Introduction to CNC Turning Parts Manufacturing

CNC (Computer Numerical Control) turning is a critical process in modern manufacturing, offering high precision and repeatability. This method involves rotating a workpiece while a cutting tool moves along multiple axes to remove material, resulting in the desired part geometry. CNC turning is used in industries that demand high-quality, intricate components with tight tolerances.

This article explores the leading CNC turning parts manufacturers in the industry, evaluating their quality standards, speed of service, and reliability. We’ll provide an in-depth comparison of these manufacturers, focusing on their capabilities, materials, and precision to help you identify the best fit for your turning parts needs.

Overview of the CNC Turning Process

CNC turning starts with the creation of a Computer-Aided Design (CAD) model of the part. The design is then converted into a format that the CNC machine can interpret, typically using Computer-Aided Manufacturing (CAM) software. The machine reads the instructions and operates with high precision, guiding a rotating workpiece while the cutting tool moves linearly to remove material.

During the turning operation, the workpiece is clamped by a chuck or collet, and the cutting tool, which can be mounted on a turret, follows the programmed paths along the X, Y, and Z axes. After the turning process, additional operations such as drilling, milling, or threading may be performed. Quality inspection ensures the final part meets customer specifications before shipment.

Key Attributes of Top Manufacturers

When evaluating CNC turning parts manufacturers, the following attributes are essential:

Quality Standards and Certifications

Top-tier CNC turning manufacturers must adhere to international quality standards, showcasing their commitment to excellence. Common certifications include:

- ISO 9001: Ensures consistent quality management across production.

- AS9100: Specific to the aerospace industry, ensuring compliance with high standards.

- ITAR Compliance: Relevant for manufacturers handling sensitive, military-grade components.

These certifications indicate that the manufacturer has robust quality control systems in place to maintain high standards throughout production.

Speed of Service and Delivery Times

In today’s competitive landscape, quick turnaround times are essential. Leading manufacturers leverage advanced CNC machinery and optimized workflows to reduce production times. Many also offer expedited shipping options to meet tight project deadlines. Speed does not come at the expense of quality, as these manufacturers ensure fast service without compromising precision.

Materials and Capabilities

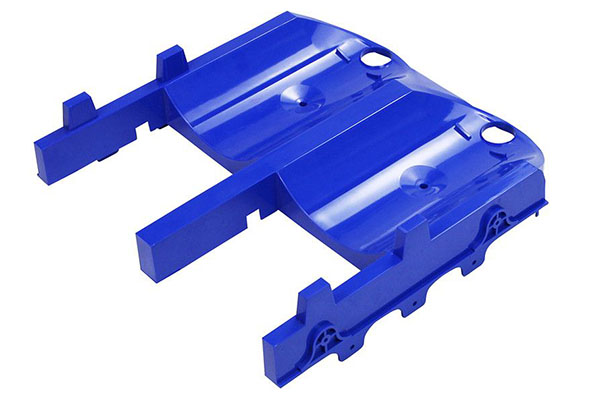

Manufacturers who offer a wide range of material options and are capable of producing parts with complex designs stand out in the CNC turning space. The best manufacturers can work with metals, alloys, plastics, and composites. Additionally, their ability to create parts with intricate geometries and tight tolerances enhances their appeal.

Customization and Bespoke Services

Customization is a crucial factor when selecting a CNC turning manufacturer. Leading manufacturers provide a variety of services including surface finishes, coatings, and secondary operations. They also offer bespoke solutions for unique applications, ensuring that every part meets specific customer requirements.

Materials and Capabilities

Types of Materials Used in CNC Turning

CNC turning can be performed on a variety of materials, each chosen based on the part’s intended use:

- Metals: Aluminum, stainless steel, titanium, brass, copper, and carbon steel are commonly used for turning parts.

- Alloys: Special alloys such as Inconel, Hastelloy, Monel, and various aluminum and titanium alloys are preferred for high-stress, high-temperature applications.

- Plastics: Materials like ABS, Delrin, Nylon, PEEK, and Teflon are used for parts that need to be lightweight, durable, and resistant to chemical wear.

- Composites: Advanced materials like carbon fiber composites are used for parts that require high strength-to-weight ratios.

The machinability of these materials varies, which affects the choice of cutting tools, speeds, and feeds used during the CNC turning process.

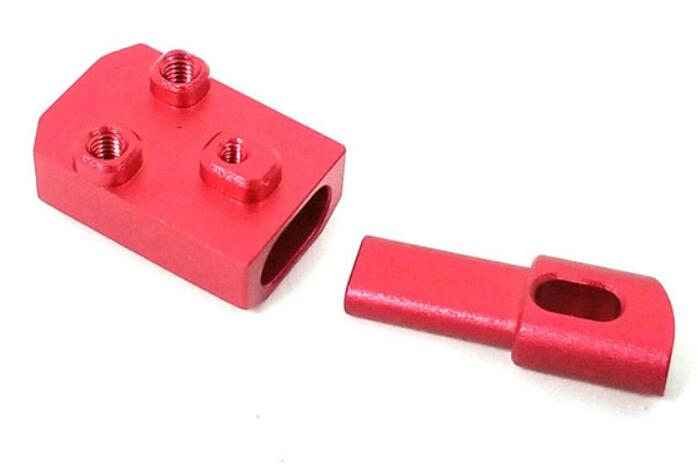

Complexity and Precision of Parts Manufactured

CNC turning is capable of producing parts with very intricate shapes and designs, including complex geometries, threads, grooves, and undercuts. Precision and tolerance are critical in this process and are often defined by how closely the final part matches its design specifications.

