferred onto various substrates, such as paper, fabric, or plastic. The history of printing moulds dates back centuries, with the development of different techniques revolutionizing the way information and art are reproduced.

In traditional printing, the mould could be made of materials like wood, metal (such as copper or zinc), or stone. For instance, in woodblock printing, which has a long history in China, the design is carved into a wooden block, with the non - printing areas being removed. The block is then inked, and the image is transferred onto paper by pressing. This simple yet effective method was used to print religious texts, artworks, and more. Metal plates, on the other hand, offered greater durability and precision. They were often used in intaglio printing, where the design is engraved or etched into the metal surface. Ink is then filled into these recessed areas, and when the plate is pressed against the paper, the image is transferred.

Modern printing moulds have evolved significantly with the advent of digital technology. Computer - to - plate (CTP) systems have replaced many traditional plate - making methods. In CTP, digital files are directly transferred onto a printing plate, eliminating the need for film. This not only speeds up the plate - making process but also improves the quality and accuracy of the printed image. For example, in offset printing, one of the most common printing methods today, the CTP - produced plates are used to transfer the inked image to a rubber blanket and then onto the paper, resulting in high - quality prints with sharp details and accurate color reproduction.

Types of Printing Moulds

1. Traditional Printing Moulds

- Relief Printing Moulds: In relief printing, the printing surface is raised above the non - printing areas. Woodcut printing is a classic example. The design is carved into a wooden block, with the parts to be printed remaining raised. For instance, early religious texts and artworks were often printed using woodcut relief moulds. Another type is the metal relief mould, usually made of copper or zinc. These are more durable than wood and can achieve higher precision. They are often used for printing high - end packaging, such as luxury product boxes. The working principle is straightforward: ink is applied to the raised surface of the mould, and then the substrate (like paper) is pressed against it, transferring the ink and creating the printed image. However, the process of carving or engraving these moulds is time - consuming, and the moulds can be easily damaged over time.

- Intaglio Printing Moulds: Intaglio printing is the opposite of relief printing. The design is engraved or etched into the plate, creating recessed areas. When printing, ink is filled into these recesses, and the excess ink is wiped off the surface of the plate. Then, under high pressure, the ink in the recesses is transferred to the paper. Copperplate engraving is a well - known intaglio method. It is highly valued for its ability to produce fine lines and detailed images, making it suitable for printing art reproductions, banknotes, and high - end invitations. The quality of intaglio prints is characterized by their rich, deep colors and the tactile feel of the ink on the paper. But the production of intaglio moulds is complex and expensive, and the printing speed is relatively slow.

- Planographic Printing Moulds: Planographic printing, like offset lithography, uses a flat - surface printing plate. The key to this method is the principle of "oil and water do not mix." The printing areas on the plate are made hydrophobic (water - repelling) and oleophilic (oil - attracting), while the non - printing areas are hydrophilic (water - attracting) and oleophobic (oil - repelling). First, the plate is moistened with water, which is absorbed by the non - printing areas. Then, ink is applied, and it adheres only to the printing areas. The inked image is transferred from the plate to a rubber blanket and then onto the paper. Offset lithography is widely used in the printing industry for newspapers, magazines, and books due to its high - speed and cost - effective production capabilities. It can reproduce a wide range of colors accurately and handle large - volume printing jobs efficiently.

2. Modern Digital Printing Moulds

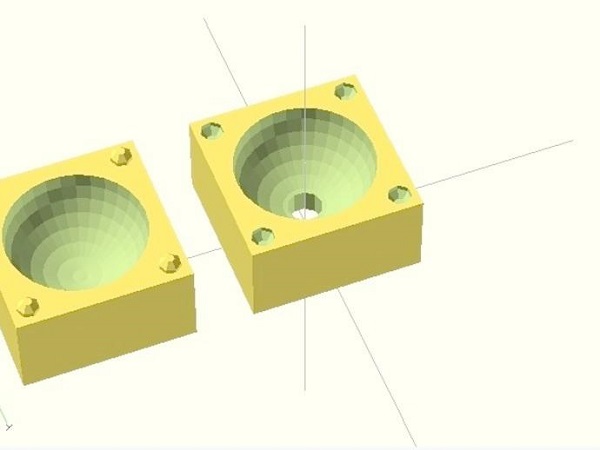

- 3D Printing Moulds: 3D printing has revolutionized the mould - making process. With 3D printing, moulds can be created layer by layer from digital designs. This allows for highly complex and customized mould shapes that were previously difficult or impossible to achieve with traditional methods. For example, in the manufacturing of intricate jewelry casting moulds or customized industrial parts moulds, 3D printing offers unparalleled flexibility. The production speed is relatively fast, especially for small - batch production. It also reduces the need for extensive tooling and setup, saving both time and cost. Additionally, 3D printing moulds can be made from a variety of materials, including plastics, resins, and even metals, depending on the application requirements.

