Selecting the right machined aluminum parts requires a strategic balance of alloy choice, machining process, surface finishing, and supplier capabilities to achieve the optimal combination of strength, weight, precision, and cost.

Machined aluminum parts form the structural and functional backbone of countless modern products, from aerospace components to consumer electronics. Aluminum’s unique combination of light weight, good strength, excellent machinability, and natural corrosion resistance makes it a first-choice material for engineers and designers. However, not all aluminum is created equal, and the path from a raw billet to a high-precision finished part is paved with technical decisions. This guide provides a comprehensive engineering perspective on specifying and sourcing machined aluminum parts. We will explore the critical properties of different alloys, dissect core CNC machining processes, compare aluminum to other metals, and outline strategies for cost optimization. Whether you are prototyping a new device or scaling production, this knowledge will empower you to make informed decisions that enhance product performance and manufacturing efficiency.

Introduction

The journey of a machined aluminum part begins long before the first tool cut. It starts with a fundamental understanding of aluminum as a material family and how its properties are harnessed through subtractive manufacturing. With a density of about 2.7 g/cm³—roughly one-third that of steel—aluminum offers an unparalleled strength-to-weight ratio. Its high thermal conductivity is a double-edged sword: beneficial for heat dissipation in electronic enclosures but a challenge for managing heat during machining. Furthermore, aluminum's tendency to form a protective oxide layer gives it inherent corrosion resistance, though this can be enhanced through various finishing processes. This article is designed to guide you through the complete lifecycle of an aluminum component, from selecting the optimal alloy for your application to implementing design strategies that reduce machining costs without compromising on the precision or quality that your project demands.

What Are Machined Aluminum Parts?

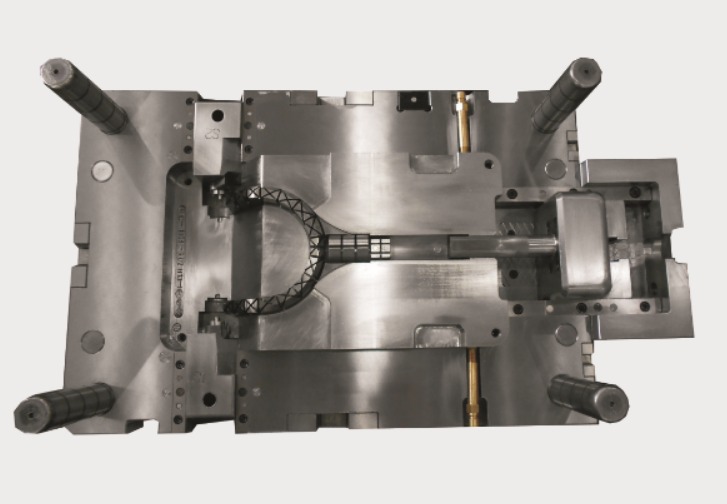

Machined aluminum parts are components manufactured by selectively removing material from a solid block (billet), bar, or near-net-shape forging of aluminum alloy using computer numerical control (CNC) machine tools. This subtractive process allows for the creation of highly complex geometries with tight tolerances that are difficult or impossible to achieve with casting or forming methods alone. The defining characteristics of these parts are their dimensional accuracy, repeatability, and superior surface integrity. Unlike cast parts, which can contain porosity or inconsistencies, machined parts are made from wrought material with a homogenous grain structure, resulting in predictable mechanical properties and enhanced reliability. Common examples range from simple brackets and spacers to complex enclosures, engine components, and optical mounts.

Which Aluminum Alloys Deliver the Best Results?

