1. Introduction

1.1 Definition of Rapid Prototyping Engineering

Rapid prototyping engineering, based on the principle of discrete accumulation forming, is a technology that can directly convert a CAD model into a physical part. It enables the quick production of a prototype, providing a tangible representation of a design concept in a relatively short time.

2. Key Technologies in Rapid Prototyping Engineering

2.1 3D Printing (FDM, SLA, SLS)

3D printing has revolutionized rapid prototyping with several distinct techniques.

Fused Deposition Modeling (FDM) works by heating a thermoplastic filament until it becomes molten. A nozzle then extrudes the melted material layer by layer, following the digital model's cross - sectional data. For example, in a desktop 3D printer, an ABS or PLA filament is commonly used. This technique is popular for its simplicity and relatively low - cost operation.

Stereolithography (SLA) uses a laser to cure liquid photopolymer resin layer by layer. When the ultraviolet laser beam scans the surface of the resin, the exposed resin solidifies, creating a cross - section of the model. It is highly precise and can produce smooth - surfaced prototypes, making it ideal for jewelry design and medical model making.

Selective Laser Sintering (SLS) employs a high - power laser to sinter powdered materials, such as nylon or metal powders. The laser fuses the powder particles together in the areas corresponding to the model's cross - section, and after each layer is completed, a new layer of powder is spread for the next sintering process. It is suitable for creating complex and functional prototypes.

Here is a comparison table of these three 3D printing technologies:

| Technology | Precision | Material Applicability | Cost |

| FDM | Moderate, usually around 0.1 - 0.4mm layer thickness | Mainly thermoplastics like ABS, PLA | Low - cost equipment and materials |

| SLA | High, can achieve layer thickness as low as 0.025mm | Photopolymer resins | Higher equipment cost, medium - cost resins |

| SLS | Medium - high, with layer thickness typically 0.08 - 0.15mm | Wide range including nylon, metal, ceramic powders | High - cost equipment, medium - high material cost |

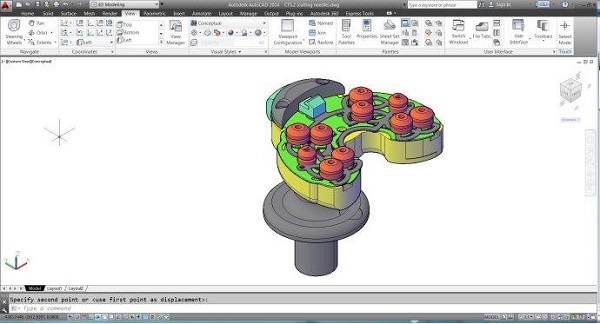

2.2 CNC Machining

CNC (Computer Numerical Control) machining plays a crucial role in rapid prototyping engineering. It involves using pre - programmed computer software to control the movement of factory tools and machinery. In rapid prototyping, CNC machining can produce high - precision parts. For instance, in the aerospace industry, when developing a new engine component prototype, CNC machining can accurately carve the complex shape of the part from a solid block of metal.

The advantages of CNC machining include high precision, often achieving tolerances within ±0.001 inches (±0.025 mm), and the ability to process complex shapes. However, it has limitations. The cost is relatively high, especially for small - batch production, as it requires expensive equipment and skilled operators. Also, the processing time can be long, especially for intricate parts.

2.3 Injection Molding

Injection molding is a common method for manufacturing plastic prototypes. The process begins with melting plastic pellets in a heated barrel. Then, the molten plastic is injected under high pressure into a mold cavity that has the shape of the desired part. After the plastic cools and solidifies in the mold, the mold opens, and the finished part is ejected.

This method is highly suitable for mass production. Once the mold is created, a large number of identical parts can be produced quickly. For example, the production of plastic toy parts or consumer electronics housings. However, the initial cost of mold making is high. Design changes during the prototyping stage can also be costly as they may require the mold to be modified or remade.

3. Applications across Industries

3.1 Automotive Industry

In the automotive industry, rapid prototyping engineering plays a crucial role. For engine components, 3D printing, a key technology in rapid prototyping, has been widely adopted. For example, some automotive manufacturers use SLS technology to produce engine intake manifolds. By using this technology, they can optimize the internal structure of the intake manifold, improving the air - fuel mixture's flow and ultimately enhancing the engine's performance. According to industry data, engines with 3D - printed intake manifolds can increase fuel efficiency by about 5% compared to traditional ones.

When it comes to interior components, FDM 3D printing is often used to create prototypes. For instance, the design of a new car's dashboard can be quickly transformed into a physical prototype through FDM 3D printing. This allows designers to evaluate the ergonomics, aesthetics, and functionality of the dashboard design in a short time. It also enables rapid design iterations, reducing the overall development time of the vehicle interior. In the past, developing a new dashboard design could take months, but with rapid prototyping, it can be shortened to a few weeks.

