What Exactly is Rapid Manufacturing Inc?

Rapid Manufacturing Inc is a globally recognized electronics manufacturing powerhouse. Since its establishment in 1976 with its headquarters based in the United States, it has been at the forefront of the industry for over 50 years.

Core Business

The company specializes in electronic custom - designed wire & cable harnesses, electro - mechanical, and box build assemblies for Original Equipment Manufacturers (OEMs). It is a master in the design and assembly of wires, cables, and wire harnesses. For instance, in the production of wire harnesses, it can handle complex designs that require precise routing of multiple wires to ensure seamless connectivity in various devices.

Industry Status

Rapid Manufacturing Inc has a significant industrial footprint across the Americas, China, and Southeast Asia, with a workforce of over 2,000 employees. It serves a wide range of industries including Medical, Aerospace, Semiconductor, Industrial, Defence, and Renewable Energy. In the medical field, its wire harnesses are used in life - saving equipment such as MRI machines and surgical robots, where high reliability and quality are non - negotiable. In aerospace, its components are part of critical aircraft systems, contributing to flight safety and performance.

The Core Business Scope

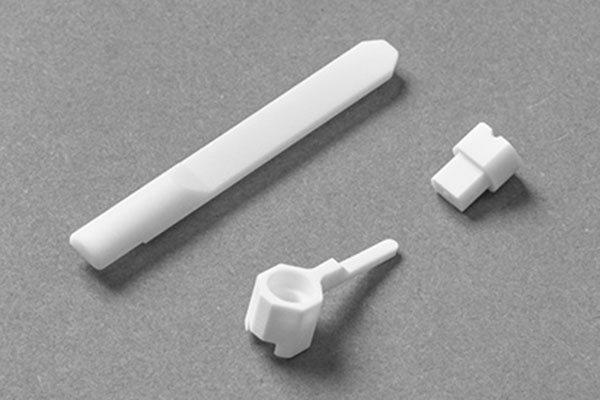

Custom - designed Wire & Cable Harnesses

Rapid Manufacturing Inc excels in custom - designed wire & cable harnesses. The company's expertise lies in creating tailored solutions to meet the unique needs of different industries. For the medical industry, where precision and reliability are crucial, Rapid Manufacturing Inc manufactures wire & cable harnesses for devices like patient monitoring systems. These harnesses need to be extremely reliable as they are used to transmit vital health data. In the aerospace industry, the wire & cable harnesses it produces are used in aircraft avionics systems. They must be able to withstand extreme conditions such as high - altitude temperature variations and electromagnetic interference. The company's state - of - the - art manufacturing facilities enable it to produce high - quality harnesses with tight tolerances, ensuring seamless connectivity in complex electronic systems.

Electro - mechanical Assemblies

In the realm of electro - mechanical assemblies, Rapid Manufacturing Inc stands out with its advanced technological capabilities. It combines electrical and mechanical components to create highly functional assemblies. The company uses the latest CAD/CAM (Computer - Aided Design/Computer - Aided Manufacturing) technologies to design and produce electro - mechanical assemblies. This allows for precise control over the manufacturing process, resulting in products with high accuracy and repeatability. Quality control is a top priority. Each electro - mechanical assembly undergoes rigorous testing, including functional testing, durability testing, and environmental testing. For example, assemblies used in industrial machinery are tested to ensure they can operate smoothly under heavy - duty usage and harsh environmental conditions such as dust, moisture, and vibration.

Box Build Assemblies

When it comes to box build assemblies, Rapid Manufacturing Inc offers comprehensive solutions. The company's box build assemblies are known for their high - quality enclosures that provide excellent protection for internal components. These enclosures are designed to be both rugged and aesthetically pleasing. They can be customized in terms of size, shape, and material to fit different applications. For instance, in the semiconductor industry, where components need to be protected from electrostatic discharge (ESD), the box build assemblies are made with ESD - safe materials. Rapid Manufacturing Inc also provides value - added services such as component sourcing, testing, and final system integration. This one - stop - shop approach saves customers time and effort, as they can rely on Rapid Manufacturing Inc for the entire box build assembly process, from design to delivery.