- Digital Inkjet Printing Moulds: Digital inkjet printing moulds are another innovation in the printing industry. In this process, ink is directly ejected onto the substrate in a precise pattern controlled by a digital file. It is highly suitable for short - run printing jobs and personalized printing. For example, in the production of customized T - shirts, where each shirt may have a different design, inkjet printing moulds can quickly and accurately transfer the design. The advantage of digital inkjet printing moulds lies in their ability to produce high - quality prints with vivid colors and sharp details. They also enable on - demand printing, reducing inventory costs as products can be printed only when needed.

Key Factors in Choosing a Printing Mould

1. Printing Volume

The printing volume is a fundamental factor in determining the choice of a printing mould. For high - volume printing, durability and efficiency are crucial. Traditional metal - based moulds, such as those used in offset printing, are often preferred. For example, in newspaper printing, where millions of copies are printed daily, metal offset plates can withstand the high - speed and continuous printing process. They can maintain their shape and printing quality over a large number of impressions, reducing the need for frequent plate replacement. According to industry statistics, a well - maintained metal offset plate can be used for hundreds of thousands of impressions in high - volume newspaper printing.

On the other hand, for small - volume printing jobs, flexibility becomes more important. Digital printing moulds, like those used in inkjet printing, are a better option. They can be quickly set up for different designs without the need for extensive pre - press preparation. For instance, a small - scale local business that needs to print a few hundred personalized marketing brochures can use inkjet printing moulds. The setup time is minimal, and the cost per unit is reasonable for small quantities, making it a cost - effective and flexible solution.

2. Printing Quality Requirements

When it comes to printing quality requirements, different moulds offer distinct advantages. For high - precision image printing, such as in art book reproduction or high - end product packaging, intaglio printing moulds are highly recommended. The recessed areas in intaglio plates can hold a large amount of ink, resulting in rich, detailed, and high - contrast images. The fine lines and smooth gradients achieved in intaglio printing are difficult to replicate with other methods. For example, the reproduction of famous oil paintings in art books often uses intaglio printing to capture every brushstroke and color nuance accurately.

In contrast, for general - purpose printing with moderate quality requirements, like office document printing or standard - grade magazine printing, planographic printing moulds used in offset lithography are sufficient. Offset lithography can achieve good color accuracy, sharp text, and clear images at a relatively low cost. It can reproduce a wide gamut of colors and handle various types of substrates, making it suitable for mass - market printing needs.

3. Cost Considerations

Cost is a multi - faceted factor in choosing a printing mould. The initial procurement cost of a mould can vary significantly. Traditional metal - engraved moulds, especially those for intaglio printing, can be very expensive due to the complex manufacturing process. For example, a high - quality copperplate for intaglio printing can cost several hundred dollars or more, depending on its size and complexity. In comparison, digital 3D - printed moulds may have a lower initial cost, especially for simple designs, as the 3D printing process can be more cost - effective for small - batch production.

The lifespan of the mould also affects the overall cost. Durable metal moulds can have a long lifespan, which reduces the long - term cost per impression. However, they may require regular maintenance, such as cleaning, polishing, and sometimes re - engraving, which adds to the cost. Digital printing moulds, while having a lower initial cost, may need to be replaced more frequently, especially if they are made of less - durable materials. For example, a 3D - printed plastic mould used in a small - scale manufacturing process may last for only a few hundred uses before it starts to show signs of wear and needs to be replaced.

Maintenance costs are another aspect. Some moulds, like traditional relief printing woodblocks, need to be carefully stored and protected from humidity and pests to prevent warping and damage. Metal moulds may require special cleaning solutions and equipment to maintain their printing quality. Digital printing moulds may need software updates and occasional calibration to ensure accurate printing. Considering all these cost factors is essential to make an informed decision on the most cost - effective printing mould for a particular printing job.

Yigu Technology's Perspective

As a non - standard plastic metal products custom Supplier, Yigu Technology has in - depth expertise in the field of printing moulds. We understand that each printing project has unique requirements. Whether it's a small - scale, highly customized job or a large - volume production, our professional team can provide tailored solutions.

We are equipped with advanced manufacturing equipment, which enables us to produce high - precision printing moulds with complex designs. Our quality control system ensures that every mould leaving our factory meets the highest standards. By closely collaborating with our clients, we can accurately translate their ideas into high - quality printing moulds, helping them achieve excellent printing results in various applications, from packaging to art reproduction.

Our commitment to innovation and customer satisfaction drives us to continuously improve our services and product quality in the printing mould sector.

FAQ

Q1: How long does it take to produce a printing mould?

A: The production time depends on the type and complexity of the mould. Traditional metal - engraved moulds may take longer, usually 1 - 2 weeks for a simple one, while 3D - printed moulds can be produced within a few days for small - scale and less - complex designs.

Q2: Can I use the same printing mould for different types of printing materials?

A: It depends on the mould material and design. Some moulds, like those made for offset printing, are versatile and can be used with a variety of paper types. However, if you want to print on different substrates such as fabric or plastic, you may need to adjust the mould or use a different one, as the ink adhesion and printing pressure requirements vary.

Q3: What maintenance is required for a printing mould?

A: For metal moulds, regular cleaning with appropriate solvents to remove ink residue is necessary. They may also need occasional polishing to maintain a smooth surface. Digital printing moulds may require software updates and calibration to ensure accurate printing. Wooden moulds should be stored in a dry environment to prevent warping.