Introduction

In the ever - evolving landscape of modern manufacturing, rapid manufacturing has emerged as a revolutionary approach. Rapid manufacturing, also known as RM, is an advanced manufacturing technology based on the discrete - accumulation forming principle. It can directly drive the assembly (accumulation) of material units from the three - dimensional CAD model data of a product to manufacture arbitrarily complex and functional parts. This technology has brought about a paradigm shift, enabling companies to produce products faster, more efficiently, and with greater design flexibility compared to traditional manufacturing methods.

Rapid Manufacturing Inc is a key player in this field, leveraging state - of - the - art technologies and innovative processes to offer a wide range of rapid manufacturing solutions. In this article, we will explore the diverse applications of Rapid Manufacturing Inc, uncovering how this company is shaping the future of manufacturing across multiple industries.

Aerospace Industry Applications

Component Prototyping

In the aerospace industry, the demand for high - performance and lightweight components is crucial. Rapid manufacturing plays a vital role in creating prototypes of complex aerospace components. For example, engine blades are some of the most complex parts in an aircraft engine. These blades need to withstand extreme temperatures, high rotational speeds, and intense mechanical stress. With rapid manufacturing, companies like Rapid Manufacturing Inc can produce highly accurate prototypes of engine blades. By using advanced 3D printing techniques and high - temperature - resistant materials, they can replicate the intricate internal cooling channels and aerodynamic shapes of the blades precisely.

Another example is the aerospace electronics enclosures. These enclosures need to protect sensitive electronic components from electromagnetic interference, vibrations, and harsh environmental conditions. Rapid manufacturing allows for the production of custom - designed enclosures with unique features such as integrated heat sinks and precise cutouts for connectors. Traditional manufacturing methods would require expensive molds and long lead times for such custom designs, but rapid manufacturing can create these enclosures in a fraction of the time.

Customized Tooling

Aerospace manufacturing often requires specialized tooling to meet the unique needs of each project. Rapid manufacturing enables the production of customized tooling that is tailored to specific aerospace applications. For instance, fixtures used in the assembly of aircraft wings need to hold the components in precise positions during the manufacturing process.

Compared to traditional tool - making methods, which typically involve machining from solid blocks of metal, rapid manufacturing offers several advantages. Firstly, it can significantly reduce the lead time. Traditional tool - making may take weeks or even months, especially for complex tools, while rapid manufacturing can produce the same tool in a matter of days or even hours in some cases. Secondly, rapid manufacturing can create tools with complex geometries that are difficult or impossible to achieve with traditional machining. This allows for more efficient and accurate manufacturing processes in the aerospace industry. Additionally, the cost of producing customized tools through rapid manufacturing can be much lower, especially for low - volume production runs.

Medical Field Applications

Prosthetics and Implants

In the medical field, rapid manufacturing has opened up new possibilities for the production of prosthetics and implants. For patients who require prosthetics, one - size - fits - all solutions are no longer the only option. With rapid manufacturing, prosthetics can be custom - made to fit the unique anatomy of each patient precisely.

For example, a patient who has lost a limb due to an accident or disease can benefit greatly from a custom - made prosthetic limb. Using 3D scanning technology, the shape and size of the residual limb can be accurately captured. Then, Rapid Manufacturing Inc can use this data to create a prosthetic limb through 3D printing. This ensures a better fit, which in turn improves the comfort and functionality of the prosthetic. According to a study, patients who used custom - made prosthetics made through rapid manufacturing reported a 30% increase in their ability to perform daily activities compared to those using standard prosthetics.

When it comes to implants, rapid manufacturing allows for the creation of complex and personalized implants. Dental implants, for instance, can be designed to match the exact shape and structure of a patient's jawbone. This not only improves the success rate of the implant surgery but also reduces the risk of complications. In the past, traditional manufacturing methods made it difficult to produce implants with such high - level customization. Now, rapid manufacturing enables the production of implants with porous structures that promote better bone integration, leading to a more stable and long - lasting implant.

