Introduction to 3D Printing in Canada

3D printing, or additive manufacturing, is transforming industries across the globe, and Canada is no exception. This cutting-edge technology is fundamentally reshaping the way products are designed, produced, and delivered. By enabling rapid prototyping, reducing material waste, and offering unprecedented design flexibility, 3D printing is enhancing manufacturing efficiency, fostering innovation, and paving the way for more sustainable business practices. This article explores how 3D printing is revolutionizing key sectors in Canada such as aerospace, automotive, healthcare, and consumer goods.

Overview of 3D Printing Technology

3D printing involves creating three-dimensional objects from a digital file by adding material layer by layer. This contrasts with traditional manufacturing methods, which typically subtract material to create the final product. There are several types of 3D printing technologies, including:

- Fused Deposition Modeling (FDM): Extrudes melted plastic filament through a nozzle to build objects layer by layer. Common for prototyping and low-cost production.

- Stereolithography (SLA): Uses a UV light to cure liquid resin into solid layers, providing high-precision models with smooth surfaces.

- Selective Laser Sintering (SLS): Utilizes a laser to fuse powdered material, enabling the production of complex, strong parts without the need for support structures.

- Digital Light Processing (DLP): Similar to SLA but uses a digital light projector to cure the resin, offering faster print times for high-precision applications.

These technologies enable the creation of highly intricate parts that would be difficult or impossible to produce using traditional manufacturing methods, opening up new possibilities in design, material selection, and production processes.

Historical Context of 3D Printing in Canada

Canada has been at the forefront of 3D printing innovation from its early days. The National Research Council of Canada (NRC) has played a key role in advancing additive manufacturing, supporting research and development across various fields, from materials science to engineering applications. Over the years, Canadian universities and private companies have invested heavily in this technology, helping position Canada as a global leader in 3D printing.

Startups and established companies in Canada are continually exploring new ways to harness 3D printing for both industrial applications and consumer products. The nation's strong innovation ecosystem, which includes funding programs, innovation hubs, and partnerships between industry and academia, has made Canada an attractive destination for 3D printing companies and researchers.

Industries Impacted by 3D Printing

Aerospace and Defense

The aerospace and defense industries in Canada are benefitting significantly from 3D printing. Companies like Magellan Aerospace and MDA (MacDonald, Dettwiler and Associates) are using additive manufacturing to produce lightweight, complex parts for aircraft and satellites. The ability to manufacture intricate geometries that reduce the weight of components without sacrificing strength is crucial for improving fuel efficiency and overall performance.

In addition to rapid prototyping (enabling engineers to quickly test new designs), 3D printing allows for on-demand production of replacement parts, which is essential for aerospace maintenance. This capability significantly cuts down on lead times and inventory costs, contributing to more efficient operations.

Automotive Manufacturing

In the automotive industry, Canadian companies are embracing 3D printing for both rapid prototyping and the production of customized parts. Automakers can quickly iterate designs, reducing the time and cost involved in creating new models or parts. 3D printing also enables the creation of lightweight components that can enhance vehicle fuel efficiency and performance.

For example, Magna International, one of the world’s largest automotive suppliers, is exploring how 3D printing can optimize the production of complex parts and tools. Additionally, 3D printing can help car manufacturers offer customization options for consumers, from custom interiors to unique exterior parts.

Medical and Healthcare

In the medical field, 3D printing has been transformative in creating custom prosthetics, implants, and surgical guides. Canadian companies like 3DHEALS and Stratasys have helped revolutionize patient care by enabling the creation of personalized medical devices that are tailored to the specific needs of each patient. These custom products improve patient comfort, enhance outcomes, and lower costs by eliminating the need for traditional, mass-produced devices.

One of the most exciting applications is in bioprinting, where Canadian researchers are working to print tissues and organs for use in regenerative medicine and organ transplantation. While still in its early stages, this field holds the potential to change the future of healthcare, providing solutions to organ shortages and improving patient care through customized medical solutions.

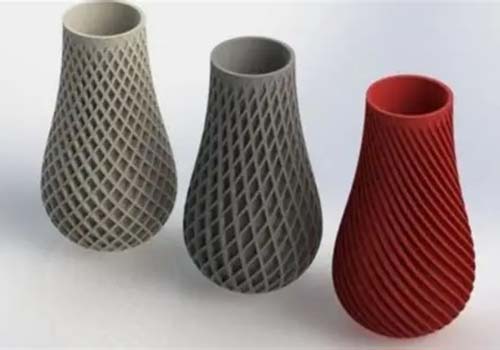

Consumer Goods and Electronics

The consumer goods and electronics sectors are also benefiting from 3D printing’s flexibility. Manufacturers can produce customized products quickly, catering to consumer demand for personalized and bespoke items. Companies in Canada, such as Sculpteo, are enabling businesses to offer customers unique, customized products—from fashion accessories to home goods.

