Understanding SLA Printing Resolution

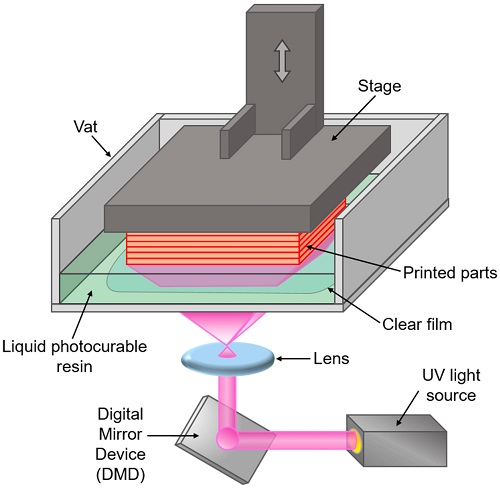

SLA (Stereolithography Apparatus) printing resolution is a crucial factor that significantly impacts the quality and precision of 3D printed objects. At its core, SLA printing resolution determines the level of detail that can be achieved in a printed model.

In SLA printing, the resolution is mainly measured in two aspects: layer thickness and XY resolution. Layer thickness refers to the vertical thickness of each individual layer that is cured during the printing process. A smaller layer thickness means that the printer can create more layers within the same height of the object. For example, if you have a layer thickness of 0.05mm, compared to 0.1mm, the printer will deposit twice as many layers for an object of the same height. This results in a smoother surface finish and better representation of fine vertical details.

On the other hand, XY resolution pertains to the horizontal detail, similar to the pixel density in a digital image. It determines how small and precise the features can be in the X and Y directions (the plane parallel to the build platform). A high XY resolution allows for the creation of intricate geometries, such as thin walls, small holes, and detailed surface textures. For instance, a printer with an XY resolution of 25μm can produce much finer details than one with 100μm resolution. The former can accurately reproduce tiny details like the fine engravings on a jewelry piece, while the latter may result in a more "chunky" or less detailed version of the same design.

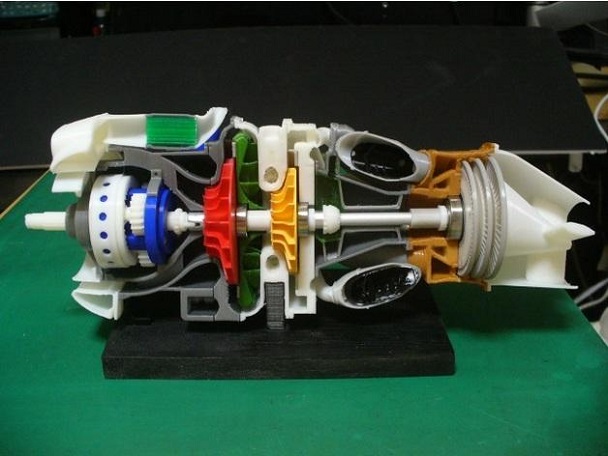

To better understand the importance of SLA printing resolution, consider the following examples. In the field of jewelry design, a high - resolution SLA printer can replicate the delicate filigree work and small gemstone settings with remarkable accuracy. Each curve and detail of the design can be faithfully reproduced, making it possible to create prototypes or even final products that are indistinguishable from traditional hand - crafted pieces.

In the medical field, when printing anatomical models for surgical planning, a high - resolution SLA print is essential. Precise details of bones, blood vessels, and soft tissues need to be captured accurately. A low - resolution print might miss crucial details, leading to inaccurate representations that could potentially affect surgical outcomes.

Factors Affecting SLA Printing Resolution

1. Laser Spot Size

The laser spot size is a fundamental factor influencing SLA printing resolution. In SLA printers, a laser beam is used to cure the resin layer by layer. The smaller the laser spot size, the more precisely it can target and solidify the resin. For instance, if the laser spot size is large, when creating a fine detail like a small protrusion on the model, the cured area will be larger than intended, blurring the edges and reducing the overall resolution. A small laser spot size, on the other hand, can accurately trace the shape of the protrusion, resulting in a sharp and well - defined feature. In high - end SLA printers, laser spot sizes can be as small as a few micrometers. Printers with such small laser spot sizes are capable of achieving resolutions that can create highly detailed miniatures, where even the tiniest facial features on a figurine can be accurately replicated.

2. Layer Thickness

Layer thickness is another crucial element in determining SLA printing resolution. When the layer thickness is thin, it significantly enhances the model's surface smoothness and detail representation. A thick layer will lead to a "stepped" appearance on the surface of the printed object, especially on curved surfaces. For example, if you are printing a spherical object with a layer thickness of 0.1mm, the surface will have visible steps, which are more pronounced as the curvature changes. However, if the layer thickness is reduced to 0.02mm, these steps become much less noticeable, resulting in a surface that is much closer to a smooth, continuous curve.

