Introduction

In the ever - evolving landscape of manufacturing and engineering, 3D printing has emerged as a revolutionary technology, and its application in the creation of fuel tanks is no exception. A 3D printed fuel tank, as the name implies, is a fuel - storing container fabricated through additive manufacturing processes. This innovative approach to fuel tank production has opened up a plethora of possibilities that were previously unthinkable with traditional manufacturing methods.

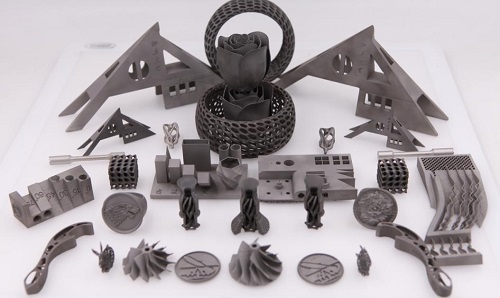

The traditional manufacturing of fuel tanks often involves processes like blow - molding, stamping, and welding of metal or plastic sheets. These methods have limitations in terms of design complexity, material waste, and production time. In contrast, 3D printing allows for the creation of fuel tanks with intricate geometries, customized to fit specific requirements. For example, in the aerospace industry, where every gram of weight reduction matters, 3D printed fuel tanks can be designed to have a lightweight yet strong lattice - like internal structure that traditional manufacturing simply cannot achieve.

Fuel storage is a crucial aspect in various industries, from automotive and aviation to marine and energy. The potential of 3D printed fuel tanks in this area is immense. They can be made to have better fuel - containment properties, reduced risk of leakage due to seamless construction in many cases, and enhanced resistance to corrosion depending on the materials used. As we delve deeper into this article, we will explore the advantages, challenges, materials, and applications of 3D printed fuel tanks in detail, and how they are reshaping the fuel storage paradigm.

Applications of 3D Printed Fuel Tanks

Aerospace Industry

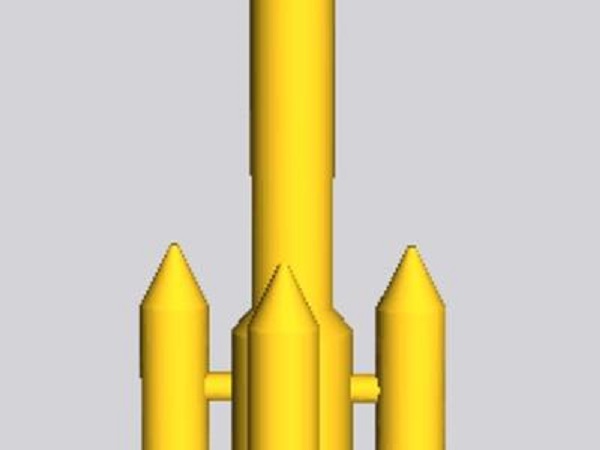

In the aerospace industry, 3D printed fuel tanks have found significant applications. For example, some unmanned aerial vehicles (UAVs) have started to utilize 3D printed fuel tanks. A case in point is the Aurora Flight Sciences' jet - powered UAV. The 3D printed fuel tank in this UAV combines multiple components such as internal and external printed pipes, brackets connecting fuel filters and pumps, and small clips for fuel 管路. This design not only enables precise control of the center of gravity, which is crucial for the flight performance of the UAV, but also reduces the number of parts and potential leakage points.

For larger aircraft, 3D printed fuel tanks can contribute to significant weight reduction. Since every kilogram of weight reduction in an aircraft can lead to a reduction in fuel consumption during flight, 3D printed fuel tanks with their optimized internal structures (such as lattice structures) can achieve this goal. According to research, a 10% reduction in the weight of an aircraft's fuel - related components can lead to approximately a 5 - 8% decrease in overall fuel consumption during long - haul flights. This not only saves fuel costs but also reduces the environmental impact of aviation.

