If you’re in manufacturing, aerospace, or medical device production, you’ve probably asked: How do we make complex parts faster, more precisely, and with fewer errors? The answer often lies in advanced machining—a set of technologies that’s revolutionizing how we shape materials from titanium alloys to delicate ceramics.

This guide isn’t just a list of terms. It’s a practical resource built around real-world challenges. We’ll start with the core processes, move to ways to boost efficiency, dive into automation tools, explore precision techniques, and wrap up with smart systems that adapt on the fly. By the end, you’ll know which advanced machining methods fit your needs—and how to implement them.

1. Advanced & Hybrid Processes: Beyond Traditional Cutting

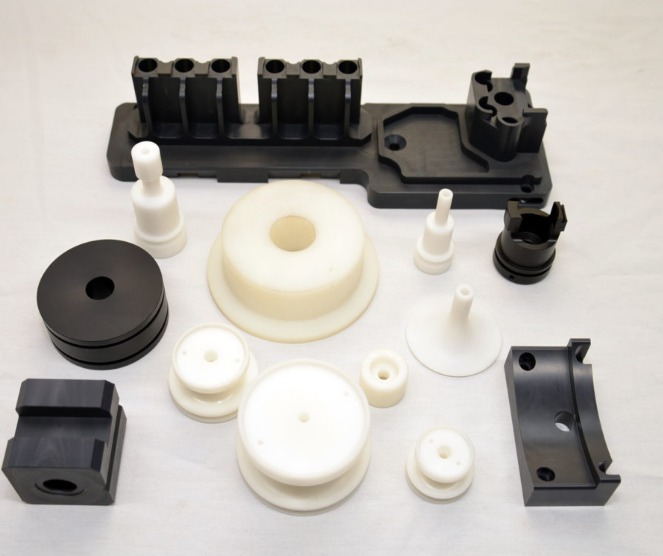

Traditional machining (like milling or turning) relies on physical tools touching materials. But when you’re working with super-hard metals (e.g., Inconel) or fragile components (e.g., glass for semiconductors), those methods fall short. That’s where advanced & hybrid processes come in—they use energy (lasers, water, electrons) or chemistry to shape materials without heavy contact.

Let’s break down the most useful techniques, with examples of when to use each:

| Process | How It Works | Ideal Applications | Real-World Example |

| Abrasive Waterjet Machining (AWJM) | High-pressure water (up to 90,000 psi) mixed with abrasive particles (e.g., garnet) cuts through materials. | Thick metal plates, stone, or composite materials (no heat damage). | A construction company used AWJM to cut 6-inch-thick stainless steel panels for a skyscraper’s facade—avoiding warping that would have happened with laser cutting. |

| Laser Beam Machining (LBM) | A focused laser beam (e.g., CO₂ or fiber laser) melts or vaporizes material. | Precision cutting of thin metals, engraving, or drilling tiny holes. | A medical device maker used LBM to drill 0.1mm holes in titanium surgical needles—holes too small for mechanical drills to create consistently. |

| Electrochemical Machining (ECM) | A conductive fluid (electrolyte) and an electrode remove material through chemical reactions (no physical contact). | Shaping hard metals like titanium or nickel alloys for aerospace parts. | Boeing uses ECM to shape turbine blades for jet engines—achieving smooth surfaces that reduce air resistance and improve fuel efficiency. |

The next evolution? Hybrid Manufacturing—combining two or more processes to fix their weaknesses. For example, Additive & Subtractive Combination (3D printing a part, then using milling to smooth its surface) lets you create complex shapes and get the precision of traditional machining. A Formula 1 team used this hybrid method to make engine parts: 3D printing reduced weight by 30%, while milling ensured the parts fit perfectly with other components.

2. High-Performance & High-Efficiency Strategies: Do More, Faster

Advanced machining isn’t just about new tools—it’s about using them smarter. High-Performance & High-Efficiency Strategies help you cut production time, reduce waste, and lower costs without sacrificing quality. Let’s look at the most impactful ones:

- High-Speed Machining (HSM): Cutting at speeds 5–10x faster than traditional methods (e.g., 10,000 RPM for aluminum). It works because faster cuts reduce heat buildup (since the tool spends less time on the material). A furniture manufacturer switched to HSM for aluminum frames—cutting production time from 2 hours per frame to 20 minutes, and reducing tool wear by 40%.