Choosing the correct alloy is the single most impactful decision in the design process. The "best" alloy is a trade-off between mechanical properties, machinability, corrosion resistance, and cost.

| Alloy & Temper | Key Properties | Machinability Rating | Ideal Applications & Notes |

|---|---|---|---|

| 6061-T6 | The "workhorse." Good strength, excellent corrosion resistance, weldable. | Good (Rating: B) | General-purpose brackets, chassis, automotive parts, frames. The most common and cost-effective choice for a wide range of uses. |

| 7075-T6 | Very high strength (comparable to many steels), good fatigue strength. | Fair (Rating: C) | Aerospace frames, high-stress structural components, competition bicycle parts. Note: Less corrosion resistant than 6061; often requires coating. |

| 2024-T3/T351 | High strength, excellent fatigue crack resistance. | Fair (Rating: C) | Aircraft structural components (skins, ribs). Superior to 7075 in fatigue applications but has poor corrosion resistance. |

| 5052-H32 | Excellent corrosion resistance (especially to salt water), good formability. | Fair/Poor (Rating: D) | Marine components, electronic enclosures, sheet metal parts. Not heat-treatable; lower strength than 6xxx/7xxx series. |

| MIC-6® (Cast) | Stress-relieved, stability-grade cast aluminum plate. | Excellent (Rating: A) | Precision ground plates, fixture plates, optical mounts. Engineered for minimal internal stress and exceptional flatness stability after machining. |

Expert Insight: A leading drone manufacturer initially specified 7075-T6 for all structural arms to maximize strength. However, after a Design for Manufacturability (DfM) review, their machining partner recommended switching non-critical brackets to 6061-T6. This single change reduced material costs by ~35% and improved machinability, cutting cycle times by 15% without any performance penalty in those specific areas.

Core CNC Machining Processes

Different part geometries demand different machining strategies. A capable supplier will select the optimal process based on the part's shape, features, and volume.

- CNC Milling (3-axis to 5-axis): The most versatile process for prismatic parts (parts based on block-like geometry). 3-axis milling machines features on the top and sides. 5-axis simultaneous milling allows the cutting tool to approach the workpiece from any angle in a single setup, enabling the creation of complex contours ideal for aerodynamic surfaces or integrated cooling channels.

- CNC Turning: The optimal process for creating rotational symmetric parts (round parts). Performed on a lathe, it is used for producing shafts, spacers, bushings, and connectors. Swiss-type lathes are a subset capable of machining very long, slender parts with extreme precision by supporting the material close to the cutting tool.

- Multi-Process/Multi-Axis Machining Centers: The most efficient solution for complex parts combines turning and milling operations in a single machine. A raw billet can be turned, milled, drilled, and tapped in one fixture, drastically reducing handling errors and total production time.

How Does Aluminum Stack Up Against Other Metals?

Aluminum is often chosen in a field of competing materials. Its advantages and limitations become clear in a direct comparison.

| Material | Density (g/cm³) | Typical Yield Strength (MPa) | Key Advantages | Common Limitations vs. Aluminum |

|---|---|---|---|---|

| Aluminum (e.g., 6061-T6) | ~2.7 | 240-280 | Light weight, good strength-to-weight, excellent corrosion resistance, high thermal/electrical conductivity, good machinability. | Lower absolute strength and stiffness (modulus) than steel; lower maximum service temperature. |

| Steel (e.g., 304 Stainless) | ~7.9 | 215-310 | Much higher strength and hardness, higher temperature resistance, generally lower material cost. | Over 3x heavier, prone to rust (unless stainless), lower thermal conductivity, more difficult and slower to machine. |

| Titanium (e.g., Ti-6Al-4V) | ~4.5 | 830-900 | Exceptional strength-to-weight, excellent corrosion resistance, biocompatible. | Very high material cost (5-10x aluminum), very difficult to machine (low thermal conductivity causes heat buildup), expensive tooling. |

| Magnesium (e.g., AZ31B) | ~1.7 | 160-200 | The lightest structural metal (35% lighter than Al), good damping capacity. | Lower strength, poor corrosion resistance (requires coating), flammable machining chips, higher material cost than Al. |

The choice often comes down to the primary design driver. For a satellite component, where every gram counts, aluminum or magnesium wins. For a high-wear hydraulic piston, steel's hardness is superior. For a biomedical implant, titanium's biocompatibility is essential.

What Surface Finishing Options Exist?

