Introduction to Sintering

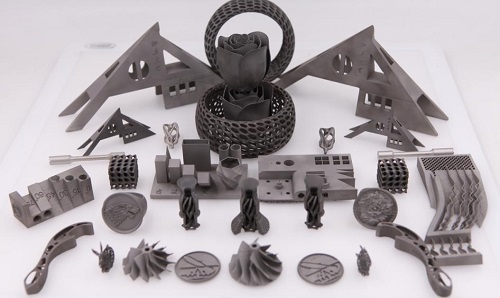

Sintering is a vital process in additive manufacturing, particularly in powder-based 3D printing technologies. It involves heating powdered materials to just below their melting point, causing the particles to fuse together into a solid structure without fully melting. This technique is essential for creating strong, durable, and complex objects that retain high levels of detail. The importance of sintering in 3D printing lies in its ability to produce intricate geometries with minimal support structures, making it particularly useful for industries that require functional prototypes and end-use parts.

Definition and Process

Sintering refers to the process of compacting and bonding particles of a material through heat or pressure, without causing the material to melt completely. In 3D printing, sintering is typically achieved through techniques like Selective Laser Sintering (SLS) and Direct Metal Laser Sintering (DMLS). Both methods use a laser to heat and fuse the particles of a powdered material, layer by layer, to build up the desired part.

Here’s a step-by-step breakdown of how sintering works in 3D printing:

- Model Creation: A 3D model is designed using CAD software, which is then sliced into thin layers.

- Powder Bed Setup: A layer of fine powder (either polymer or metal) is spread across a build platform.

- Laser Application: A high-powered laser selectively heats areas of the powder, causing it to fuse together. This process is repeated layer by layer until the part is fully formed.

- Cooling and Removal: Once the part is complete, it is allowed to cool and solidify. Any excess powder is then removed, and the part is ready for further processing or use.

This sintering process allows the creation of parts with high strength and fine detail, often requiring little to no support structures.

Comparison with Other 3D Printing Techniques

While sintering is a popular technique in 3D printing, it is one of several available methods, each suited for different applications:

Fused Deposition Modeling (FDM)

- Process: FDM involves extruding melted filament (usually thermoplastic) through a nozzle and building up layers.

- Limitations: FDM parts often require support structures and can struggle with complex geometries. The parts also typically have lower resolution and strength compared to sintered parts.

Stereolithography (SLA)

- Process: SLA uses a UV laser to cure a liquid resin, solidifying it layer by layer.

- Limitations: SLA offers high-resolution prints but is often limited by material properties and durability.

Selective Laser Melting (SLM)

- Process: Like sintering, SLM uses a laser to melt metal powders, but unlike sintering, it fully melts the powder into a liquid state.

- Difference: SLM results in parts that are denser and stronger but can also suffer from thermal stresses and warping due to the higher temperatures used.

Advantages of Sintering Over Other Techniques

- Complex Geometries: Sintering, particularly SLS, excels at creating complex shapes with minimal or no support structures.

- Material Versatility: Sintering can be used with a variety of materials (polymers, metals), allowing for both functional prototypes and end-use parts.

- Higher Strength: Parts produced via sintering, especially in metals, have higher strength compared to those produced with FDM or SLA.

Applications of Sintering in 3D Printing

Sintering plays a crucial role in the creation of both prototypes and final-use parts in various industries. Two primary methods, Selective Laser Sintering (SLS) and Direct Metal Laser Sintering (DMLS), are used across different sectors for unique applications.

Selective Laser Sintering (SLS)

SLS is a widely used 3D printing technique for producing functional prototypes, low-volume production parts, and end-use components. It primarily uses polymers like nylon, polycarbonate, and TPU (thermoplastic polyurethane). SLS is favored in industries like:

- Automotive: For creating lightweight parts such as brackets and custom tooling.

- Aerospace: For producing complex, lightweight components like ducts and brackets that reduce fuel consumption.

- Consumer Goods: For rapid prototyping and small-batch manufacturing of products like eyewear, footwear, and electronics.

Direct Metal Laser Sintering (DMLS)

DMLS, or Laser Powder Bed Fusion (LPBF), uses metal powders (e.g., titanium, stainless steel, cobalt-chrome) to create highly detailed and mechanically strong parts. This method is particularly advantageous in industries that require parts with exceptional strength and durability, such as:

- Aerospace: For producing lightweight, high-strength components like turbine blades and engine parts.

- Medical: For manufacturing custom implants, surgical instruments, and orthopedic devices.