3.2 Aerospace Industry

The aerospace industry heavily relies on rapid prototyping engineering for the production of complex components. Take aircraft engine blades as an example. These blades need to withstand extremely high temperatures and mechanical stresses during flight. With rapid prototyping technologies like selective laser melting (SLM), manufacturers can create engine blades with complex internal cooling channels. These channels are designed to improve the blade's heat dissipation efficiency, enhancing the blade's performance and lifespan.

The use of rapid prototyping in the aerospace industry significantly shortens the research and development cycle. A case in point is that in the past, developing a new type of engine blade might take years. However, with the application of rapid prototyping technologies, this period can be reduced by at least 30%. This not only speeds up the development of new aircraft models but also allows aerospace companies to respond more quickly to market demands and technological advancements.

3.3 Medical Field

In the medical field, rapid prototyping engineering has brought revolutionary changes, especially in the production of personalized medical devices. For personalized prosthetics, 3D scanning technology is first used to obtain the patient's residual limb data. Then, based on this data, a customized prosthetic is designed using CAD software and manufactured through 3D printing. This ensures a perfect fit for the patient, improving their mobility and quality of life.

For implant manufacturing, SLA 3D printing is often utilized to produce high - precision implants. For example, a patient - specific dental implant can be created. By accurately matching the patient's jawbone structure, the implant can better integrate with the surrounding tissue, reducing the risk of rejection and improving the success rate of the implant surgery. It is estimated that the use of personalized implants made by rapid prototyping can increase the success rate of implant surgeries by about 15% compared to traditional implants.

5. Yigu Technology's Perspective

As a non - standard plastic metal products custom Supplier, Yigu Technology has rich experience in rapid prototyping engineering. Equipped with advanced 3D printers, CNC machining centers, and injection molding machines, we can handle a wide range of prototyping projects.

Our professional engineering team consists of skilled technicians and experienced designers. They are proficient in various rapid prototyping technologies and can provide customized solutions according to different customer needs. Whether it's a complex aerospace component or a personalized medical device prototype, we are committed to delivering high - quality products within the shortest time possible. Our one - stop service, from design to production, ensures that customers can get the most satisfactory results, saving both time and cost.

6. FAQs about Rapid Prototyping Engineering

6.1 What materials can be used in rapid prototyping engineering?

A variety of materials can be used in rapid prototyping engineering. Plastics like ABS, PLA, and nylon are commonly used in FDM 3D printing. ABS is known for its strength and heat resistance, making it suitable for functional prototypes in automotive or electronics industries. PLA is more environmentally friendly and easier to print, often used for art and design prototypes.

Metals such as aluminum, titanium, and stainless steel can be processed through techniques like selective laser melting (SLM) in metal 3D printing. These metals are used for high - performance components in aerospace and automotive industries due to their strength - to - weight ratio and durability.

Resins are mainly used in SLA and DLP 3D printing. They can create highly detailed and smooth - surfaced prototypes, which are ideal for jewelry, dental, and small - scale product design. Different materials are suitable for different rapid prototyping techniques and application scenarios, so material selection depends on the specific requirements of the prototype.

6.2 How accurate is the rapid prototyping process?

The accuracy of the rapid prototyping process is influenced by the technology and equipment used. For FDM 3D printing, the layer thickness, which affects accuracy, is generally in the range of 0.1 - 0.4mm. This means that the smallest feature size it can reproduce with high accuracy is limited within this range.

SLA 3D printing is much more precise, with a layer thickness that can reach as low as 0.05mm. It can create extremely fine details, making it suitable for applications where high precision is required, such as jewelry design and micro - mechanical parts prototyping.

CNC machining is also highly accurate, often achieving tolerances within ±0.001 inches (±0.025 mm). It can produce parts with very tight tolerances, meeting the high - precision requirements of aerospace and medical device industries.

6.3 What is the typical cost range for rapid prototyping services?

The cost of rapid prototyping services is affected by multiple factors, including materials, model complexity, and the chosen manufacturing process. For simple FDM 3D - printed plastic prototypes, if using common materials like PLA, the cost can be relatively low, starting from a few dollars for small, simple models. However, if the model has complex geometries that require more support structures during printing, the cost will increase.

For SLA - printed resin prototypes, due to the higher - cost resins and more complex equipment, the cost is generally higher than FDM. A small to medium - sized SLA - printed prototype might cost from tens to hundreds of dollars.

CNC - machined prototypes are usually more expensive, especially when using high - cost metals and for complex parts. The cost can range from hundreds to thousands of dollars, considering factors like machining time, tool wear, and material cost. Injection molding has a high initial cost for mold making, which can range from several thousand to tens of thousands of dollars, but the per - unit cost for mass - produced parts is relatively low.