- Hard Turning: Machining metals with a hardness of 45+ HRC (e.g., hardened steel) using cubic boron nitride (CBN) tools—instead of grinding. It’s faster and more precise than grinding. A automotive parts maker used hard turning for brake rotors: they eliminated a separate grinding step, cutting lead time by 30% and saving $5 per rotor.

- High-Pressure Coolant (HPC): Spraying coolant at 1,000+ psi directly at the cutting area. This cools the tool and flushes away chips (small pieces of material), preventing them from scratching the part. A metal fabrication shop added HPC to their milling machines—reducing tool breakage by 50% and improving surface finish quality (fewer scratches meant less rework).

Two strategies to eliminate waste:

- Lean Manufacturing: Cutting out unnecessary steps (e.g., reducing inventory or simplifying setup). A electronics company used Lean to streamline their machining process for smartphone casings—they cut setup time from 1 hour to 15 minutes by standardizing tool placement, and reduced material waste by 25% by reusing scrap aluminum.

- Agile Manufacturing: Adapting quickly to design changes. A custom bike maker uses Agile: when a customer requests a different frame size, their machining team can reprogram tools in 30 minutes (instead of 2 hours) and start production the same day. This helped them increase customer satisfaction by 60%.

3. Automation & Digitalization: Let Technology Do the Heavy Lifting

The biggest time drain in machining? Manual work—loading parts, moving them between machines, or checking for errors. Automation & Digitalization solve this by letting machines handle repetitive tasks, while software tracks and optimizes performance.

Here’s how to automate key parts of your workflow:

| Technology | What It Does | Benefit for Your Shop |

| Industrial Robotics | Robotic arms load/unload parts, change tools, or inspect finished products. | Runs 24/7 without breaks. A metal shop added 2 robotic arms to their milling machines—they now produce 3x more parts per day, and eliminated injuries from lifting heavy metal blocks. |

| Automated Guided Vehicles (AGVs) | Self-driving carts move parts between machines (e.g., from a 3D printer to a milling machine). | Reduces human error (no more parts left in the wrong place). A aerospace supplier used AGVs to move engine components—they cut delivery time between machines by 40% and eliminated 90% of misplaced parts. |

| Digital Twin | A virtual copy of your machining system (machines, tools, parts). You can test changes (e.g., new tool paths) in the virtual world before using them in real life. | Reduces downtime. A automotive plant used a digital twin to test a new tool path for car axles—they fixed a potential collision issue in the virtual system, avoiding a 4-hour shutdown that would have cost $10,000. |

The end goal? Lights-Out Manufacturing—running your shop 24/7 without any human workers (night shifts, weekends). A precision parts maker in Japan uses this: their machines are monitored by IoT Sensors (track temperature, vibration, tool wear) and Real-Time Monitoring software. If a machine has an issue, the software sends an alert to a technician’s phone. They’ve increased production by 80% and cut labor costs by 50%.

4. Precision & Micro-Machining: Making the “Impossible” Parts

Some industries—like medical devices or semiconductors—need parts so small or precise that even a hair’s width of error ruins them. That’s where Precision & Micro-Machining comes in. We’re talking about Sub-Micron Tolerances (errors smaller than 1 micrometer—1/1000th of a millimeter) and Miniature Components (parts smaller than a grain of rice).

Let’s explore the key techniques:

- Ultra-Precision Machining: Using machines with vibration control and high-resolution sensors to achieve tolerances as tight as 0.1 micrometers. A semiconductor company uses this to make wafer chucks (parts that hold silicon wafers)—even a tiny error would cause the wafer to break during processing.

- Single-Point Diamond Turning (SPDT): Using a diamond tool to cut materials like aluminum or copper into smooth surfaces (e.g., mirrors for telescopes). The diamond’s hardness ensures no tool wear, so every part is identical. A optics manufacturer used SPDT to make mirrors for a satellite—these mirrors have a surface finish so smooth that they can focus light from distant stars.

- Vibration Control: Even small vibrations (e.g., from a nearby machine) can ruin a precise cut. Solutions include:

- Floating floors (isolate the machining area from the rest of the shop).

