Introduction

In the rapidly evolving landscape of modern manufacturing, 3D printing custom parts have emerged as a game - changing solution, revolutionizing the way products are designed, prototyped, and produced. This technology allows for the creation of highly customized, complex, and functional components, catering to a wide range of industries such as aerospace, automotive, healthcare, and consumer goods.

The importance of 3D printing custom parts lies in its ability to overcome many limitations of traditional manufacturing methods. For example, traditional manufacturing often requires expensive molds and tooling for custom parts, which can be time - consuming and cost - prohibitive, especially for small - batch production. In contrast, 3D printing enables on - demand production, reducing lead times and inventory costs. It also offers unprecedented design freedom, allowing engineers to create intricate geometries that were previously impossible or extremely difficult to manufacture.

Moreover, in industries like healthcare, 3D - printed custom parts such as prosthetics can be tailored precisely to an individual's anatomy, providing a better fit and functionality. In aerospace, lightweight and high - strength 3D - printed components can enhance fuel efficiency and overall performance of aircraft. Given these remarkable advantages, it's essential to understand the ins and outs of 3D printing custom parts. In the following sections, we will explore various aspects, including the types of 3D printing technologies suitable for custom parts, materials used, cost - effectiveness, and how to choose the right service provider.

How Does 3D Printing for Custom Parts Work?

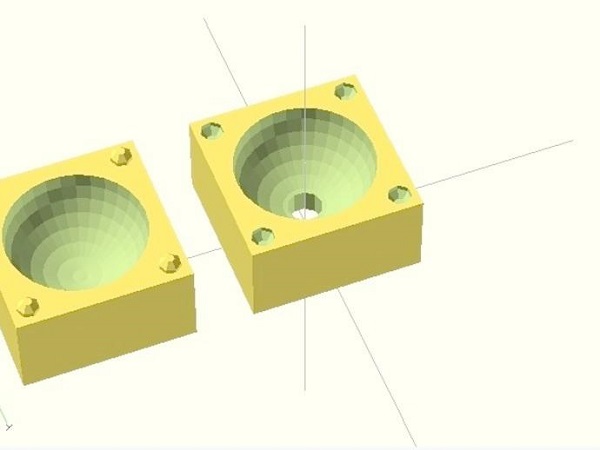

At its core, 3D printing for custom parts is an additive manufacturing process. It starts with a digital 3D model, typically created using Computer - Aided Design (CAD) software. This model serves as the blueprint for the final custom part.

Think of it like building a loaf of bread, layer by layer. Instead of using flour, water, and yeast, 3D printing uses various materials such as plastics, metals, ceramics, or even composites. Once the CAD model is ready, it is sliced into thin cross - sectional layers by specialized software. Each layer represents a horizontal slice of the final 3D object, with the thickness usually ranging from as thin as 0.01 mm to a few millimeters, depending on the printer and the desired quality.

The 3D printer then reads the sliced data and starts depositing or fusing materials layer by layer according to the design. For example, in Fused Deposition Modeling (FDM), which is one of the most common 3D - printing technologies, a spool of thermoplastic filament (such as PLA or ABS) is fed into an extruder. The extruder heats the filament until it melts and then precisely deposits the molten plastic in the shape defined by the first layer of the sliced model onto a build platform. As the layer is completed, the build platform may lower slightly, and the next layer is printed on top of the previous one. This process continues until the entire 3D part is built, with each layer bonding to the one beneath it.

In other technologies like Stereolithography (SLA), a vat of photosensitive resin is used. An ultraviolet (UV) laser traces the shape of each layer onto the surface of the resin, curing it and solidifying it into the desired form. With Selective Laser Sintering (SLS), a laser sinters powdered materials (such as nylon or metal powders) together, layer by layer, to create the part. After the printing process is complete, the 3D - printed custom part may require some post - processing steps. These can include removing support structures (if they were used during printing to hold up overhanging parts), sanding, polishing, or heat - treating to improve the part's surface finish, mechanical properties, or dimensional accuracy.

Materials Used in 3D Printing Custom Parts

Plastics

Plastics are among the most commonly used materials in 3D printing for custom parts. Polylactic Acid (PLA) is a popular choice, especially for beginners and those focused on environmental - friendliness. Derived from renewable resources like corn starch or sugarcane, PLA is biodegradable. It has a relatively low melting point, making it easy to print with, and it rarely warps during the printing process. This makes PLA ideal for creating prototypes, educational models, and decorative items. For example, in a classroom setting, students can use PLA to 3D - print small sculptures or simple mechanical models due to its ease of use and non - toxic nature during printing.

