Introduction

In the dynamic world of manufacturing, Plastic Injection Moulding Products Manufacturers play a pivotal role. Their ability to deliver precision-engineered plastic components is the cornerstone of success for numerous industries. Precision in plastic injection moulding is not just a desirable trait; it's an absolute necessity, especially in sectors like electronics and automotive.

The Process of Plastic Injection Moulding

Step - by - Step Breakdown

- Plastic Granule Heating: The process begins with the selection of appropriate plastic granules. These granules are poured into the hopper of the injection - molding machine. The machine then heats the granules. For example, in a standard injection - molding machine, the heating barrel is equipped with multiple heating zones. Each zone has a specific temperature setting. The rear zone is usually set at a relatively lower temperature, around 150 - 180°C for common plastics like polyethylene (PE), to gradually start the softening process. As the granules move forward towards the front of the barrel, the temperature increases. The front zone may be set at 200 - 250°C for PE, where the granules are fully melted into a viscous liquid state, ready for injection.

- Injection into the Mold: Once the plastic is in a molten state, the injection unit of the machine comes into action. A reciprocating screw inside the barrel rotates, pushing the molten plastic forward. The injection pressure can range from 50 - 200 MPa depending on the complexity of the mold and the type of plastic. For a simple - shaped part made of polypropylene (PP), a relatively lower injection pressure of around 80 - 100 MPa might be sufficient. The molten plastic is forced through a nozzle and into the mold cavity. The mold cavity is designed according to the desired shape of the final plastic product.

- Cooling: After the mold cavity is filled with the molten plastic, the cooling process starts. This is a crucial step as it determines the final shape and dimensional stability of the product. Cooling channels are built into the mold. These channels are usually filled with a coolant, such as water or a specialized heat - transfer fluid. The temperature of the coolant is carefully controlled. For example, for a small - sized plastic part, the coolant temperature might be maintained at around 20 - 30°C. As the hot plastic comes in contact with the cooler mold walls, heat is transferred from the plastic to the coolant. The cooling time varies based on the thickness and size of the part. A thin - walled part might cool in as little as 5 - 10 seconds, while a thick - walled component could take 30 seconds to several minutes to cool sufficiently.

- Demolding: Once the plastic part has cooled and solidified to a point where it can maintain its shape, the mold is opened, and the part is ejected. Ejection is typically achieved using ejector pins, which are small rods that push the part out of the mold cavity. The design of the ejector pins is crucial. They need to be placed in areas where they can provide sufficient force to eject the part without causing damage. For a complex - shaped part with undercuts, additional mechanisms like side - action cams or lifters may be required to facilitate the demolding process.

Key Factors Affecting Precision

| Factors | Impact on Precision (High, Medium, Low) | Explanation |

| Mold Design | High | The precision of the mold itself is fundamental. A well - designed mold with tight tolerances can produce parts with high accuracy. For example, if the mold cavity has a manufacturing tolerance of ±0.01 mm, it can significantly influence the final product's dimensional accuracy. The complexity of the mold design, such as the presence of intricate details and multiple cavities, also affects precision. Multi - cavity molds need to be carefully balanced to ensure uniform filling and cooling of each cavity. |

| Injection Pressure | High | Injection pressure affects how the molten plastic fills the mold cavity. If the pressure is too low, the plastic may not fully fill the cavity, leading to incomplete parts or inconsistent thickness. On the other hand, excessive pressure can cause the plastic to over - pack the cavity, resulting in dimensional changes, such as increased wall thickness or flash (excess plastic around the edges). A study by [Manufacturing Research Group] found that a 10% change in injection pressure can lead to a 0.5 - 1.5% change in the dimensional accuracy of the molded part. |

| Temperature Control | High | Temperature plays a vital role in both the plastic's viscosity and the cooling process. During the heating stage, inconsistent barrel temperatures can lead to non - uniform melting of the plastic, affecting its flow characteristics. In the cooling stage, uneven cooling due to improper temperature control in the mold can cause warping and dimensional inaccuracies. For instance, a temperature difference of 5°C between different parts of the mold can result in a part with a warpage of up to 0.2 - 0.5 mm in a medium - sized plastic component. |

| Cooling Time | Medium | If the cooling time is too short, the plastic may not have fully solidified, and the part can deform during demolding. However, an overly long cooling time is not only unproductive but can also lead to stress build - up in the part. A proper balance in cooling time, usually determined through trial - and - error or advanced simulation software, is necessary to ensure the part has the right mechanical properties and dimensional stability. |

| Plastic Material Properties | High | Different plastics have different shrinkage rates. For example, crystalline plastics like polyethylene terephthalate (PET) have a relatively high shrinkage rate compared to amorphous plastics like acrylonitrile - butadiene - styrene (ABS). The moisture content and the presence of additives in the plastic can also affect its behavior during molding, thus influencing the precision of the final product. |

