If you’ve ever wondered how everyday items like car parts, aluminum cans, or even metal brackets are made, chances are forming machining plays a key role. Unlike subtractive machining (which cuts away material), forming machining shapes materials through plastic deformation—meaning the material bends, stretches, or compresses without breaking. This method is everywhere in manufacturing, but with so many processes, materials, and tools involved, it’s easy to feel overwhelmed.

In this guide, we’ll break down everything you need to know about forming machining: from the two main process categories to material-specific techniques, essential tools, and how it compares to other manufacturing methods. We’ll also share real-world examples and practical insights to help you decide if forming machining is right for your project.

What Is Forming Machining, and Why Does It Matter?

At its core, forming machining is a group of manufacturing processes that reshape solid materials (most often metals) using force—without removing any material (or removing very little). The key here is plastic deformation: when the material is pushed beyond its elastic limit, it keeps its new shape permanently.

Why is this important? For one, it’s incredibly efficient. Unlike drilling or milling (which generate scrap), forming minimizes waste and maximizes material use. It also improves the material’s strength: processes like rolling or forging align the metal’s grain structure flow, making parts more durable than those made with subtractive methods.

Real-World Example: Think about a stainless steel spoon. Instead of carving it from a block of steel (which would waste material), manufacturers use a stamping process—pressing a flat metal sheet into a spoon shape. This is forming machining in action: fast, cost-effective, and strong.

The Two Main Categories of Forming Machining Processes

Forming machining isn’t a one-size-fits-all method. It’s split into two primary categories, each designed for different materials (bulk vs. sheet) and end products. Let’s dive into each, with practical use cases for clarity.

1. Bulk Forming Processes: Shaping Solid Blocks or Ingots

Bulk forming focuses on reshaping thick, solid materials like metal bars, ingots, or billets. The goal is to compress or squeeze the material into a new shape—think of it like molding clay, but with metal. Key processes here include:

- Forging: Using hammers or presses to pound hot or cold metal into shape. Hot forging (done at temperatures above the metal’s recrystallization point) is ideal for large parts like crankshafts, while cold forging (room temperature) works for small, precise parts like bolts.Case Study: A heavy equipment manufacturer uses hot forging to make excavator bucket teeth. Forging aligns the steel’s grain structure, making the teeth 30% more resistant to wear than cast alternatives (per data from the American Forging Association).

- Rolling: Passing metal through pairs of rotating rolls to reduce thickness or create shapes (like I-beams or sheets). Hot rolling (used for structural steel) softens the metal, while cold rolling (used for aluminum foil) creates a smooth, precise finish.

- Extrusion: Pushing metal through a die (a custom-shaped opening) to create long, uniform parts like aluminum window frames or heat sinks.

- Drawing: Pulling metal through a die to make thin wires (like copper electrical wire) or tubes.

All these processes rely on hot working (high temperatures) or cold working (room temperature). Hot working makes materials easier to shape and reduces internal stress, while cold working strengthens parts through work hardening (the material gets harder as it’s deformed).

2. Sheet Metal Forming Processes: Shaping Thin Metal Sheets

Sheet metal forming is for thin, flat metal sheets (usually less than 6mm thick). It’s perfect for making parts with complex shapes—like car body panels, food cans, or computer cases. Common processes include:

- Bending: Using a press brake to fold sheet metal into angles (e.g., making a metal bracket with a 90-degree bend). A challenge here is springback—the metal slightly reverts to its original shape after bending. To fix this, manufacturers often over-bend the material by a small amount.Practical Tip: For aluminum sheets (which have high springback), use a “bottoming” technique—pressing the metal all the way to the die—to reduce springback by up to 80%.

- Stamping: Using a punch and die to cut or shape sheet metal in one step. It’s used for high-volume parts like washers or car door handles.

- Deep Drawing: Pulling a sheet metal blank into a die to make hollow parts (e.g., aluminum cans or stainless steel pots). The depth of the part can be several times the diameter of the blank—hence “deep” drawing.