Additionally, rapid prototyping is helping companies innovate faster, allowing them to bring new products to market quickly. This is particularly valuable in the electronics industry, where time-to-market can make a significant difference in competitiveness. 3D printing also enables more efficient production of spare parts for consumer electronics, extending product lifespans and reducing the need for full replacements.

Benefits of 3D Printing in Canada

Economic Growth and Job Creation

3D printing has the potential to drive substantial economic growth and job creation in Canada. As more industries adopt this technology, the demand for skilled workers in design, engineering, manufacturing, and materials science is rising. This is particularly important for small businesses and startups, which now have access to advanced manufacturing capabilities without needing massive capital investment.

Moreover, 3D printing can contribute to the localization of manufacturing in Canada, reducing reliance on offshore production and supporting local supply chains. This is especially crucial in industries like aerospace and automotive, where the ability to produce custom or low-volume parts locally can lead to significant cost savings and improved operational efficiency.

Environmental Sustainability

3D printing offers several environmental benefits, particularly in terms of material efficiency and reduced waste. Traditional manufacturing processes often involve subtractive techniques (like milling or casting), which generate significant material waste. In contrast, 3D printing only uses the material necessary to build an object, minimizing waste and maximizing material usage.

Additionally, 3D printing supports local production, which can reduce the environmental impact of transportation. By printing parts on demand, companies can also avoid overproduction, reducing excess inventory and energy consumption associated with large-scale manufacturing.

Innovation and Competitiveness

3D printing fosters innovation by enabling companies to quickly test new designs, materials, and manufacturing methods. This capability is particularly valuable for Canadian businesses looking to stay competitive in a global market. The ability to create unique, complex parts allows companies to differentiate their products and add value in ways that traditional manufacturing methods cannot.

For instance, businesses in design-intensive sectors, such as fashion and architecture, can use 3D printing to experiment with new forms and structures, leading to creative breakthroughs and more personalized products. In a country like Canada, where innovation is key to staying ahead in a competitive global market, 3D printing is a powerful tool for driving growth.

FAQs

What are the main advantages of 3D printing for small businesses in Canada?

Small businesses in Canada can benefit from 3D printing in several ways:

- Cost Efficiency: Reduced material waste and lower production costs compared to traditional manufacturing methods.

- Rapid Prototyping: Quickly iterate on designs and bring products to market faster.

- Customization: Offer bespoke products and services tailored to individual customer needs.

- Local Production: Minimize shipping costs and lead times by producing locally.

- Innovation: Experiment with new materials and designs without significant upfront investment.

How does 3D printing contribute to sustainability?

3D printing contributes to sustainability through several mechanisms:

- Material Efficiency: Additive manufacturing minimizes waste by building objects layer by layer.

- Energy Consumption: Often requires less energy than traditional subtractive manufacturing processes.

- Local Production: Reduces the carbon footprint associated with long-distance shipping.

- Reusable Materials: Many 3D printing processes use recyclable materials, promoting a circular economy.

- On-Demand Production: Helps reduce overproduction and excess inventory, leading to more efficient resource use.

What skills are essential for professionals working in the 3D printing industry?

Professionals in the 3D printing industry should possess a combination of technical and soft skills:

- Technical Proficiency: Expertise in CAD software for designing 3D models.

- Material Science: Understanding of different materials used in 3D printing and their properties.

- Operational Skills: Knowledge of operating and maintaining 3D printers.

- Problem-Solving: Ability to troubleshoot issues related to print quality and machine performance.

- Innovation: Creativity in designing and developing new applications for 3D printing.

- Collaboration: Strong communication skills for working with cross-functional teams and clients.

Conclusion

In Canada, 3D printing is revolutionizing industries by fostering innovation, improving efficiency, and supporting sustainability. From aerospace and automotive to healthcare and consumer goods, this technology is changing how companies design, produce, and deliver products. The potential for economic growth and job creation, coupled with the environmental benefits of reduced waste and energy use, positions 3D printing as a powerful driver of the future. As Canadian businesses continue to embrace this transformative technology, they are poised to lead the way in manufacturing excellence, innovation, and sustainability.