Tips for Choosing the Right Plastic Injection Moulding Products Manufacturer

Understanding Your Requirements

Before starting the search for a Plastic Injection Moulding Products Manufacturer, it's crucial to have a clear understanding of your requirements. If you're in the medical device industry, for example, your plastic components will need to meet strict regulatory standards. The precision requirements for medical parts are often extremely high, with tolerances as low as ±0.001 - 0.005 mm in some cases. You'll also need to consider the volume of production. If you're planning to launch a new consumer product and expect high - volume sales, you'll need a manufacturer capable of large - scale production. For instance, if you anticipate selling 100,000 units of a plastic - cased electronic device per month, the manufacturer should have the capacity to meet this demand without sacrificing quality.

Material selection is another key aspect. Different plastics have different properties. Polycarbonate, for example, is known for its high impact resistance and heat resistance, making it suitable for applications like automotive headlight lenses. On the other hand, acrylonitrile - butadiene - styrene (ABS) is a popular choice for general - purpose applications due to its good mechanical properties, ease of processing, and relatively low cost. Understanding the specific requirements of your product will help you narrow down your choices when evaluating manufacturers.

Evaluating Manufacturer Capabilities

- Factory Visit: One of the best ways to assess a manufacturer's capabilities is to visit their factory. During the visit, you can observe the production process firsthand. Check the cleanliness and organization of the factory floor. A well - maintained and organized factory is often an indication of a company that values quality and efficiency. You can also see the condition of their injection - molding machines. Modern, well - maintained machines are more likely to produce high - quality parts consistently. For example, a factory equipped with the latest generation of Engel or Arburg injection - molding machines, which are known for their precision and reliability, is a positive sign.

- Equipment Inspection: In addition to the injection - molding machines, look at other equipment such as mold - making machinery and quality control equipment. A manufacturer with in - house mold - making capabilities can offer more flexibility and potentially faster turnaround times. High - precision CNC (Computer Numerical Control) machines for mold - making can ensure that the molds are made to exact specifications. Regarding quality control, the presence of equipment like coordinate measuring machines (CMMs) is crucial. CMMs can accurately measure the dimensions of the molded parts, ensuring that they meet the required tolerances. For example, a CMM with an accuracy of ±0.001 mm can detect even the slightest dimensional variations in a plastic part.

- Quality Control System: Inquire about the manufacturer's quality control system. A good manufacturer will have a comprehensive quality control plan in place, which includes inspection at various stages of the production process. They should conduct raw material inspections to ensure that the plastic granules meet the required specifications. During production, in - process inspections should be carried out to detect and correct any issues early. For example, random sampling of parts during the injection - molding process to check for defects such as flash, warping, or poor surface finish. Finally, a final inspection of the finished products should be done before they are shipped. Look for manufacturers that are ISO 9001 certified, as this indicates that they have a well - established quality management system.