Precision and Tolerance

Precision refers to the degree of accuracy in producing a part, while tolerance refers to the acceptable deviation from the target dimensions. The tighter the tolerance, the higher the precision. Leading manufacturers can achieve tolerances as tight as ±0.0001 inches for high-performance parts, such as those used in aerospace and medical devices.

The Importance of Tolerance in CNC Turning

Maintaining tight tolerance is essential to ensure parts fit together properly and function as intended, particularly in industries where failure can lead to significant risks, such as aerospace and medical devices. A slight deviation from the required dimension can result in malfunction, performance degradation, or even catastrophic failure.

Precision Levels Offered by Manufacturers

Manufacturers differentiate themselves based on their ability to achieve high precision. Companies investing in advanced CNC machinery and skilled technicians can produce parts with extremely tight tolerances. Tools like Coordinate Measuring Machines (CMMs) and optical comparators are used to ensure that every part meets the required specifications.

Customization and Bespoke Services

Customization Options for Turning Parts

Customization allows customers to tailor parts to meet unique requirements. Some of the most common customization options include:

- Surface Finishes: Anodizing, polishing, powder coating, electroplating, and other surface treatments enhance both aesthetics and functionality.

- Secondary Operations: Operations like drilling, tapping, milling, and broaching can be performed to achieve additional features.

- Heat Treatment: Processes like annealing, quenching, and tempering improve the material's properties.

- Plating: Various types of plating, such as zinc, nickel, and gold, can be applied to protect parts from corrosion and wear.

These services enhance the functionality, aesthetics, and durability of the parts, ensuring they meet both performance and visual standards.

Bespoke Solutions for Specific Applications

Top manufacturers often provide bespoke solutions for challenging projects. This may include developing custom tooling, fixtures, and jigs designed specifically to hold and manipulate the workpiece during the CNC turning process. Custom solutions ensure that even highly complex or non-standard parts are produced with high precision.

Industry Applications

Sectors Served by CNC Turning Parts Manufacturers

CNC turning parts serve a broad range of industries due to their versatility, precision, and ability to meet specific requirements. Major sectors include:

- Automotive: For manufacturing engine components, transmission parts, and braking systems.

- Aerospace: For producing critical components such as airframe parts, landing gear, and turbine blades.

- Medical Devices: For creating surgical instruments, implants, and diagnostic tools.

- Electronics: For parts like connectors, housings, and sensor components.

- Energy: For producing turbine blades, oilfield equipment, and other high-performance components.

- Machinery: For bearings, gears, actuators, and more.

Examples of Turned Parts in Various Industries

- Automotive: Parts like crankshafts, valve stems, and piston rods are integral to engine performance.

- Aerospace: Components such as turbine blades and landing gear must meet extremely high standards for strength and precision.

- Medical Devices: Surgical tools and implants demand both high precision and biocompatibility.

- Electronics: Parts like switch actuators and connector pins require precise dimensions for reliable electrical connections.

- Energy: Parts such as wind turbine shafts and oil drill bits must withstand harsh environmental conditions.

- Machinery: Components like bearings and gears are essential for smooth operation in machines and equipment.

Conclusion: Selecting the Right CNC Turning Parts Manufacturer

Choosing the best CNC turning parts manufacturer for your needs requires careful consideration of several factors:

Summary of Key Considerations for Choosing a Manufacturer

- Quality Standards and Certifications: Look for manufacturers with ISO 9001, AS9100, or ITAR certifications.

- Material Expertise: Ensure the manufacturer has experience with the specific materials you require.

- Precision and Tolerance: Evaluate the manufacturer’s ability to meet your precision needs.

- Customization Options: Ensure the manufacturer offers a wide range of customization services to meet unique requirements.

- Turnaround Time: Consider the manufacturer’s ability to meet deadlines without compromising quality.

- Reputation and Reviews: Research customer feedback to gauge reliability and service quality.

- Cost-Effectiveness: Compare quotes from multiple manufacturers for competitive pricing.

- Technical Support: Choose a manufacturer that provides strong technical support throughout the production process.

- Industry Experience: Prefer manufacturers with a proven track record in your industry for tailored solutions.

- Scalability: Ensure the manufacturer can scale production up or down based on your needs.

By carefully evaluating these factors, you can select the CNC turning parts manufacturer that best aligns with your project requirements, ensuring high-quality, reliable, and cost-effective parts for your application