- Dental: For producing customized dental implants and prosthetics.

Benefits and Limitations

Benefits of Sintering in 3D Printing

- Complex Geometries: Sintering is ideal for producing parts with intricate and complex shapes that would be difficult or impossible to achieve with traditional manufacturing methods.

- Minimal Support Structures: Unlike methods like FDM, sintering can produce parts with fewer or no support structures, reducing post-processing time.

- High Strength: Sintered parts are known for their high mechanical strength, making them suitable for functional prototypes and end-use parts in industries like aerospace, automotive, and medical.

- Material Flexibility: Sintering can be done with a wide range of materials, including various polymers and metals, giving manufacturers flexibility in choosing the right material for their application.

Limitations of Sintering

- Time-Consuming: Sintering processes, particularly DMLS, can be slower compared to other 3D printing methods like FDM, which can affect production timelines.

- Surface Finish: Sintered parts typically have a rough surface finish due to the nature of the powder bed process. Additional post-processing, such as polishing or coating, may be required to achieve a smoother surface.

- Cost: The use of high-quality powders (especially metal powders) can make sintering processes relatively expensive, especially for high-end materials like titanium or cobalt-chrome.

- Material Constraints: Some materials are better suited for sintering than others. For instance, sintering is not ideal for certain composites or materials that cannot be easily powderized or sintered.

Material Considerations

The choice of material in sintering is critical to achieving the desired properties for the final part. Different materials exhibit different characteristics that can influence the strength, flexibility, and suitability of the part for specific applications.

Polymer Powders

- Nylon: One of the most commonly used materials in SLS, nylon is known for its strength, flexibility, and abrasion resistance, making it ideal for functional parts and prototypes.

- Polycarbonate: Another popular choice, polycarbonate offers high-impact strength and is often used in applications where durability is critical.

- TPU: Thermoplastic polyurethane is used for parts requiring elasticity and flexibility, such as seals or flexible enclosures.

Metal Powders

- Titanium: Widely used in aerospace, medical, and automotive industries due to its strength, light weight, and corrosion resistance.

- Stainless Steel: Known for its durability and strength, it is commonly used in industrial applications like tooling and jigs.

- Cobalt-Chrome: Valued in the medical and dental industries for its biocompatibility and wear resistance, making it ideal for implants and prosthetics.

Material Properties

The mechanical properties of sintered parts, such as strength, hardness, and elasticity, are determined by the type of powder used and the parameters of the sintering process. Metal powders tend to produce parts with higher strength compared to polymer powders, making them suitable for critical applications like aerospace components or medical implants. Conversely, polymer sintering is more cost-effective and versatile for prototyping and low-volume production.

Industry Applications

Aerospace and Automotive

- Aerospace: Sintering is used to produce high-precision components like turbine blades, fuel injectors, and brackets that need to withstand extreme conditions. The ability to create lightweight and complex parts reduces overall weight, which is crucial for performance and fuel efficiency.

- Automotive: In the automotive industry, sintering enables the production of lightweight, high-performance parts that can enhance fuel efficiency and vehicle performance. Examples include engine parts, custom brackets, and exhaust components.

Medical and Dental

- Medical: Sintering enables the customization of implants, such as knee or hip replacements, that are tailored to fit individual patients. The high strength and biocompatibility of sintered metal parts make them suitable for implants, surgical instruments, and prosthetics.

- Dental: Custom dental crowns, bridges, and implants are often produced using sintering, enabling rapid production and improving the fit and comfort for patients.

Architectural Modeling

Sintering is also used in architecture to create highly detailed and accurate scale models. These models help architects visualize their designs and conduct site analysis, with sintering allowing for intricate features and geometries that traditional methods might struggle to achieve.

FAQs

- What materials can be used in the sintering process?

- Sintering can be done with various materials, including polymers (nylon, polycarbonate) and metals (stainless steel, titanium, cobalt-chrome). The choice depends on the application, such as strength, flexibility, or biocompatibility.

- How does sintering differ from other 3D printing techniques?

- Sintering involves heating powder to just below its melting point, causing particles to fuse together. Unlike methods like FDM, which extrude melted filament, sintering produces parts with higher mechanical strength and fine detail, suitable for complex geometries and functional prototypes.

- What are the main benefits of using sintering in 3D printing?

- The main benefits include the ability to create complex geometries, high-strength parts, and minimal need for support structures. It is ideal for producing both functional prototypes and end-use parts, especially in industries like aerospace, automotive, medical, and dental.