Surgical Instrument Prototyping

The development of new surgical instruments is a crucial aspect of medical progress. Rapid manufacturing plays a significant role in surgical instrument prototyping. Surgeons and medical device companies can use rapid manufacturing to quickly create prototypes of new surgical instruments.

For example, if a surgeon has an idea for a new laparoscopic instrument that can perform a specific procedure more effectively, they can work with a company like Rapid Manufacturing Inc to create a prototype. The 3D printing technology can produce the instrument prototype in a short period, allowing for quick testing and refinement. This iterative process of prototyping, testing, and improving is much faster and more cost - effective with rapid manufacturing compared to traditional manufacturing methods.

In a case study, a medical device company was able to reduce the time it took to develop a new surgical stapler from 18 months to just 6 months by using rapid manufacturing for prototyping. This acceleration in the development process can bring new and improved surgical instruments to the market faster, ultimately benefiting patients and the medical community as a whole. It also encourages innovation in the medical field, as the barriers to prototyping new ideas are significantly reduced.

Automotive Sector Applications

Concept Car Development

In the automotive sector, rapid manufacturing has become an indispensable tool, especially in the initial stages of vehicle development. When it comes to concept car development, speed and flexibility are crucial. Rapid Manufacturing Inc offers a range of solutions that enable automotive designers to bring their ideas to life quickly.

Using 3D printing and other rapid manufacturing techniques, designers can create physical models of concept cars in a short time. These models are not only useful for visualizing the design but also for conducting aerodynamic tests. For example, a concept car's body shape needs to be optimized for minimum air resistance. By creating a 3D - printed model, engineers can place it in a wind tunnel and measure the air flow around it. This allows for quick design iterations. In the past, creating a concept car model using traditional methods such as hand - carving or using expensive molds could take months. With rapid manufacturing, the same model can be produced in a matter of weeks or even days, reducing the overall development time and cost. A study showed that automotive companies that adopted rapid manufacturing for concept car development were able to reduce their design - to - prototype time by up to 50%.

Small - batch Production of Special Parts

Another significant application of rapid manufacturing in the automotive industry is the small - batch production of special parts. In today's market, there is an increasing demand for customized and high - performance automotive parts. For instance, some car enthusiasts or racing teams require unique parts that are not mass - produced.

Rapid manufacturing allows for the production of these special parts without the need for large - scale tooling and high - volume production runs. Take a custom - designed intake manifold for a high - performance engine as an example. Using traditional manufacturing methods, producing a small batch of such manifolds would be extremely costly due to the need to create dedicated molds. With rapid manufacturing, parts like this can be produced directly from a digital design, layer by layer. This not only reduces the cost but also enables quick modifications if needed. According to industry reports, the cost of producing small - batch special automotive parts through rapid manufacturing can be up to 70% lower compared to traditional manufacturing methods, while still maintaining high - quality standards.

Industrial Equipment Manufacturing Applications

Rapid Production of Spare Parts

In industrial equipment manufacturing, the timely availability of spare parts is crucial for maintaining the smooth operation of production lines. Any delay in obtaining a replacement part can lead to significant downtime, resulting in substantial financial losses. This is where rapid manufacturing proves to be a game - changer.

Rapid Manufacturing Inc can quickly produce spare parts for industrial equipment using advanced 3D printing and other rapid manufacturing techniques. For example, in a large - scale chemical plant, a critical pump impeller suddenly fails. Traditional methods of ordering a replacement impeller from the original equipment manufacturer may take weeks, considering the production lead time, shipping, and customs procedures. However, with rapid manufacturing, the plant can provide the digital design of the impeller (which can be retrieved from its CAD database or created through reverse engineering if the original design is lost). Rapid Manufacturing Inc can then produce a new impeller in a matter of days, or even hours in some cases. This significantly reduces the downtime of the chemical plant. According to industry statistics, on average, for every hour of production downtime in a large - scale manufacturing facility, the cost can range from \(10,000 to \)250,000, depending on the industry and the complexity of the production process. By using rapid manufacturing for spare part production, companies can potentially save hundreds of thousands of dollars in lost production revenue.