Acrylonitrile Butadiene Styrene (ABS), on the other hand, offers higher strength and heat resistance compared to PLA. It has good impact resistance and is often used in applications where durability is crucial. ABS is commonly employed in the automotive industry for prototyping parts such as dashboards, bumpers, or interior components. Manufacturers can quickly produce functional prototypes using ABS to test the fit and functionality of these parts before mass production. However, ABS does release some fumes during printing, so proper ventilation is required.

Metals

The use of metals in 3D printing for custom parts has opened up new possibilities in industries like aerospace, automotive, and healthcare. Titanium alloys are highly valued for their exceptional strength - to - weight ratio, corrosion resistance, and biocompatibility. In aerospace, 3D - printed titanium alloy components are used in aircraft engines and structural parts. These parts can be designed with complex internal geometries to optimize weight and performance. For instance, a 3D - printed titanium alloy turbine blade can be made lighter while maintaining its strength, leading to improved fuel efficiency of the aircraft engine.

Aluminum alloys are also widely used. They are lightweight, have good thermal conductivity, and are relatively easy to process in 3D printing. In the automotive industry, aluminum alloy 3D - printed parts such as engine blocks and suspension components can help reduce the overall weight of the vehicle, enhancing fuel economy and performance. Metal 3D printing techniques like Selective Laser Melting (SLM) can precisely fuse metal powders layer by layer to create these high - quality custom parts.

Other Materials

Ceramics are used in 3D printing for applications that require high - temperature resistance, hardness, and chemical stability. In the aerospace industry, 3D - printed ceramic parts can be used in heat - shield components due to their ability to withstand extreme temperatures. In the electronics industry, ceramic substrates printed through 3D technology can provide excellent electrical insulation and thermal management. For example, some high - end electronic devices use 3D - printed ceramic parts to ensure stable performance under high - temperature and high - voltage conditions.

Composites combine the properties of two or more materials to achieve unique characteristics. Carbon - fiber - reinforced composites, for example, offer high strength and stiffness while being lightweight. These are often used in the sports equipment industry to make items like bicycle frames, tennis rackets, and golf club shafts. The 3D printing of composites allows for the creation of custom - designed structures that can be optimized for specific performance requirements.

Yigu Technology's View

As a non - standard plastic metal products custom supplier, Yigu Technology firmly believes that 3D printing custom parts hold a promising future. The versatility of 3D printing aligns perfectly with our mission to provide unique solutions for our clients.

We take pride in our extensive material library, which includes a wide range of plastics and metals suitable for 3D printing. This allows us to meet the diverse needs of our customers, whether they require parts with high strength, heat resistance, or biocompatibility. Our expertise in various 3D - printing processes, such as FDM, SLA, and SLM, ensures that we can select the most appropriate technology for each project, guaranteeing high - quality results.

At Yigu Technology, we understand that every client's project is unique. Therefore, we offer personalized services, working closely with our clients from the initial design concept to the final production of 3D - printed custom parts. We are committed to leveraging 3D printing technology to deliver innovative, cost - effective, and high - performance solutions for all your non - standard plastic and metal product needs.

FAQ

What types of designs are suitable for 3D printing custom parts?

Complex and intricate designs with unique geometries, such as parts with internal channels, lattice structures, or organic - shaped forms, are highly suitable for 3D printing. For example, a heat - sink design with complex internal fins to enhance heat dissipation can be easily 3D - printed. Also, highly personalized designs like custom - fit prosthetics that are tailored to an individual's body measurements are ideal candidates. Designs with undercuts or overhangs that would be difficult to manufacture using traditional methods can be printed without much hassle with proper support structures in 3D printing.

How accurate are 3D printed custom parts?

The accuracy of 3D printed custom parts depends on several factors, including the type of 3D printer and the materials used. Generally, modern 3D printers can achieve high levels of accuracy. For instance, some industrial - grade FDM printers can have an accuracy of ±0.2 mm, while SLA and DLP printers, which use light - curing processes, can offer even higher precision, often around ±0.1 mm or in some high - end cases, as low as ±0.01 mm for professional resin 3D printers. Metal 3D printers, like those using SLM technology, typically have an accuracy of about ±0.1 mm. In most cases, these levels of accuracy are sufficient to meet the requirements of a wide range of applications, from prototyping to small - batch production of functional parts.

Can I use 3D printed custom parts for mass production?

3D printed custom parts can be used for small - batch production with great advantages. They offer flexibility in design changes, reduced tooling costs, and on - demand production capabilities. For example, luxury car manufacturers might use 3D printing to produce small numbers of custom - designed spare parts. However, for large - scale mass production, traditional manufacturing methods are often more suitable in terms of speed and cost - effectiveness. The relatively slow printing speed of 3D printers can be a bottleneck for high - volume production. But in some cases, a combination of 3D printing and traditional manufacturing can be a great solution. For instance, 3D printing can be used to create molds or prototypes, which are then used in traditional manufacturing processes like injection molding for mass production.