Finishing enhances appearance, functionality, and longevity. The choice depends on the desired aesthetic, environmental exposure, and dimensional requirements.

- As-Machined/Bead Blasted: The most economical option. A bead-blasted finish provides a uniform matte appearance and can mask minor tool marks.

- Anodizing (Type II & III): An electrochemical process that grows a hard, porous aluminum oxide layer.

- Type II (Decorative): Provides corrosion resistance and allows for dyeing in various colors (black, blue, red, etc.).

- Type III (Hard Coat): Creates a much thicker, harder coating for extreme wear resistance. It adds 0.025-0.050 mm per surface, which must be accounted for in the machining tolerance ("pre-sized").

- Powder Coating: A dry powder is electrostatically applied and cured into a hard, durable polymer layer. Offers superior color and texture options and excellent corrosion protection, but adds more thickness than anodizing.

- Chemical Film (Chromate Conversion): A thin, conductive coating (often iridescent gold or green) that provides good corrosion resistance and serves as an excellent primer for paint. Common in aerospace (specified as MIL-DTL-5541).

Achieving Precision: Tolerances and Quality Control

The achievable precision in aluminum is very high but is influenced by the part's geometry and the machining process.

- Standard vs. Precision Tolerances: For a typical machined aluminum part, ±0.005" (0.13 mm) is a standard, economical tolerance. Precision machining can consistently hold ±0.001" (0.025 mm) or tighter on critical features. Holding ±0.0005" (0.0127 mm) is possible but requires specialized processes and significantly increases cost.

- Managing Thermal Expansion: Aluminum has a high coefficient of thermal expansion (~24 µm/m·°C). A 100 mm part will expand 2.4 µm for every 1°C rise. High-precision machining requires a temperature-controlled shop and allows parts to normalize to room temperature before final finishing cuts and inspection.

- Quality Control Verification: Precision is proven with data. Reliable suppliers use Coordinate Measuring Machines (CMMs) for comprehensive First Article Inspection (FAI) and Statistical Process Control (SPC) to monitor dimensions during production runs, ensuring consistency.

How Can Machining Costs Be Optimized?

Cost is driven by material, machine time (cycle time), and overhead. Smart design choices can significantly reduce all three.

- Design for Machinability (DfM): This is the most powerful tool for cost reduction. Engage your supplier early.

- Minimize Setups: Design parts that can be machined in as few setups as possible. Complex 5-axis parts may have a higher machine rate but can be cheaper overall than a simple part requiring 4 separate fixtures on a 3-axis mill.

- Avoid Excessive Tolerances: Only specify tight tolerances where they are functionally critical. Every callout of ±0.001" adds cost for slower machining, specialized tooling, and increased inspection.

- Choose Standard Stock Sizes: Design parts that can be made from readily available bar or plate sizes. Needing a 51 mm thick plate when only 50 mm or 63 mm is standard adds cost for custom milling the stock.

- Consider Alternative Processes for Features: For deep, small holes, consider specifying them as a post-machining EDM (Electrical Discharge Machining) operation rather than a long, fragile drill on a CNC mill, which can break and scrap the part.

Key Applications Across Industries

The properties of machined aluminum parts make them indispensable in several high-tech fields:

- Aerospace & Aviation: Airframe components (ribs, brackets), engine mounts, UAV frames, and satellite hardware. Alloys like 7075 and 2024 are staples for their high strength-to-weight ratio.

- Automotive & Motorsports: High-performance engine blocks (often using A356 cast billet), suspension components, turbocharger housings, and custom brackets. Lightweighting is key for efficiency and performance.

- Consumer Electronics: Laptop chassis, smartphone structural frames, heat sinks, and camera housings. Aluminum provides a premium feel, EMI shielding, and excellent heat dissipation.

- Medical Devices: MRI machine components (non-magnetic), surgical instrument handles, and mobile cart frames. The ease of sterilization and cleanability of anodized aluminum is a major benefit.