- Shearing/Punching/Blanking: Cutting sheet metal into specific shapes. Shearing uses blades (like scissors) to cut straight lines, while punching creates holes (e.g., in a metal shelf). Blanking cuts out a specific shape (the “blank”) that’s used for further forming.

To help you compare these processes, here’s a quick reference table:

| Process | Key Use Case | Material Thickness | Common Metals Used |

|---|---|---|---|

| Bending | Brackets, frames | 0.5–6mm | Steel, aluminum |

| Stamping | Washers, car parts | 0.1–3mm | Steel, copper |

| Deep Drawing | Cans, pots, hydraulic cylinders | 0.2–2mm | Aluminum, steel |

| Shearing | Cutting sheets to size | 0.1–10mm | Steel, stainless steel |

Material-Specific Forming: Matching Processes to Metals

Not all metals behave the same way during forming. A process that works for aluminum might not work for titanium, which is why material-specific forming is critical. Let’s break down the most common metals and the forming methods designed for them:

- Steel (Forging Steel): Steel is strong and durable, making it ideal for forging. Hot forging is used for large, load-bearing parts (like truck axles), while cold forging makes small, high-strength parts (like screws).

- Aluminum (Aluminum Extrusion): Aluminum is lightweight and easy to extrude. Extrusion is the go-to process for aluminum parts like window frames, bike frames, or heat sinks—since it can create complex cross-sections quickly.

- Titanium (Titanium Superplastic Forming): Titanium is strong but brittle at room temperature. Superplastic forming (heating titanium to 800–900°C, where it becomes flexible) lets manufacturers shape it into complex parts for aerospace (like jet engine components).

- Hydroforming: This process uses high-pressure fluid (usually oil or water) to press metal into a die. It’s great for metals that are hard to form with traditional methods, like stainless steel or brass. Hydroforming is used to make car exhaust systems or bicycle frames, as it creates smooth, uniform shapes with no seams.

- Powder Metallurgy (P/M) & Metal Injection Molding (MIM): For small, complex parts (like watch gears or medical implants), P/M and MIM are ideal. P/M presses metal powder into a die and then sintering (heating it to bond the powder). MIM mixes metal powder with plastic, injects it into a mold, and sinters it—perfect for tiny, intricate parts.

Key Fact: According to the Metal Powder Industries Federation, MIM can produce parts with tolerances as tight as ±0.1mm—making it 50% more precise than traditional machining for small components.

Essential Forming Tools and Equipment

You can’t do forming machining without the right tools. The equipment you use depends on the process, but here are the most critical tools and what they do:

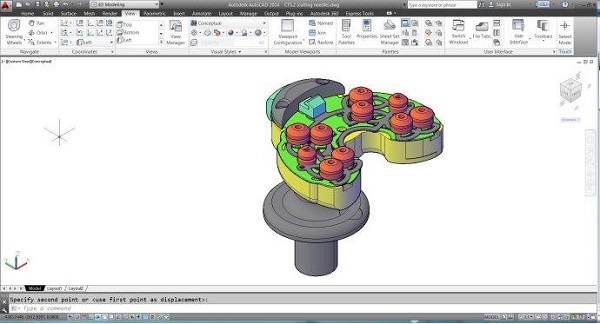

- Dies & Molds: These are custom-shaped tools that give the material its final form. A die for extrusion has a hole in the shape of the part (e.g., a square for a aluminum rod), while a mold for MIM is a cavity that holds the metal-plastic mixture.

- Presses: Presses apply force to shape the material. They come in different sizes: small bench presses (for hobby projects) to high-tonnage machinery (up to 10,000 tons) for forging large parts like ship propellers.

- Hammers: Used in forging to strike hot metal. Drop hammers (which use gravity) are for heavy-duty forging, while air hammers are more precise for smaller parts.

- Rolls: Used in rolling processes. Two or more rolls rotate to squeeze the metal into shape—flat rolls for sheets, and shaped rolls for I-beams.

- Mandrels: These are cylindrical tools used in drawing or extrusion to create holes in parts (e.g., making a metal tube instead of a solid rod).

- Tool and Die Making: This is the process of creating dies and molds themselves. It requires precision machining (like CNC milling) to ensure the dies are accurate—since even a 0.1mm error can ruin thousands of parts.