- Active vibration dampers (sensors detect vibration and send counter-forces to cancel it out).

A real example: A medical device maker needed to create micro-milling channels (0.2mm wide) in a stainless steel insulin pump. They used a micro-milling machine with vibration control and a 0.1mm diameter tool. The result? Channels that were consistent across 10,000 parts—no rework needed.

5. Smart Machining & Adaptive Control: Machines That Learn and Adjust

The biggest frustration in machining? Unexpected errors—like a tool wearing out mid-cut, or a material being harder than expected. Smart Machining & Adaptive Control fixes this by letting machines “think” for themselves: they monitor conditions in real time and adjust settings to avoid mistakes.

Here’s how it works:

- AI-Powered Optimization: Machine learning algorithms analyze data (e.g., tool wear, cutting speed) to find the best settings. A metal shop used AI to optimize their milling process for steel parts—the algorithm suggested increasing speed by 15% and reducing feed rate by 5%, which cut tool wear by 30% and improved surface finish.

- Tool Condition Monitoring (TCM): Sensors on the tool or machine track wear (e.g., by measuring vibration or temperature). When the tool is close to failing, the system alerts the operator or automatically changes the tool. A automotive parts maker added TCM to their lathes—they reduced unexpected tool failures by 70% and eliminated 95% of defective parts caused by worn tools.

- Closed-Loop Systems: The machine measures the part while cutting (using In-Process Metrology) and adjusts the tool path if there’s an error. For example, if a part is 0.01mm smaller than needed, the system slows the cutting speed to remove less material. A aerospace supplier used closed-loop systems for turbine blades—they reduced tolerance errors by 80% and cut inspection time by 50% (since the part is checked during cutting, not after).

A case study: A defense contractor needed to machine titanium parts for missiles. Titanium’s hardness varies, so traditional machining often resulted in parts that were too big or too small. They added an Adaptive Control System that adjusted the cutting force based on the material’s hardness. The result? Defect rate dropped from 12% to 1%, and production time per part decreased by 18%.

Yigu Technology’s Perspective on Advanced Machining

Advanced machining is no longer a “nice-to-have”—it’s a necessity for manufacturers looking to stay competitive. At Yigu Technology, we’ve seen firsthand how combining hybrid processes (like additive + subtractive) with smart control systems transforms operations. For example, a client in the automotive industry used our AI-powered tool monitoring solution to reduce tool costs by 35% and increase output by 25%.

The future of advanced machining will be even more connected: digital twins will work with IoT sensors to predict issues before they happen, and agile manufacturing will let shops adapt to custom orders in hours, not days. Manufacturers who invest in these technologies now won’t just save money—they’ll be ready to tackle the next generation of challenges, from lightweight aerospace parts to micro-scale medical devices.

FAQ: Your Advanced Machining Questions Answered

Q1: What’s the difference between advanced machining and traditional machining?

Traditional machining uses physical tools (e.g., drills, mills) to cut material, which works for soft metals but struggles with hard or fragile materials. Advanced machining uses energy (lasers, water) or chemistry (ECM) to shape material, making it better for hard metals (titanium), fragile parts (glass), or tiny components (micro-milling).

Q2: Is advanced machining expensive?

It can have higher upfront costs (e.g., a laser cutter costs more than a traditional mill), but it saves money long-term. For example, hard turning eliminates the need for grinding machines, and automation reduces labor costs. Many shops see a return on investment (ROI) within 1–2 years.

Q3: Which advanced machining process is best for my business?

It depends on your materials and parts:

- Use AWJM for thick, hard materials (no heat damage).

- Use LBM for thin parts or tiny holes.

- Use hybrid manufacturing (additive + subtractive) for complex shapes that need precision.

Q4: How do I get my team trained on advanced machining?

Most equipment suppliers offer training (e.g., laser cutter manufacturers teach operators how to program and maintain the machine). Online courses (from platforms like Coursera or industry associations) also cover topics like digital twins and AI optimization. Many shops start with a small team of trained technicians, then scale up.

Q5: Will automation replace human workers in machining?

No—automation replaces repetitive tasks (loading parts, moving materials), but human workers are still needed to program machines, troubleshoot issues, and optimize processes. The best setups combine automation with skilled workers to get the highest efficiency.