What is SLS Printing?

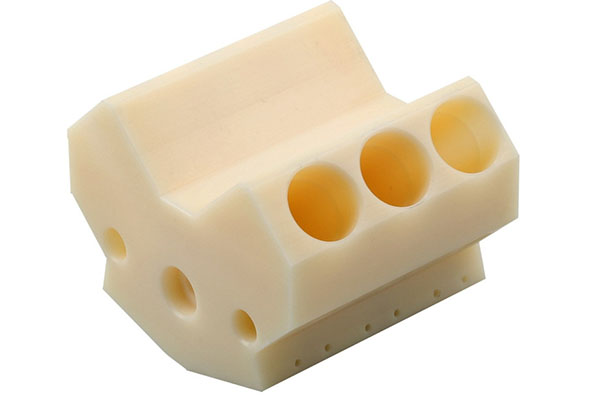

SLS printing, short for Selective Laser Sintering, is a revolutionary 3D printing technology that has been making waves in various industries. It belongs to the family of powder bed fusion 3D printing techniques.

The Basic Principle

At its core, SLS printing works by using a high - power laser to sinter powdered materials together. The process starts with a bed filled with a thin layer of powdered material, which can be plastics like nylon (PA), polypropylene (PP), or even metal powders in some advanced SLS systems. A laser beam, directed by a computer - controlled scanning system, selectively heats and fuses the powder particles according to the cross - sectional shape of the 3D model being printed. As the laser scans, the powder particles in the targeted areas reach their melting or sintering temperature, causing them to bond together. Once one layer is completed, the build platform lowers by a small increment (usually in the range of 0.05 - 0.3 mm), a new layer of powder is spread over the previously sintered layer, and the laser - sintering process repeats. This layer - by - layer construction gradually builds up the 3D object. For example, if you are printing a complex mechanical part, the laser will first sinter the bottom - most layer of the part's shape into the powder bed, and then proceed to build the layers above it, one by one.

How it Differs from Other 3D Printing Methods

Compared to Fused Deposition Modeling (FDM), which extrudes melted filament to create layers, SLS doesn't require support structures for overhangs and complex geometries. This is because the unsintered powder supports the printed part during the process. In contrast, FDM often needs additional support structures that must be removed later, which can be time - consuming and may sometimes damage the printed object. Another popular 3D printing method, Stereolithography (SLA), uses a liquid resin cured by a UV laser. SLA is known for its high - resolution and smooth surface finish, but it is mainly limited to resin materials. SLS, on the other hand, offers a wider range of material options and can produce parts with better mechanical properties in many cases, making it more suitable for functional prototypes and end - use parts in industries such as automotive and aerospace.

Applications of SLS Printed Parts

SLS printed parts have found their way into a wide range of industries, revolutionizing the way products are designed, prototyped, and manufactured. Here are some of the key applications:

Aerospace

In the aerospace industry, weight reduction is crucial for improving fuel efficiency and performance. SLS printed parts offer significant advantages in this regard. For example, NASA has been exploring the use of SLS - printed components for its space missions. They can produce complex, lightweight parts with internal lattice structures that are impossible to manufacture using traditional methods. These lattice - structured parts not only reduce weight but also maintain high strength - to - weight ratios. A case in point is the production of engine components. SLS - printed engine brackets can be designed with optimized geometries, reducing their mass by up to 30% compared to conventionally manufactured ones, while still meeting the rigorous mechanical requirements of space travel. This weight reduction directly contributes to lower fuel consumption during launches and extended mission capabilities.

Automotive

The automotive industry also benefits greatly from SLS printed parts. One of the main applications is in the production of custom - designed prototypes. Car manufacturers can quickly create functional prototypes of new components such as intake manifolds, brackets, and interior parts using SLS technology. This speeds up the design - validation process, allowing engineers to test and refine their designs in a shorter time frame. For instance, a major automotive company was able to reduce the time to develop a new intake manifold prototype from several weeks (using traditional manufacturing) to just a few days with SLS printing. Additionally, SLS - printed parts can enhance the performance of race cars. Lightweight, high - strength components printed through SLS can improve the power - to - weight ratio of race cars, leading to better acceleration, handling, and overall race performance.