In addition, thin layers are essential for capturing fine vertical details. In a complex 3D model with small holes or channels running vertically, a thick layer might not be able to accurately represent the shape and size of these features. Thin layers, on the contrary, can follow the intricate design precisely, ensuring that all the details are faithfully reproduced.

Comparing SLA Printing Resolution with Other Printing Technologies

When it comes to 3D printing, different technologies offer various levels of resolution. Let's compare SLA printing resolution with some other common 3D printing technologies:

| Printing Technology | Layer Thickness Range | XY Resolution Range | Advantages in Resolution | Disadvantages in Resolution |

| SLA (Stereolithography Apparatus) | 0.02 - 0.1mm | 25 - 100μm | High - resolution in both layer thickness and XY directions, allowing for very fine details. Ideal for creating smooth surfaces and highly detailed models, such as jewelry prototypes, dental models, and intricate art pieces. | Limited build volume in some entry - level printers. Resin materials can be relatively expensive, and the post - processing steps, like resin removal and curing, are necessary. |

| FDM (Fused Deposition Modeling) | 0.1 - 0.4mm | 100 - 400μm | Lower cost compared to SLA. Widely available materials and easy to use, suitable for beginners. Good for creating functional prototypes and large - scale models where high - resolution details are not the primary concern. | Lower resolution in both layer thickness and XY directions. Results in a more "stepped" surface appearance due to relatively thick layers, and less precise fine details. |

| SLS (Selective Laser Sintering) | 0.06 - 0.15mm | 100 - 200μm | Can create strong and durable parts without the need for support structures as the unsintered powder acts as support. Good for functional parts and parts with complex internal geometries. | Lower resolution compared to SLA in terms of fine details. The surface finish is often rough, and the equipment and materials can be expensive. |

As shown in the table, SLA printing stands out in terms of its ability to achieve high - resolution prints with fine details. Its relatively small layer thickness and XY resolution make it the go - to choice for applications where precision and surface smoothness are crucial. However, each technology has its own niche, and the choice depends on the specific requirements of the project, such as cost, material properties, and the level of detail needed.

Yigu Technology's Viewpoint

As a non - standard plastic metal products custom Supplier, Yigu Technology highly values SLA printing resolution in the custom production process. High SLA printing resolution is crucial for achieving the precision and quality required in custom - made products. In the production of non - standard plastic products, a high - resolution SLA print can accurately replicate complex designs, ensuring that every detail of the custom - made part meets the client's specifications. For example, when creating small, intricate plastic components with fine grooves or detailed surface patterns, a high - resolution SLA printer can faithfully reproduce these features, resulting in a product with excellent dimensional accuracy and a smooth surface finish. This not only improves the aesthetic appeal of the product but also enhances its functionality. In the case of metal - like plastic products, high - resolution SLA printing can better simulate the texture and details of real metals, providing clients with high - quality prototypes or small - batch production parts that are closer to the final product requirements. Overall, SLA printing resolution directly impacts the competitiveness and value of custom - made products in the market.

FAQ

1. What is the highest achievable SLA printing resolution?

Theoretically, some high - end SLA printers can achieve an XY resolution as low as 25μm and a layer thickness as thin as 0.02mm. For example, certain industrial - grade SLA printers are designed to reach these high - resolution parameters, enabling the creation of extremely detailed 3D models with fine features and smooth surfaces. However, such high - resolution settings may also come with longer printing times and higher costs.

2. How does SLA printing resolution affect the cost of a 3D printed part?

Higher SLA printing resolution generally leads to increased costs. Printers capable of high - resolution printing are often more expensive to purchase and maintain. Additionally, high - resolution printing may require more time as the printer needs to deposit thinner layers and create finer details. Time is a cost factor, especially in commercial or production - oriented 3D printing. Moreover, high - resolution SLA printing might demand higher - quality and more expensive resin materials to ensure accurate curing and the desired level of detail.

3. Can SLA printing resolution be improved after the printing process?

After the SLA printing process, it is difficult to directly improve the printing resolution in the same sense as during the printing. However, post - processing techniques can enhance the appearance and smoothness of the printed part, which may give the impression of better resolution. For example, sanding and polishing can reduce the visibility of layer lines, making the surface smoother. Chemical treatments can also be used to refine the surface finish. But these methods do not actually increase the inherent resolution of the printed features in terms of the original layer thickness and XY resolution set during printing.