- Industrial & Robotics: Robotic arm links, sensor mounts, and fixture plates. Aluminum's stiffness and light weight allow for faster, more energy-efficient robotic movement.

What Should You Look for in a Supplier?

The right supplier turns a good design into a great part. Look for these capabilities:

- Material Expertise: They should proactively discuss alloy options and temper states, not just accept your initial specification.

- Advanced Multi-Axis Capability: For complex parts, ensure they have true 5-axis machining experience, not just 3+2 indexing.

- Comprehensive In-House Finishing: A supplier with anodizing and other finishing lines in-house has better control over quality, lead time, and logistics.

- Robust Quality Systems: Ask for examples of their First Article Inspection Reports and if they use SPC. Certifications like AS9100 (aerospace) or ISO 13485 (medical) are strong indicators of a mature quality culture.

- Proactive DfM Mindset: The best suppliers will provide unsolicited, constructive feedback on your design to improve manufacturability and reduce cost.

Conclusion

Specifying and sourcing machined aluminum parts is a multifaceted engineering challenge that balances material science, manufacturing processes, and economic reality. By understanding the distinct roles of alloys like 6061-T6 and 7075-T6, leveraging multi-axis CNC processes, applying appropriate surface finishes, and implementing smart Design for Machinability principles, you can unlock the full potential of this versatile material. Partnering with a supplier who possesses both the technical capabilities and a collaborative engineering mindset is crucial for transforming your designs into high-performance, reliable, and cost-effective components. With this comprehensive guide, you are equipped to make informed decisions that will enhance your product from the ground up.

Frequently Asked Questions (FAQ)

What is the main difference between 6061 and 7075 aluminum for machining?

6061-T6 is the general-purpose alloy with good strength, excellent corrosion resistance, and very good machinability. It's weldable and cost-effective. 7075-T6 is a high-strength alloy with strength comparable to many steels, but it has lower corrosion resistance and is slightly more challenging to machine. Use 7075 where maximum strength-to-weight is critical (aerospace, high-stress parts); use 6061 for most other applications.

How does anodizing affect the dimensions of a machined aluminum part?

Anodizing adds thickness. Type II (decorative) anodizing adds a negligible amount (a few microns). Type III (hard coat) anodizing typically adds 0.025 mm to 0.050 mm (0.001" to 0.002") per surface. For parts with critical dimensions, the machinist must "pre-size" the part by machining it undersize by the expected anodize thickness. Always discuss finishing requirements with your machinist before finalizing tolerances.

Can threaded holes be anodized?

Yes, but with caution. The anodize buildup inside a tapped hole will reduce its effective size and can cause fasteners to bind or not fit. For threaded holes that must be anodized, common practices include: 1) Masking the threads with a plug during anodizing, 2) Oversizing the tap drill slightly to account for the coating, or 3) Chasing the threads with a tap after anodizing (which can chip the coating). Your supplier should guide you on the best method.

Is aluminum or stainless steel stronger for machined parts?

By absolute strength, stainless steel is generally stronger. For example, 304 stainless has a similar yield strength to 6061 aluminum but is three times denser. However, when considering strength-to-weight ratio, aluminum alloys like 7075-T6 are superior to many steels. The choice depends on whether your design is weight-sensitive (favoring aluminum) or requires maximum absolute strength and wear resistance in a compact space (favoring steel).

Contact Yigu Technology for Custom Manufacturing.

At Yigu Technology, we specialize in transforming your innovative designs into high-performance machined aluminum parts. Our expertise goes beyond simple machining; we are your engineering partner in material selection, design optimization, and precision manufacturing.

We maintain a deep inventory of aerospace and commercial-grade aluminum alloys and operate a fleet of advanced multi-axis CNC machining centers capable of producing everything from simple prototypes to complex, high-volume production components. Our in-house anodizing and finishing department ensures seamless quality control and rapid turnaround.

Ready to elevate your product with precision-machined aluminum components? Contact Yigu Technology today for a comprehensive design review and quote. Let our team help you optimize for performance, durability, and cost.