Yigu Technology's Perspective

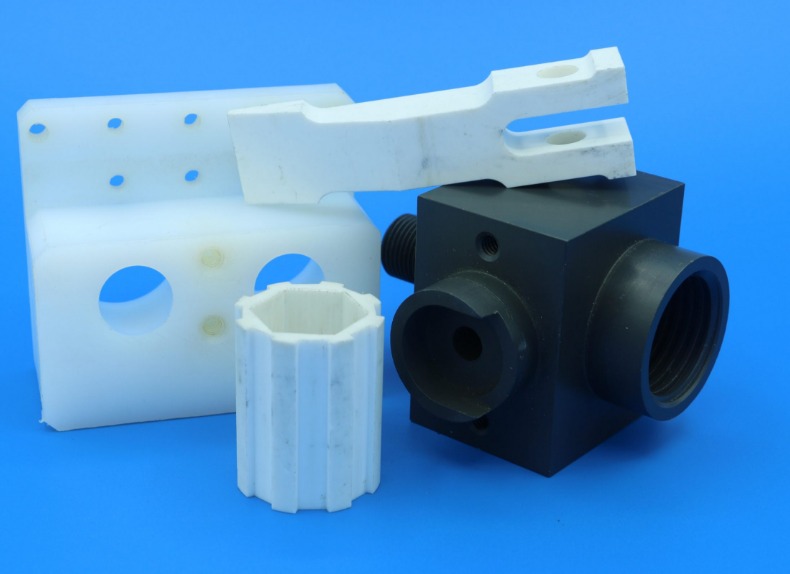

As a non - standard plastic metal products custom Supplier, Yigu Technology deeply understands the importance of precision in plastic injection moulding. We believe that precision is not just about meeting tight tolerances; it's about exceeding customer expectations.

In the field of non - standard products, every project is unique, and customers often have highly specific requirements. Our team of experienced engineers and technicians works closely with clients from the initial design phase. We use advanced 3D modeling and simulation software to optimize the mold design, ensuring that the final product will meet all the precision requirements. For example, in a recent project for a custom - designed electronic enclosure, our team was able to reduce the dimensional error to less than ±0.003 mm through meticulous design and process optimization, far surpassing the client's initial tolerance requirements.

We also place great emphasis on continuous process improvement and innovation. By investing in the latest injection - molding equipment and training our staff regularly, we are able to adapt to new challenges and technologies. Our in - house mold - making capabilities allow us to quickly modify and optimize molds, reducing lead times and ensuring the highest quality for each custom - made product. Whether it's developing new plastic - metal composite materials for better performance or implementing advanced quality control techniques, Yigu Technology is committed to delivering precision - engineered non - standard plastic metal products.

FAQs

What is the typical lead - time for plastic injection moulding products?

The typical lead - time for plastic injection moulding products can vary widely. In general, for small - scale production runs (up to a few thousand units) of relatively simple parts, the lead - time can be as short as 2 - 4 weeks. This includes the time for mold design and manufacturing (if a new mold is required), which usually takes 1 - 2 weeks, and the actual injection - molding production, which can be completed in 1 - 2 weeks. However, for large - scale production runs (tens of thousands or more units) or complex parts that require more intricate mold designs and longer production cycles, the lead - time can extend to 6 - 8 weeks or even longer. Factors such as the complexity of the mold, the availability of raw materials, and the manufacturer's production schedule can all impact the lead - time. For example, if there is a shortage of a particular type of plastic resin, it can delay the production process.

How can I ensure the quality of plastic injection moulding products?

To ensure the quality of plastic injection moulding products, start by choosing a qualified Plastic Injection Moulding Products Manufacturer with a good reputation and relevant certifications, such as ISO 9001. During the production process, closely monitor the raw materials used. Request material certificates from the manufacturer to verify that the plastic granules meet the required specifications. Conduct in - process inspections. You can ask the manufacturer to provide regular updates on the production progress and quality checks. For example, they should perform dimensional checks on the molded parts at various intervals during production. After production, carry out final quality inspections. This can include visual inspections for defects like surface finish issues, flash, or warping, as well as more in - depth dimensional and mechanical property tests using equipment like CMMs and tensile testers.

Can plastic injection moulding be used for complex - shaped products?

Yes, plastic injection moulding is well - suited for complex - shaped products. The process allows for the creation of highly detailed and intricate parts due to the ability to design molds with complex cavities. Manufacturers use advanced mold - making techniques, such as CNC machining and 3D printing for mold prototypes, to create molds that can accurately replicate the complex shapes. For example, multi - cavity molds with moving parts like slides and lifters can be used to form undercuts and other complex features. Additionally, simulation software is often employed to optimize the injection - molding process for complex - shaped parts. This software can predict potential issues such as uneven filling, warping, and air traps, allowing manufacturers to make adjustments to the process parameters before actual production. By carefully controlling factors like injection pressure, temperature, and cooling time, manufacturers can achieve high - precision production of complex - shaped plastic injection - molded products.