Medical

In the medical field, SLS printed parts are making a significant impact, especially in the area of customized medical devices and prosthetics. For patients with unique anatomical needs, SLS printing enables the creation of personalized prosthetics that fit perfectly. By using 3D scanning technology to capture the patient's body geometry, medical professionals can design and print prosthetics with a high level of precision. For example, a patient with an amputated limb can receive a custom - printed prosthetic socket that conforms exactly to the shape of their residual limb, providing a more comfortable and secure fit. This reduces the risk of skin irritation and improves the patient's mobility. SLS - printed medical devices also include surgical guides. These guides are designed to assist surgeons during complex procedures, ensuring accurate placement of implants or precise incisions. They are customized based on the patient's specific anatomy, leading to more successful surgeries and faster patient recoveries.

Comparison with Other 3D Printing Methods

Yigu Technology's Viewpoint

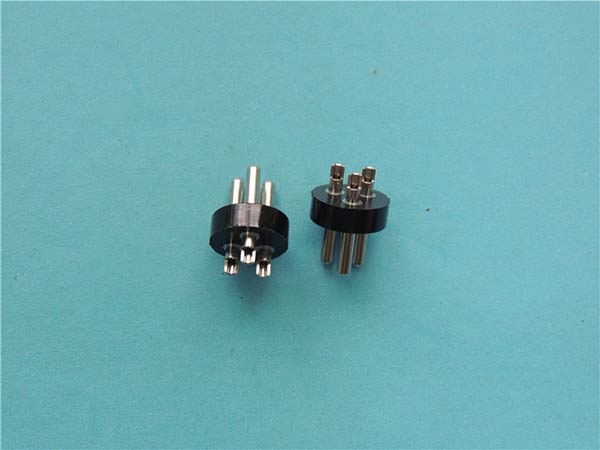

As a non - standard plastic metal products custom Supplier, Yigu Technology firmly believes in the remarkable potential of SLS printed parts in custom - made production. SLS technology allows for the creation of highly customized parts with complex geometries, which is a game - changer for non - standard product manufacturing. It enables us to quickly turn our clients' unique designs into physical prototypes and end - use products, significantly reducing the lead time compared to traditional manufacturing methods.

Moreover, the wide range of available materials in SLS printing, such as plastics and certain metal powders, offers more options for different application requirements. Whether it's for creating lightweight plastic components with high strength - to - weight ratios or metal parts with excellent mechanical properties, SLS printing can meet the needs. We envision SLS printed parts playing an even more significant role in the future, especially as the demand for customized, high - performance products continues to grow in various industries.

FAQ about SLS Printed Parts

What materials can be used for SLS printing?

Common materials for SLS printing include plastics like nylon (PA), which is widely used due to its good mechanical properties, such as high strength and toughness. Polypropylene (PP) is another option, offering chemical resistance and relatively low cost. TPU (Thermoplastic Polyurethane) can also be used in SLS printing, providing excellent flexibility and durability, making it suitable for applications like flexible gaskets or shoe soles. In some advanced SLS systems, metal powders such as aluminum, titanium, and stainless - steel powders are available for producing high - strength metal parts, although metal SLS printing often requires more complex equipment and processing conditions.

How accurate are SLS printed parts?

The accuracy of SLS printed parts typically ranges from ±0.1mm to ±0.2mm. For example, in some high - end SLS printers, when printing small - sized parts with relatively simple geometries, an accuracy of around ±0.1mm can be achieved. However, as the size of the part increases or the geometry becomes more complex, the accuracy may decrease slightly to around ±0.2mm. Factors such as the quality of the SLS equipment, the type of powder material used, and the printing process parameters all influence the final accuracy of the printed parts.

Is SLS printing suitable for large - scale production?

SLS printing has both advantages and limitations for large - scale production. On the one hand, SLS can produce complex parts without the need for expensive molds, which is beneficial for small - batch, high - variety production. It allows for quick design changes and customization, reducing the time and cost associated with traditional manufacturing methods for each new design. On the other hand, SLS printing has a relatively slow build speed compared to some mass - production techniques like injection molding. The cost of SLS equipment is high, and the materials are also relatively expensive. For example, high - quality nylon powder for SLS can cost significantly more per kilogram than traditional injection - molding plastics. Therefore, while SLS can be used for small - to medium - scale production runs, especially for parts with complex geometries or where customization is key, it may not be the most cost - effective or efficient choice for large - scale, high - volume production of simple parts.