Expert Insight: Investing in high-quality dies pays off. A well-made steel die can last for over 100,000 cycles (parts produced), while a low-quality die might fail after 10,000 cycles—adding significant cost to production.

Forming Machining vs. Other Methods: Advantages and Tradeoffs

Why choose forming machining over subtractive machining (like milling or turning) or additive manufacturing (like 3D printing)? Let’s break down its key advantages and when it’s the best choice:

Key Advantages of Forming Machining

- High Production Rate: Processes like stamping or extrusion can produce hundreds of parts per minute—perfect for mass production (e.g., aluminum cans).

- Material Savings: Since forming doesn’t cut away material, it reduces scrap by up to 90% compared to subtractive machining (per the Society of Manufacturing Engineers).

- Net-Shape/Near-Net-Shape: Many forming processes create parts that need little to no finishing (called “net-shape”). This saves time and money—for example, a forged crankshaft only needs a quick polish before use.

- Improved Mechanical Properties: Forming aligns the metal’s grain structure, making parts stronger and more resistant to fatigue. A forged steel part can have up to 20% higher tensile strength than a cast part.

- Cost-Effective for Large Batches: While tooling (dies, molds) can be expensive upfront, forming becomes cheaper per part when producing thousands of units.

When to Choose Something Else

- Small Batches: For 1–100 parts, additive manufacturing (3D printing) is better—since you don’t need to pay for expensive tooling.

- Complex Internal Features: Subtractive machining (like CNC milling) is better for parts with holes or channels that are hard to reach with forming.

To make it easier to decide, here’s a comparison table:

| Method | Best For | Cost Per Part (High Volume) | Strength | Scrap Rate |

|---|---|---|---|---|

| Forming Machining | Mass-produced, strong parts | Low ($0.10–$5) | High | Low (<5%) |

| Subtractive Machining | Small batches, complex parts | High ($5–$50) | Medium | High (20–50%) |

| Additive Manufacturing | Prototypes, small batches | Very High ($50–$500) | Low-Medium | Low (<10%) |

Yigu Technology’s Perspective on Forming Machining

At Yigu Technology, we see forming machining as a cornerstone of modern manufacturing—especially as industries like automotive and aerospace push for lighter, stronger, and more sustainable parts. We’ve worked with clients to optimize forming processes: for example, helping an electric vehicle (EV) maker switch from subtractive machining to hydroforming for battery trays. This change cut scrap by 85% and improved the tray’s strength by 15%—critical for EV safety.

We also believe that the future of forming machining lies in automation and material innovation. Integrating AI into press controls can reduce springback errors by up to 40%, while new materials (like high-strength aluminum alloys) are making forming even more versatile. For manufacturers, the key is to match the right forming process to their material and production goals—something our team helps with every day.

FAQ: Common Questions About Forming Machining

1. What’s the difference between hot working and cold working in forming?

Hot working is done at temperatures above the metal’s recrystallization point (e.g., 1,200°C for steel), making the metal soft and easy to shape. It reduces internal stress but can leave a rough surface. Cold working is done at room temperature—it strengthens parts via work hardening but can cause springback.

2. Can forming machining be used for non-metallic materials?

Yes! While it’s most common for metals, forming also works for plastics (injection molding), glass (blowing), and even ceramics (pressing and sintering). The process varies slightly, but the core idea—shaping via force—stays the same.

3. How much does it cost to start using forming machining?

It depends on the process. A small press brake for bending sheet metal can cost $10,000–$50,000, while a high-tonnage forging press can cost $500,000–$2 million. For small businesses, outsourcing initial tooling (dies/molds) can reduce upfront costs.

4. Is forming machining environmentally friendly?

Yes, compared to subtractive machining. It produces less scrap (which reduces waste) and uses less energy per part—since shaping material with force is more efficient than cutting it. Many manufacturers also recycle the small amount of scrap that is generated.

5. What’s the most precise forming process?

Metal Injection Molding (MIM) is the most precise, with tolerances as tight as ±0.1mm. It’s ideal for tiny parts like medical implants or watch components where precision is critical.