Automotive Industry

The automotive industry also holds great potential for the application of 3D printed fuel tanks. With the increasing demand for vehicle customization and the pursuit of better fuel efficiency, 3D printed fuel tanks can play a vital role. General Motors has been exploring the use of 3D printing in automotive parts production. Their 3D printed aluminum fuel tanks for the Chevrolet Corvette C8.R race car have shown remarkable results. The 3D printed fuel tank integrates eight separate components, eliminating 14 welds and reducing the weight by 32%.

Moreover, 3D printed fuel tanks can be customized to fit different vehicle models and driving requirements. For electric vehicles, although the energy source is electricity, there are still some auxiliary systems that may require fuel - like substances for operation, and 3D printed fuel tanks can be designed to meet the space - saving and functional requirements of these systems. According to a study by a leading automotive research institute, by 2025, the market penetration rate of 3D printed fuel - related components in the automotive industry is expected to reach 15 - 20%, driven by the continuous improvement of 3D printing technology and the increasing demand for lightweight and customized automotive components.

Yigu Technology's View

As a non - standard plastic metal products custom Supplier, Yigu Technology is highly optimistic about the prospects of 3D printed fuel tanks. The design flexibility of 3D printing technology allows for the creation of fuel tanks with complex and customized shapes, which can better meet the diverse needs of different industries. Moreover, 3D printing can potentially reduce production costs in the long run by minimizing material waste and shortening the production cycle.

Yigu Technology believes that by collaborating with various research institutions and manufacturers, continuous innovation in materials and manufacturing processes for 3D printed fuel tanks can be achieved. We are eager to contribute our expertise in plastic and metal materials, as well as our experience in custom manufacturing, to promote the wider application of 3D printed fuel tanks.

FAQs

1. Is 3D printed fuel tank safe?

3D printed fuel tanks are considered safe. They undergo rigorous safety tests, and both the materials used and the structural design comply with strict safety standards. For example, in the automotive industry, 3D printed fuel tanks used in some racing cars have passed high - speed impact and pressure - resistance tests. In actual applications, many small - scale aircraft with 3D printed fuel tanks have been operating safely for years, demonstrating the reliability of 3D printed fuel tanks in real - world scenarios.

2. How long does it take to 3D print a fuel tank?

The printing time of a 3D printed fuel tank is influenced by multiple factors, such as the size of the fuel tank, the complexity of the design, and the type of 3D printer used. Generally, for a small - scale fuel tank with a simple design, it may take about 10 - 20 hours to print. Larger and more complex fuel tanks, like those used in some industrial machinery or large - sized aircraft, could take several days to print, perhaps 3 - 7 days. However, with the continuous optimization of printing parameters and the improvement of 3D printer performance, the printing time can be significantly shortened.

3. Can 3D printed fuel tanks be customized for different vehicles?

Yes, one of the greatest advantages of 3D printed fuel tanks is their high degree of customization. For example, 3D printed fuel tanks have been customized for electric vehicles, hybrid vehicles, and various types of off - road vehicles. The customization process usually starts with a detailed design phase, where engineers use CAD software to design the fuel tank according to the vehicle's specific space, fuel - carrying requirements, and performance needs. Then, the 3D printer fabricates the fuel tank based on the digital model. In the marine industry, 3D printed fuel tanks have also been customized for different sizes and types of boats to ensure a perfect fit and optimal performance.

Conclusion

In conclusion, 3D printed fuel tanks offer a host of advantages that have the potential to revolutionize the fuel storage industry. Their design flexibility allows for the creation of fuel tanks with complex geometries, optimized for specific applications in industries such as aerospace and automotive. The ability to integrate multiple components into a single 3D printed unit reduces the number of parts, potential leakage points, and overall weight, leading to improved performance and fuel efficiency.

However, as with any emerging technology, 3D printed fuel tanks also face challenges. Technical issues such as printing accuracy and material compatibility need to be continuously addressed through research and development. The ongoing efforts in improving 3D printing technologies and developing new materials hold great promise for overcoming these obstacles.

Despite the challenges, the applications of 3D printed fuel tanks in the aerospace and automotive industries have already shown their viability and potential for growth. As technology advances and the challenges are overcome, we can expect to see an increasing adoption of 3D printed fuel tanks in more industries and applications.