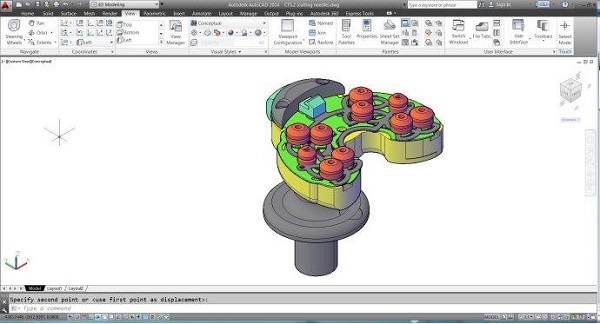

Understanding Electroplating 3D Printed Parts

Electroplating 3D printed parts is a process that combines the precision and flexibility of 3D printing with the enhanced properties offered by electroplating. 3D printing, also known as additive manufacturing, creates three - dimensional objects from a digital file by depositing materials layer by layer. After the 3D printing process is complete, electroplating can be applied.

Electroplating involves using an electric current to deposit a thin layer of metal onto a substrate. In the case of 3D printed parts, the substrate is the 3D printed object. This metal layer can be of various metals such as nickel, chrome, copper, etc. Each metal offers different properties:

- Nickel plating: It provides excellent corrosion resistance. For example, in an outdoor - exposed 3D printed part used in a machinery component, nickel - plated 3D printed parts can last up to 3 - 5 times longer than non - plated parts in a humid environment, according to industry tests.

- Chrome plating: Enhances the hardness and wear resistance of the 3D printed part. In automotive interior 3D printed decorative components, chrome - plated parts can withstand 50% more friction during normal use compared to unplated parts.

- Copper plating: Copper is a good conductor of electricity. When 3D printed parts are used in electrical components, copper - plated 3D printed parts can reduce electrical resistance by up to 40%, improving the overall efficiency of the electrical system.

The combination of 3D printing and electroplating unlocks new possibilities. 3D printing allows for the creation of complex geometries that are difficult or impossible to achieve with traditional manufacturing methods. Electroplating then improves the performance of these 3D printed parts, making them suitable for a wider range of applications, from aerospace components to consumer electronics. For instance, in the aerospace industry, 3D printed parts with electroplated surfaces can meet the high - strength and corrosion - resistance requirements while reducing the weight of the components due to the design freedom of 3D printing.

The Process of Electroplating 3D Printed Parts

Surface Preparation

Before electroplating, the surface of the 3D printed part must be properly prepared. This is a crucial step as it directly affects the adhesion of the electroplated layer.

- Cleaning: First, the part is thoroughly cleaned to remove any contaminants such as dust, grease, or residual printing materials. Solvent cleaning is a common method. For example, parts made from acrylonitrile butadiene styrene (ABS) can be cleaned with isopropyl alcohol. This helps to ensure that the subsequent steps are carried out on a clean surface.

- Roughing: After cleaning, the surface is often roughened. For plastic - based 3D printed parts like ABS, chemical etching with a solution of chromic acid and sulfuric acid can be used to create a rough surface texture. This roughness increases the surface area, enhancing the adhesion of the electroplated layer. Different materials have different requirements for surface preparation. For instance, 3D printed parts made from polycarbonate (PC) require a different etching solution compared to ABS due to the differences in their chemical structures. PC may need a more mild etching agent to avoid over - etching and damaging the part.

Conductive Layer Deposition

Since most 3D printed materials are non - conductive, a conductive layer needs to be deposited on the part's surface before electroplating.

- Electroless Plating: This is a widely used method. For example, electroless nickel plating can be applied to 3D printed parts. In this process, a chemical reaction occurs in a bath containing nickel salts, reducing agents, and other additives. The nickel ions are reduced and deposited onto the part's surface, forming a conductive layer. The advantage of electroless plating is that it can provide a uniform coating even on complex 3D geometries. However, it can be time - consuming, and the process requires careful control of the bath chemistry.

- Sputtering: Sputtering is another option. It involves bombarding a target material (such as copper or silver) with high - energy particles in a vacuum chamber. The atoms from the target are then deposited onto the 3D printed part. Sputtering can produce a very thin and high - quality conductive layer quickly. But it requires expensive equipment and is less suitable for large - scale production due to its relatively low deposition rate.

Electroplating Bath Setup

The choice of electroplating bath is crucial for achieving the desired properties of the electroplated layer.