Material Management and Production Flow

Streamlining the Supply Chain

Rapid Manufacturing Inc has a team of highly experienced material experts who play a crucial role in optimizing the supply chain. They have an in - depth understanding of the market dynamics of various raw materials and components required for their products. For example, in the procurement of wires and cables, they analyze multiple suppliers based on factors such as quality, price, and delivery time. By doing so, they are able to source the best - quality materials at competitive prices.

The company also implements a Just - in - Time (JIT) inventory system. The JIT system ensures that materials arrive at the production facility exactly when they are needed, minimizing inventory holding costs. For instance, if a batch of wire harnesses is scheduled for production on a specific day, the required wires, connectors, and other components will be delivered to the production line just in time, eliminating the need for large - scale warehousing of excess inventory. This not only reduces the capital tied up in inventory but also minimizes the risk of material obsolescence.

Minimizing Lead Times and Costs

Thanks to its efficient material management and production flow, Rapid Manufacturing Inc has achieved remarkable results in reducing lead times and costs. In the past five years, the company has managed to reduce the average lead time for custom - designed wire & cable harnesses by 30%. For example, what used to take 20 days to produce and deliver can now be completed in just 14 days.

In terms of cost reduction, the company has seen a 25% decrease in material - related costs. This is achieved through effective supplier negotiation, JIT inventory management, and minimizing waste in the production process. For electro - mechanical and box build assemblies, similar improvements have been made. The lead time for these products has been reduced by 20%, and the overall production cost has decreased by 20% as well, making Rapid Manufacturing Inc a more competitive and efficient player in the electronics manufacturing industry.

Yigu Technology's Viewpoint

As a non - standard plastic and metal products custom supplier, Yigu Technology highly values the expertise of Rapid Manufacturing Inc. In the field of electronic manufacturing, Rapid Manufacturing Inc's focus and experience are truly remarkable. Yigu Technology, in its own domain of non - standard customization, is constantly striving to enhance its technical capabilities and service quality. The concept of rapid manufacturing, with its emphasis on efficiency and customization, resonates with Yigu Technology's pursuit. We believe that there are potential areas for cooperation, such as in material innovation and process improvement. By sharing experiences and exploring new technologies together, we can better serve our respective customers and contribute to the development of the manufacturing industry as a whole.

FAQ

What industries does Rapid Manufacturing mainly serve?

Rapid Manufacturing mainly serves industries such as Medical, Aerospace, Semiconductor, Industrial, Defence, and Renewable Energy. In the medical industry, its products are used in crucial equipment like MRI machines and surgical robots due to the high - reliability requirements. In aerospace, components from Rapid Manufacturing are part of critical aircraft systems, ensuring flight safety and performance. The semiconductor industry benefits from its high - precision manufacturing capabilities for components that require tight tolerances. The industrial sector uses its products in various machinery, and the defence industry relies on its reliable and high - quality parts for military equipment. The renewable energy industry also takes advantage of its manufacturing expertise for components in solar panels, wind turbines, etc.

How does Rapid Manufacturing ensure product quality?

Rapid Manufacturing ensures product quality through several means. It has a team of highly skilled and experienced professionals who are well - versed in the latest manufacturing techniques and quality standards. The company implements strict quality control measures throughout the production process, from raw material inspection to final product testing. For example, in the production of wire & cable harnesses, all incoming wires and connectors are thoroughly inspected for quality. Advanced testing equipment is used to conduct functional, durability, and environmental tests on products. Each electro - mechanical and box build assembly undergoes rigorous quality checks to ensure they meet the highest industry standards.

What is the advantage of Rapid Manufacturing's material management?

The material management of Rapid Manufacturing has significant advantages. Its experienced material experts can optimize the supply chain by carefully selecting suppliers based on quality, price, and delivery time. By implementing a Just - in - Time (JIT) inventory system, it can minimize inventory holding costs. This system ensures that materials arrive exactly when needed for production, reducing the need for large - scale warehousing of excess inventory. As a result, it not only reduces the capital tied up in inventory but also minimizes the risk of material obsolescence. This efficient material management ultimately helps in reducing lead times and production costs, making the company more competitive in the market.