Custom - built Machinery Components

Every industrial process has its unique requirements, and sometimes, off - the - shelf machinery components may not be sufficient. This is where the ability to produce custom - built machinery components through rapid manufacturing becomes invaluable.

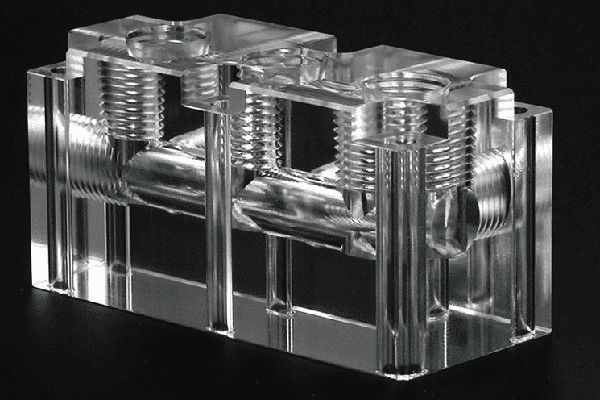

Rapid Manufacturing Inc can create components tailored to specific industrial processes. Take the example of a textile manufacturing company that wants to improve the efficiency of its weaving machines. They may require a custom - designed shuttle component that can move more smoothly and at a higher speed within the weaving mechanism. With rapid manufacturing, the company can work closely with Rapid Manufacturing Inc to design a shuttle component with optimized aerodynamics and material properties. The 3D printing process allows for the creation of complex internal structures and geometries that are difficult to achieve with traditional manufacturing methods. This custom - built shuttle can then be produced quickly and cost - effectively. In contrast, traditional manufacturing methods such as casting or forging would require expensive tooling and long lead times for such a custom - designed component.

In another case, a metal - processing plant may need a custom - built die for a unique metal - stamping operation. The die needs to have a very precise shape and surface finish to ensure high - quality stamping results. Rapid manufacturing can produce this die with the exact specifications required, enabling the plant to carry out its specialized stamping process efficiently. The flexibility of rapid manufacturing in creating custom - built machinery components means that industrial equipment manufacturers can better meet the diverse and evolving needs of their customers, ultimately enhancing their competitiveness in the market.

Yigu Technology's View

As a non - standard plastic metal products custom Supplier, Yigu Technology highly values the application of rapid manufacturing. In the production of non - standard plastic and metal products, rapid manufacturing enables us to achieve higher product precision. For example, through 3D printing, we can accurately control the dimensions of complex - shaped plastic components within a tolerance of ±0.1mm, which is difficult to achieve with traditional manufacturing methods.

Moreover, rapid manufacturing significantly shortens the delivery cycle. In the past, producing a custom - made metal part might take weeks due to the need for mold - making and multiple processing steps. Now, with rapid manufacturing, we can complete the production and delivery in just a few days. This not only improves our competitiveness but also better meets the urgent needs of customers. It also allows for more cost - effective production of small - batch non - standard products, reducing waste and unnecessary production costs.

FAQ

1. What materials can Rapid Manufacturing Inc use for production?

Rapid Manufacturing Inc can use a wide range of materials, including various plastics like ABS, PLA, and high - performance engineering plastics. For metal components, materials such as aluminum, titanium, and stainless steel can be used. In the medical field, biocompatible materials like certain polymers for prosthetics and special alloys for implants are also utilized.

2. How accurate are the products produced by rapid manufacturing?

The accuracy can be extremely high. In general, for many common rapid manufacturing processes, the dimensional accuracy can reach ±0.1 - 0.2mm for small - to medium - sized parts. In some high - precision applications, such as aerospace component prototyping, the accuracy can be further improved to meet the strict requirements of the industry.

3. Is rapid manufacturing suitable for large - scale production?

While rapid manufacturing is more commonly associated with small - batch production, prototyping, and custom - made products, in some cases, it can also be used for large - scale production. For example, when the product design requires frequent changes or the production volume is not extremely high, rapid manufacturing can offer cost - effective solutions. However, for mass - production of simple and standardized products, traditional manufacturing methods may still be more cost - efficient in terms of unit cost.