- Common Electroplating Bath Formulations:

- Nickel Plating Bath: A typical nickel plating bath contains nickel sulfate (\(NiSO_4\)), nickel chloride (\(NiCl_2\)), and boric acid (\(H_3BO_3\)). Nickel sulfate provides the nickel ions for deposition, nickel chloride helps with anode dissolution and improves the conductivity of the bath, and boric acid acts as a buffer to maintain the pH of the bath. This bath is suitable for applications where corrosion resistance and hardness are required, such as in automotive and aerospace components.

- Copper Plating Bath: A common copper plating bath consists of copper sulfate (\(CuSO_4\)) and sulfuric acid (\(H_2SO_4\)). Copper sulfate supplies the copper ions, and sulfuric acid increases the conductivity of the bath and helps in the deposition process. Copper plating is often used when good electrical conductivity is needed, for example, in 3D printed parts for electrical connectors.

The Electroplating Process Itself

Once the surface is prepared, the conductive layer is deposited, and the electroplating bath is set up, the actual electroplating process can begin.

- Process Steps: The 3D printed part is immersed in the electroplating bath and connected to the cathode of an electrical circuit, while the anode is made of the metal to be deposited (or a soluble anode in some cases). When an electric current is applied, metal ions in the bath are attracted to the negatively charged cathode (the 3D printed part) and are deposited onto its surface.

- Parameter Control: Key parameters such as current density, temperature, and plating time need to be carefully controlled. For example, when copper plating a 3D printed part, if the current density is too high, the deposited copper layer may be rough and have poor adhesion. A proper current density range for copper plating is usually between 1 - 3 A/dm². The temperature of the bath also affects the plating quality. For a standard copper plating bath, the optimal temperature is around 20 - 30°C. Plating time depends on the desired thickness of the deposited layer. Generally, for a 10 - 20 µm thick copper layer, the plating time may range from 30 minutes to 2 hours.

Yigu Technology's View

As a non - standard plastic metal products custom Supplier, Yigu Technology has rich experience in electroplating 3D printed parts. Our advanced technology allows us to handle various 3D printed materials, ensuring high - quality electroplating results.

We understand the importance of each step in the electroplating process, from surface preparation to the final electroplating. Our strict quality control system ensures that every electroplated 3D printed part meets or exceeds industry standards. We offer customized electroplating solutions according to our clients' specific requirements, whether it's for enhancing corrosion resistance, improving electrical conductivity, or achieving a certain aesthetic appearance. With Yigu Technology, you can expect fast turnaround times, cost - effective services, and excellent after - sales support.

FAQ

Q1: What materials are suitable for electroplating 3D printed parts?

Materials such as acrylonitrile butadiene styrene (ABS), polycarbonate (PC), and some types of resins are suitable for electroplating 3D printed parts. ABS is a popular choice because it can be easily cleaned and etched, which helps in achieving good adhesion of the electroplated layer. PC also has good compatibility with the electroplating process, although it requires a different etching solution compared to ABS due to its chemical structure. Resins, especially those designed for 3D printing with electroplating in mind, can also be effectively electroplated. These materials' ability to bond well with the conductive layer and the electroplated metal makes them suitable candidates for the electroplating process.

Q2: How much does the electroplating process for 3D printed parts cost?

The cost of electroplating 3D printed parts depends on several factors. The surface area of the part is a major factor; larger surface areas will require more materials and longer processing times, thus increasing the cost. The type of metal used for electroplating also matters. For example, gold plating is more expensive than nickel or copper plating due to the higher cost of gold. Additionally, the complexity of the surface preparation and the required quality of the electroplated layer can impact the cost. Generally, for small - scale, simple 3D printed parts with a common metal like nickel plating, the cost can range from a few dollars to tens of dollars per part. However, for large - scale production or parts that require precious metal plating, the cost can be significantly higher.

Q3: Can electroplating improve the mechanical properties of 3D printed parts?

Yes, electroplating can improve the mechanical properties of 3D printed parts. For instance, nickel - plated 3D printed parts show enhanced corrosion resistance, which is a mechanical - property - related improvement as it protects the part from degradation in harsh environments. Chrome plating can increase the hardness and wear resistance of the 3D printed part. In applications where the part is subject to friction or abrasion, such as in moving mechanical components, the electroplated chrome layer can withstand the forces better than the original 3D printed material, thus improving the overall mechanical performance. Copper plating can enhance the electrical conductivity of 3D printed parts used in electrical applications, which is also an important mechanical - property - related improvement in the context of electrical - mechanical systems.